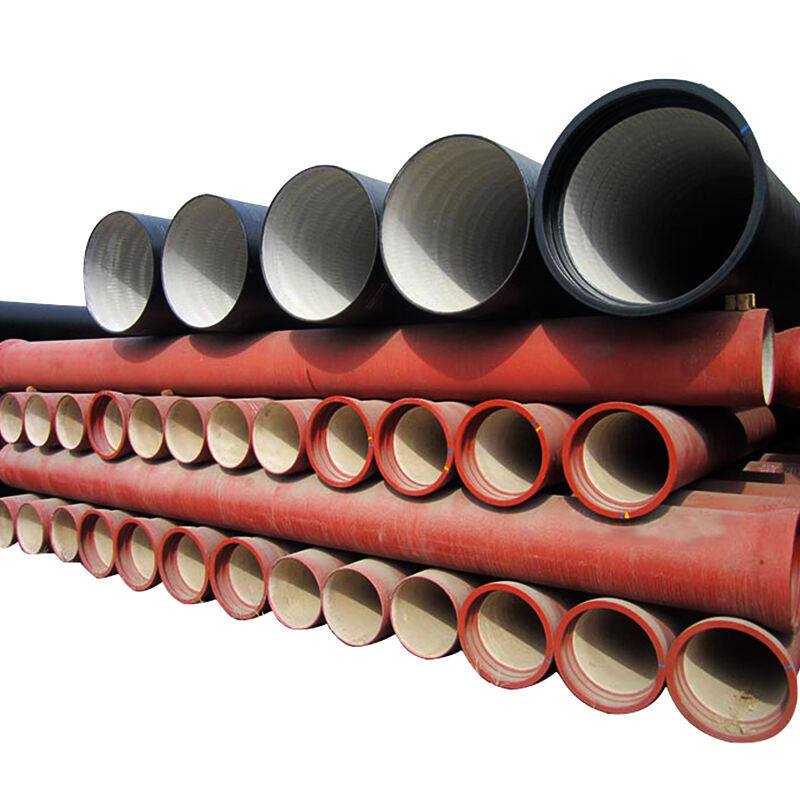

Ductile Iron Pipe

- Standard: ISO2531, EN545, EN598, etc

- Size: DN80~2600mm

- Pressure: PN10, PN16, PN25,PN40

- Class: K12, K9, K8, K7, C25, C30, C40

- Length: 6m, cut to 5.7m

- Application: Water supply project, drainage, sewage, irrigation, water pipeline.

- Certificate: ISO9001, BV, WRAS, BSI

Description

Product Introduction

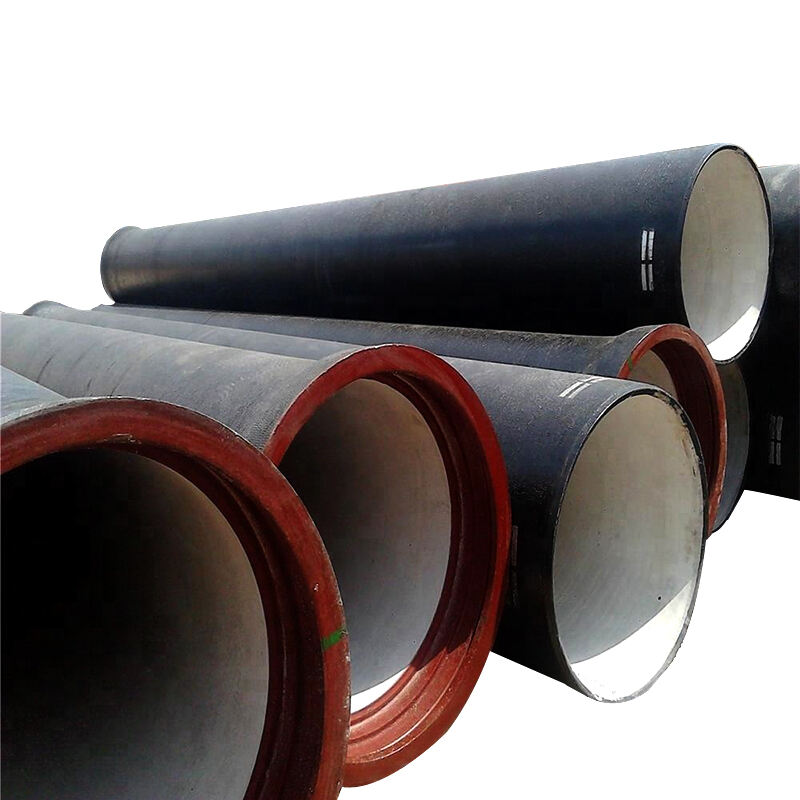

Refers to the pipes made of casting molten iron of No. 18 or above by adding nodularizing agent and then centrifugally cast by centrifugal ductile iron machine at high speed.

It has the essence of iron, the performance of steel, excellent anti-corrosion performance, good ductility and easy installation. It is mainly used for water supply and gas transmission in municipal industrial and mining enterprises.

