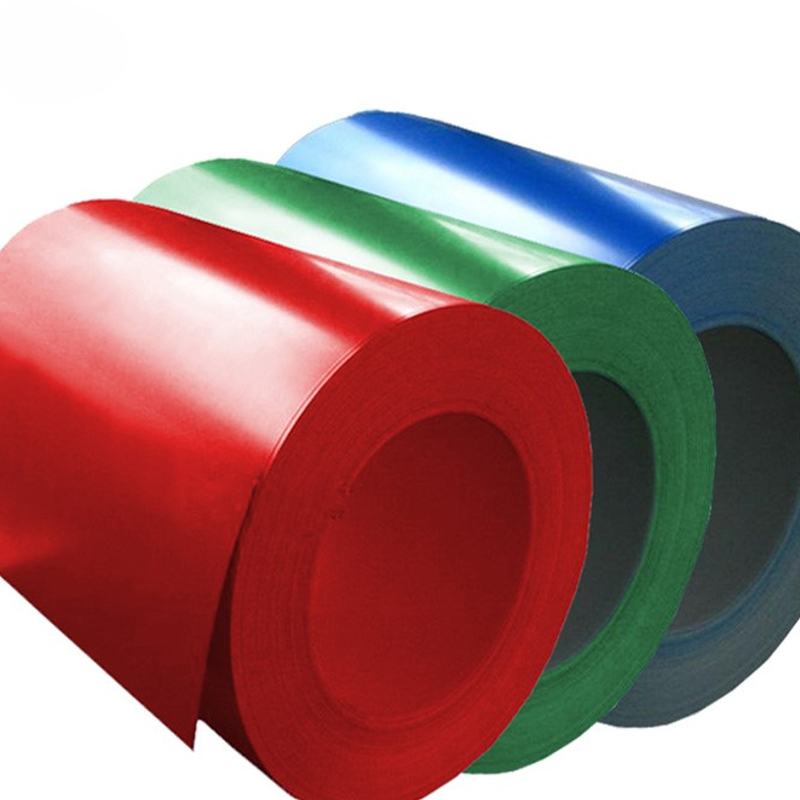

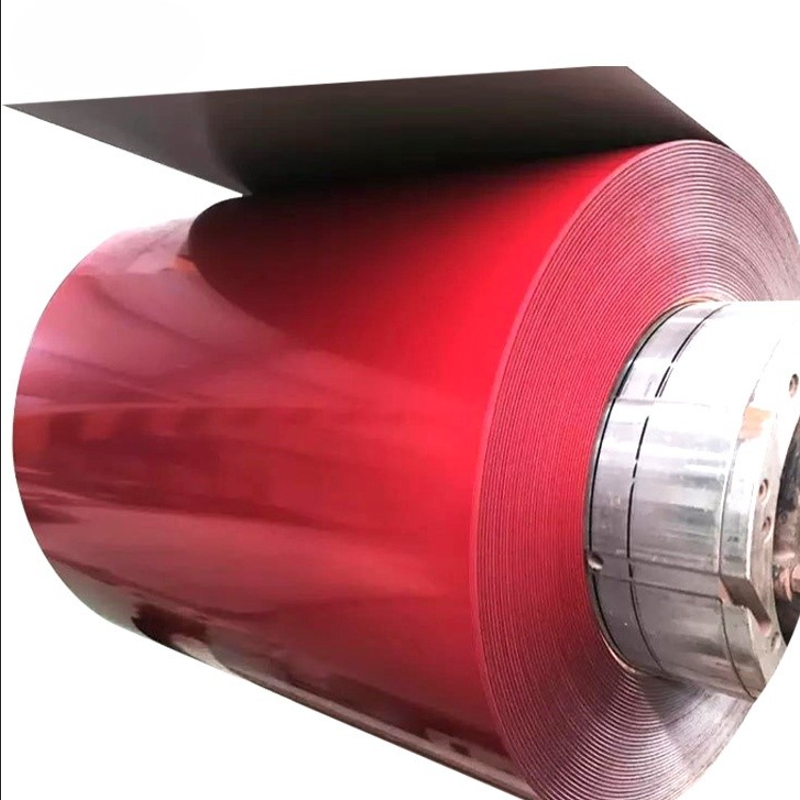

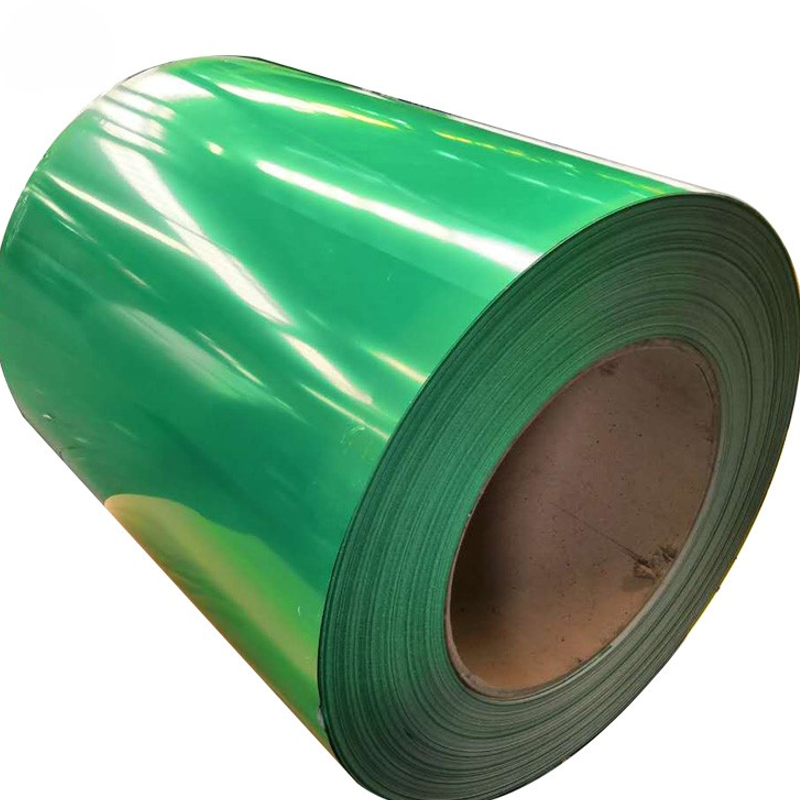

PPGI Coil

- Standard: JIS/EN/ASTM Standard

- Grade: SGCC/DX51D/S250GD/DX52D/DX53D/S280GD/S320GD/S350GD

- Coating: Z40-Z275 or G40/G60/G90

- Coating Thickness

Primer: PU or Epoxy 5um

Top Coat: 15-20 um

Back Primer: PU or Epoxy

Back Coat: PE or Epoxy 5-12um

- Spangle: Regular spangle / Minimized spangle / Zero spangle

- Size: Thickness: 0.15mm-1.2mm Width: 900mm-1250mm

Description

Product Introduction

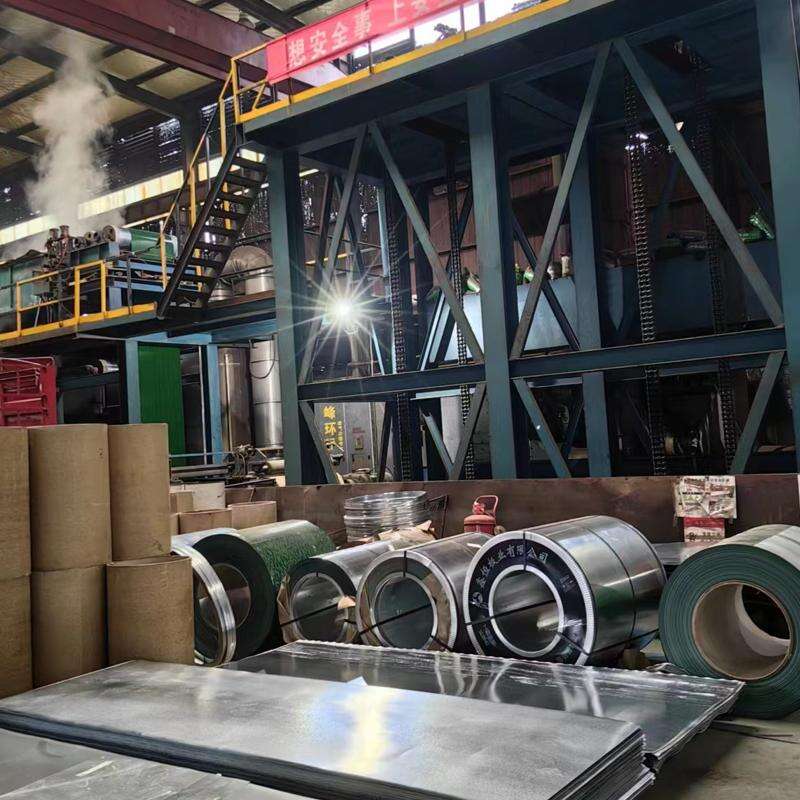

Color coated coil is a product of hot galvanized plate, hot aluminum plated zinc plate, electrogalvanized plate, etc., after surface pretreatment (chemical degreasing and chemical conversion treatment), coated with one or several layers of organic coating on the surface, and then baked and cured. Because coated with a variety of different colors of organic paint color steel coil named, referred to as color coated coil. Color coated coil is a product of hot galvanized plate, hot aluminum plated zinc plate, electrogalvanized plate, etc., after surface pretreatment (chemical degreasing and chemical conversion treatment), coated with one or several layers of organic coating on the surface, and then baked and cured. Because coated with a variety of different colors of organic paint color steel coil named, referred to as color coated coil.

