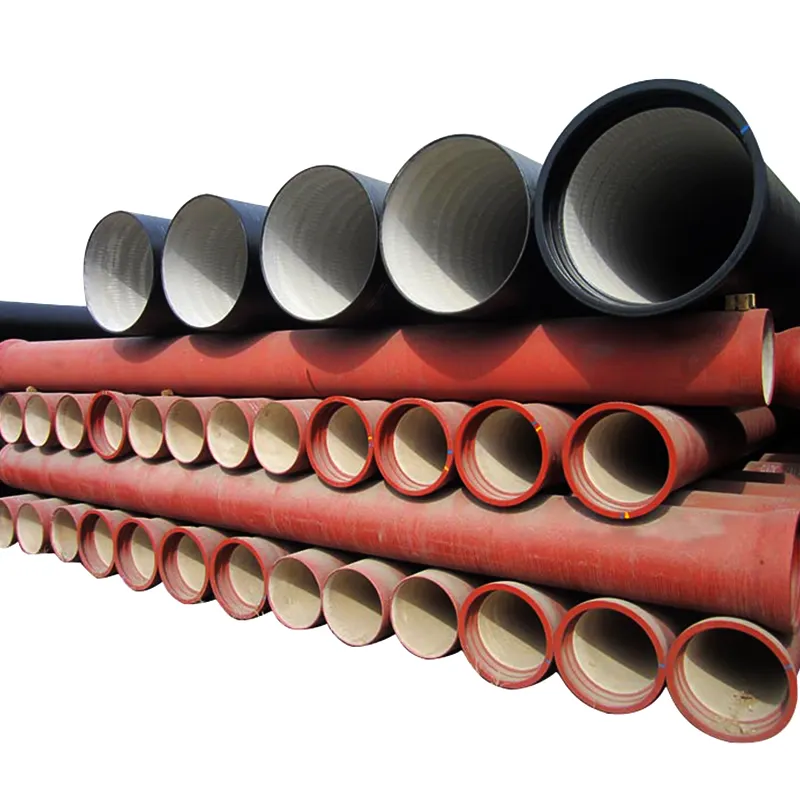

Ductile iron pipes play a vital role in today's infrastructure developments, particularly in water distribution networks and wastewater management systems across cities. Beyond municipal applications, these pipes find their way into various industrial settings where durability matters most. The material combines impressive tensile strength with remarkable flexibility, making it stand out compared to alternatives like PVC or steel. As communities strive for long-term sustainability goals, understanding why ductile iron remains a preferred choice for underground utilities becomes increasingly important for engineers and planners alike.

The Importance of Ductile Iron Pipes

Ductile iron pipes still stand out as a go to material for building both water distribution networks and sewage systems across the country. Compared to older cast iron alternatives, these pipes offer better performance because they withstand high pressures and fight off corrosion much longer. The fact that they last through tough conditions really matters for keeping water supplies reliable over time. Municipal engineers love working with them since they hold up against everything from underground moisture to chemical exposure in industrial areas. That's why so many cities continue choosing ductile iron despite newer options on the market.

Advantages Over Other Materials

When it comes to piping materials, ductile iron stands out compared to options like PVC or concrete mainly because of how tough it really is. With regular upkeep, these pipes often stick around well past 100 years. Another big plus? They're actually pretty straightforward to install since they resist cracking under stress and work just fine even when buried in softer soils where other materials might struggle. This makes laying them down faster and cheaper while still giving engineers peace of mind knowing their systems will keep functioning reliably decade after decade.

Environmental Impact and Sustainability

Ductile iron pipes stand out from other materials because they're made from recycled content right from the start, making them inherently sustainable. What's more, when these pipes reach the end of their service life, they can be fully recycled again, supporting the circular economy so many nations are pushing for today. Infrastructure replacement typically creates tons of waste and releases considerable carbon emissions. But ductile iron pipes last longer than most alternatives thanks to their exceptional strength and durability. Their ability to withstand harsh conditions means fewer replacements over time, reducing both material waste and environmental impact. Municipalities around the world are increasingly specifying these pipes for water systems precisely because they help meet modern sustainability goals without compromising structural integrity.

New Developments Related to Ductile Iron Pipe Technology

Ductile iron pipes keep getting better thanks to ongoing improvements in materials science. Recent breakthroughs in protective coatings and internal linings have significantly boosted their ability to resist corrosion from harsh environments. Manufacturers are now using innovative production techniques that result in pipes weighing about 15% less than traditional models, making handling and transport much simpler for crews on site. These enhancements not only extend the lifespan of the piping system but also cut down labor expenses during installation. Municipal water departments across the country are starting to notice these benefits firsthand, especially when replacing aging infrastructure in urban areas where every dollar saved counts toward future maintenance needs.

Trends for Different Industries Along With Future Predictions

As cities keep expanding across the globe, demand for durable piping solutions keeps rising right alongside the need for better water distribution networks and waste management systems. Both governments and businesses are pouring money into building new infrastructure in developing regions where population growth outpaces existing capacity. Ductile iron pipes have become particularly valuable for meeting today's infrastructure challenges because they combine strength with flexibility. Industry experts remain bullish about the future of these pipes too, since researchers continue exploring ways to improve corrosion resistance while finding new applications beyond traditional waterworks projects.