Product Features

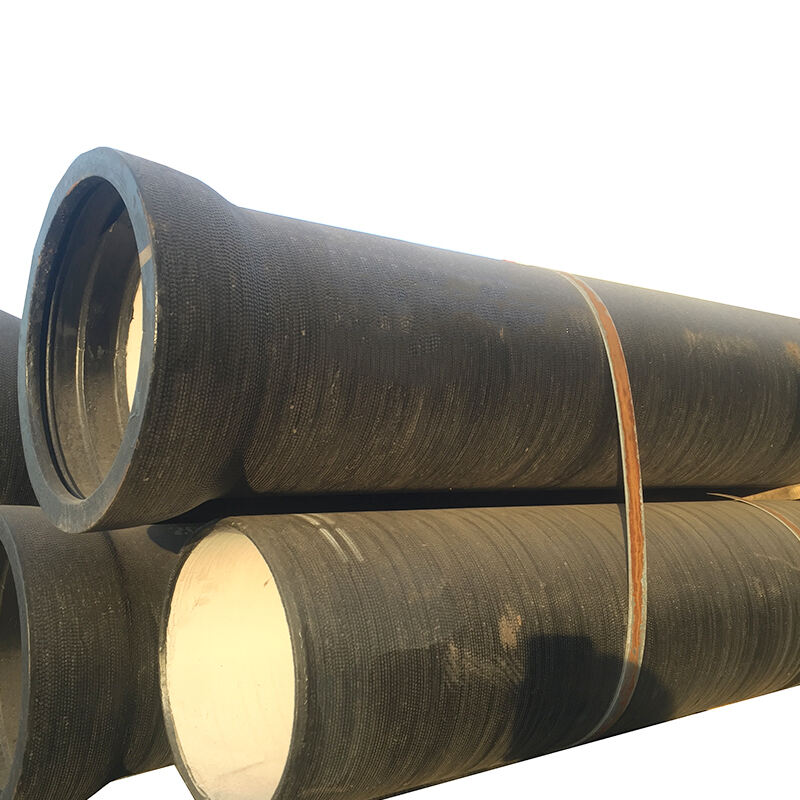

Ductile iron pipe is resilient, safe, and reliable – with a service life of over 100 years. It is an environmentally superior pipe due to its longer service life, resilience, energy savings while in service, recycled content, and its own recyclability. Ductile iron pipe is a key component of a clean energy future and modern, resilient water infrastructure.

- Environmentally superior pipe

Ductile iron pipes are natural, safe, and sustainable. Ductile iron pipes contain at least 90% recycled materials with the pipes themselves being 100% recyclable.

- Better value

Ductile iron pipe is a better value than plastic pipe because it lasts longer and saves money over time. According to a University of Michigan report, Ductile iron pipe is the more cost-effective material over a pipeline’s service life with lower operational and maintenance costs and lower energy costs.

- Lower emissions and less energy

Ductile iron pipe has better environmental performance due to its lower greenhouse gas emissions in both the production and operation phases. From cradle-to-grave, Ductile iron pipe is superior environmentally, as it requires less energy to pump water and has a lower environmental impact.

- Resilient

Ductile iron pipe is resilient through extreme weather events, natural disasters, soil contamination, and unpredictable situations. With its strength and durability, Ductile iron is the pipe of choice to protect against wildfires, earthquakes, floods, hurricanes, extreme temperatures, and the regular, ongoing stresses facing water utility systems.

- Health and safety

Production of Ductile iron pipe does not release dangerous chemicals like vinyl chloride, dioxin or ethylene dichloride. Ductile iron pipe does not absorb toxins like plastic pipe and provides better protection against drinking water contamination. Ductile iron pipe is safer to install and maintain than plastic pipe, which is more prone to catastrophic installation and operational failures causing injuries to workers and damage to property.

- Longer life cycle

Ductile iron pipe requires very little maintenance and has an expected service life of at least 100 years. Ductile iron pipe provides significant cost savings and benefits compared to plastic pipe, which has an average service life of 55 years. A longer life cycle saves money and is better for the environment. It also means fewer interruptions, fewer replacements, and more peace of mind for local communities.

Application Fields

- Water Distribution

- Sewer and Wastewater Applications

- Gas Distribution

- Industrial Applications

- Irrigation

- Mining and Construction

- Fire Protection

Product Parameters

| Standard | ISO2531, EN545, EN598, etc |

| Size | DN80~2600mm |

| Pressure | PN10, PN16, PN25,PN40 |

| Class | K12, K9, K8, K7, C25, C30, C40 |

| Length | 6m, cut to 5.7m |

| Application | Water supply project, drainage, sewage, irrigation, water pipeline. |

| Certificate | ISO9001, BV, WRAS, BSI |

| Internal Coating: | a). Portland cement mortar lining |

| b). Sulphate Resistant cement mortar lining | |

| c). High-Aluminum cement mortar lining | |

| d). Fusion bonded epoxy coating | |

| e). Liquid epoxy painting | |

| f). Black bitumen painting | |

| External Coating: | a). zinc+bitumen(70microns) painting |

| b). Fusion bonded epoxy coating | |

| c). Zinc-aluminum alloy+liquid epoxy painting | |

| Packing: | Bundles, in bulk |

Package