Product Features

1. Light weight: The weight of the color coated roll is relatively light, which can reduce the burden of the building structure and facilitate transportation and installation.

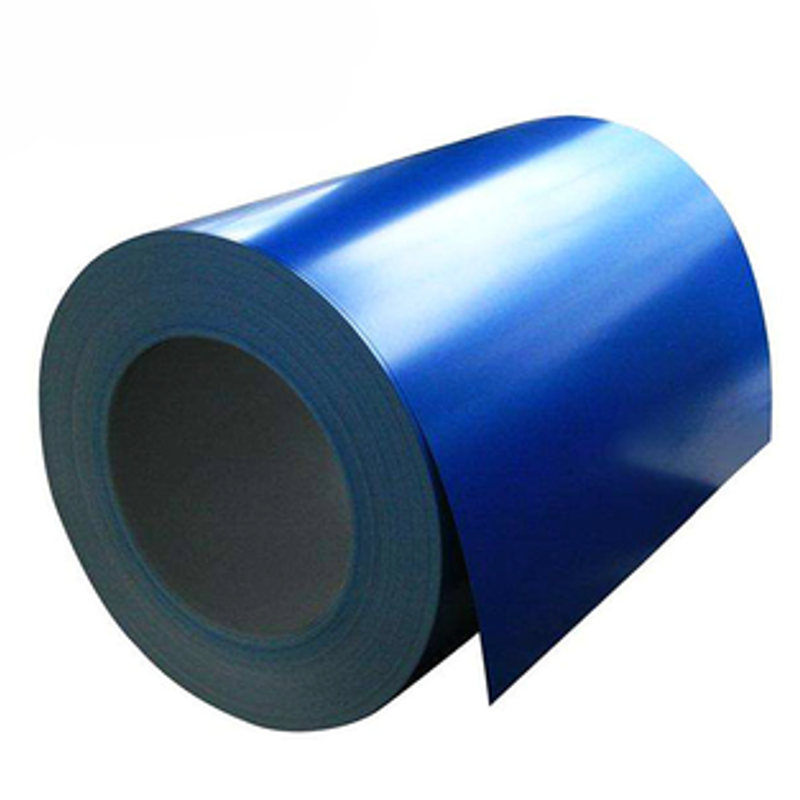

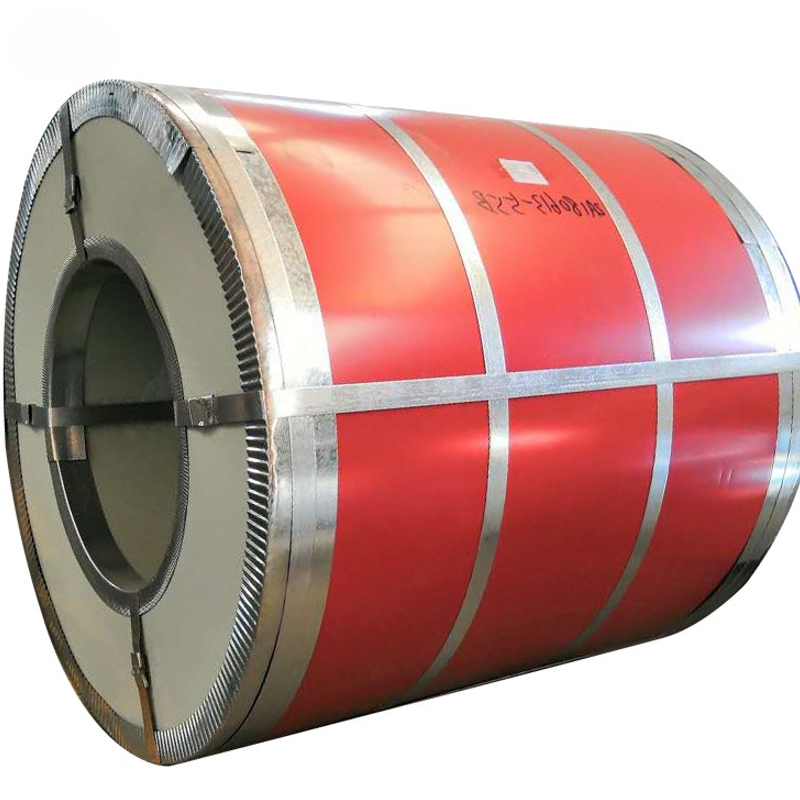

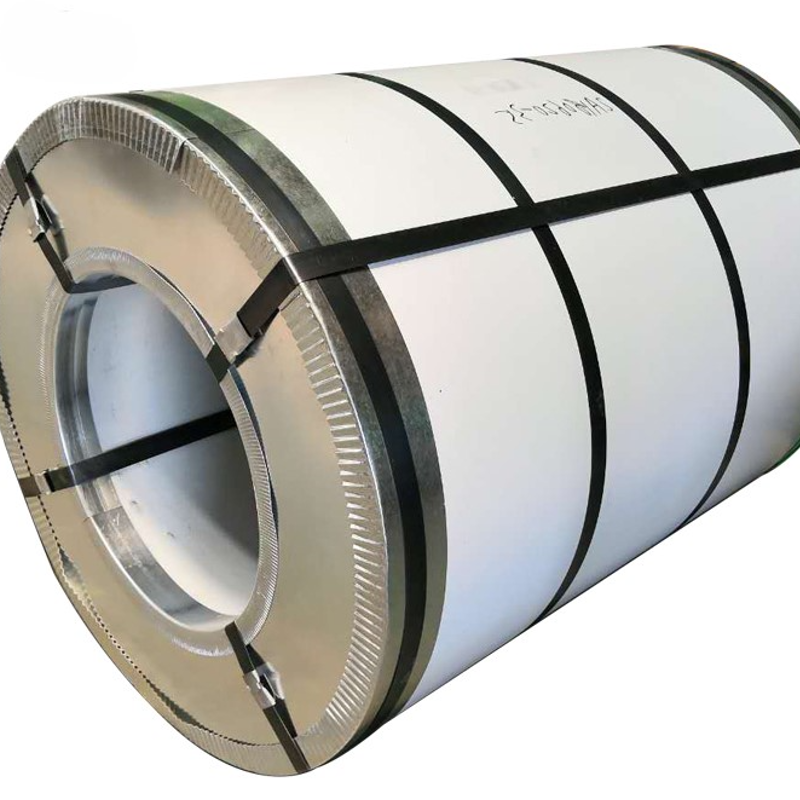

2. Diverse colors: color rolls have a variety of colors and patterns, which can be selected according to the needs of buildings and design requirements to beautify the environment and improve the quality of the effect.

3. Beautiful and generous: The appearance of color coated rolls is beautiful, which can add bright color and texture to the building, making the building more beautiful and generous.

4. Strong corrosion resistance: color coated coil has good corrosion resistance, can resist the erosion of corrosive media such as atmosphere, water vapor, salt spray, and extend its service life.

5. Easy maintenance: The surface of the color coated roll is smooth, not easy to be contaminated with dust and dirt, easy to clean and maintain.

Application Fields

1. Architectural decoration: color coated rolls are widely used in exterior walls, interior walls, roofs, curtain walls and other parts of various buildings, and can be used as architectural decoration materials to improve the beauty and quality of buildings.

2. Furniture manufacturing: color coated rolls can also be used in furniture manufacturing to make a variety of beautiful and generous furniture products, such as bookshelves, wardrobes, cabinets, etc.

3. Electrical manufacturing: Color coated rolls can also be used in electrical manufacturing, such as making air conditioning shells, TV frames, etc.

4. Transportation vehicles: color coated rolls can be applied to transportation vehicles, such as cars, trains, aircraft and other transportation vehicles shell and interior decoration.

5. Building materials: color coated rolls can be used as building materials, such as decorative materials for external walls, interior walls, roofs and other parts of buildings.

Product Parameters

| Pre-painted Galvanized Steel in Coil | Pre-painted 55% AL-Zn coated steel Coil (ColorLume) | |

| Standard | JIS/EN/ASTM Standard | ASTM A755/JIS G3322/EN10169 |

| Grade | SGCC/ DX51D/ S250GD/ DX52D/ DX53D/ S280GD/ S320GD/ S350GD | CS-B/ GR33/ GR37/ GR40/ CGCC/ CGLCC/ DX510/ S220GD/ S250GD/ S280GD |

| Coating | Z40-Z275 or G40/G60/G90 | AZ40--AZ150 |

| Coating Thickness | Primer: PU or Epoxy 5um Top Coat: 15-20 um Back Primer: PU or Epoxy Back Coat: PE or Epoxy 5-12um |

Primer: PU or Epoxy 5um Top Coat: 15-20 um Back Primer: PU or Epoxy Back Coat: PE or Epoxy 5-12um |

| Spangle | Regular spangle / Minimized spangle / Zero spangle | Regular spangle / Minimized spangle |

| Size | Thickness: 0.15mm-1.2mm Width: 900mm-1250mm | Thickness: 0.15mm-1.2mm Width: 900mm-1250mm |

Package