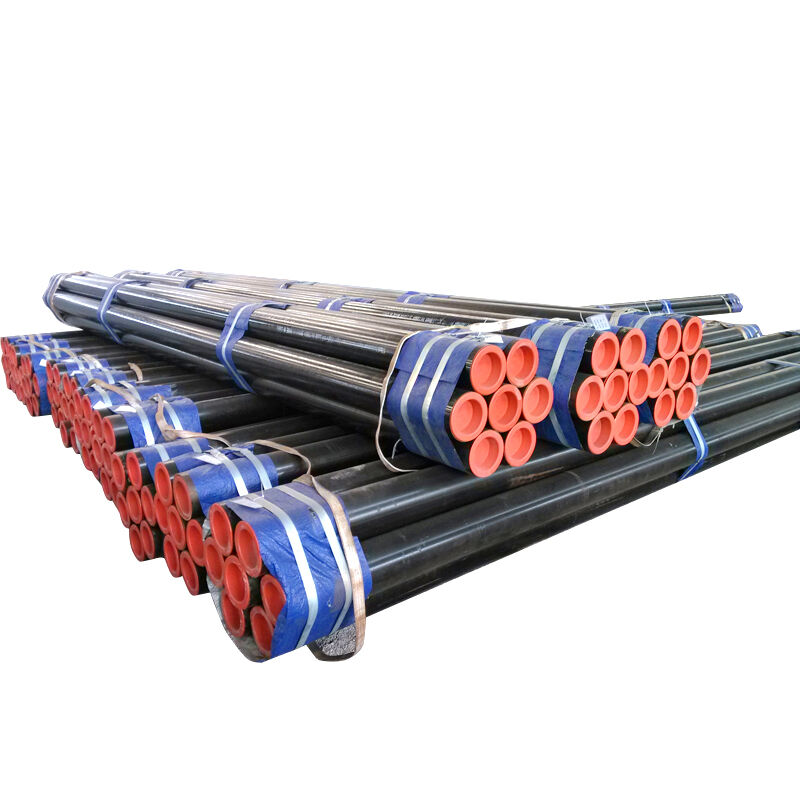

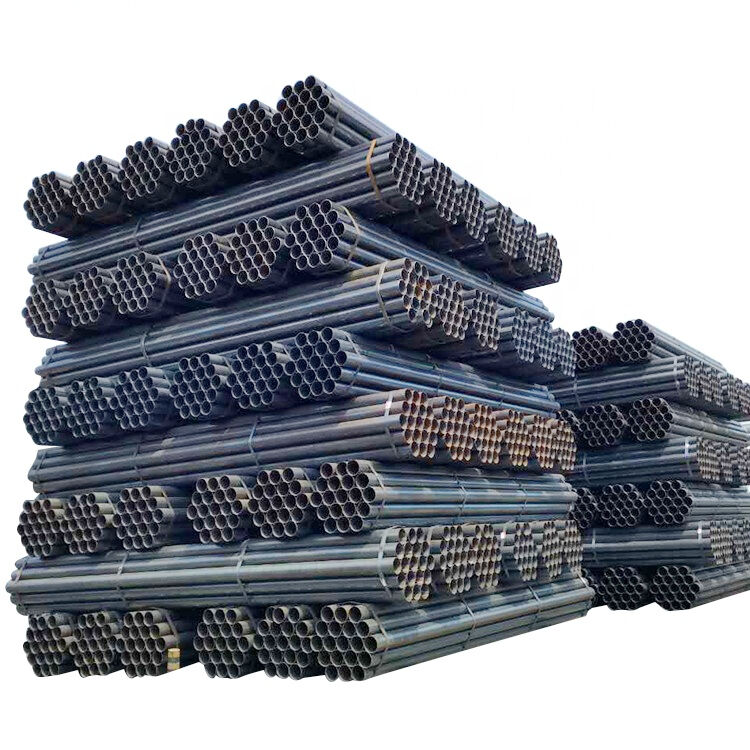

Seamless Steel Pipe

Specification:

Outer diameter (OD): usually ranges from 6mm to 1200mm, common specifications include Φ25mm, Φ89mm, Φ219mm, etc.

Wall thickness (WT): usually ranges from 1mm to 50mm, common wall thicknesses include 3mm, 6mm, 10mm, etc.

Length: usually 6 meters or 12 meters, can also be customized according to customer needs

Description

Product Introduction

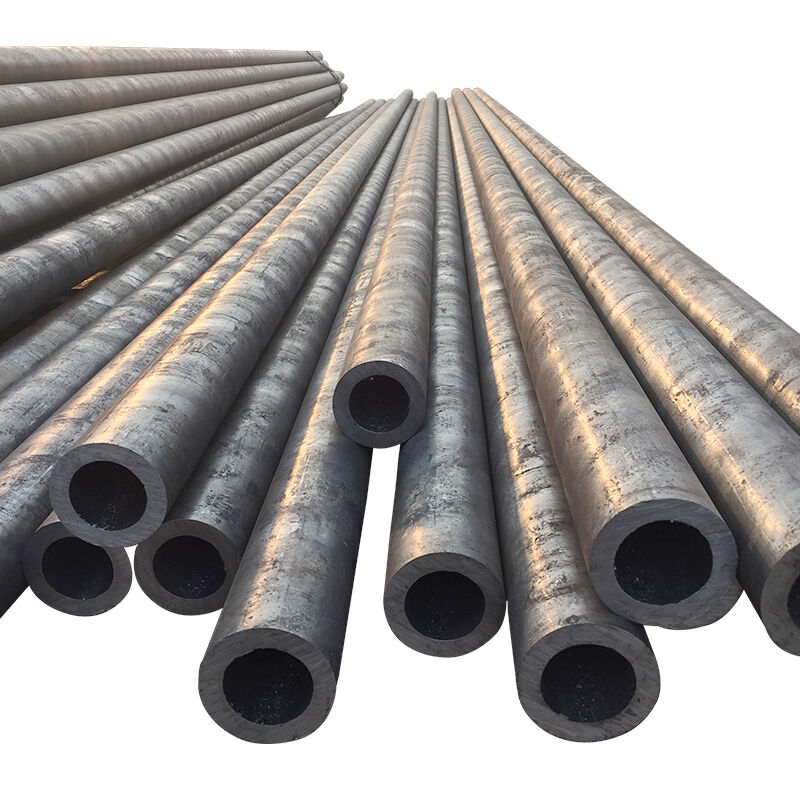

Carbon steel seamless pipe is a seamless steel pipe made of carbon steel as the main material. It is favored for its excellent mechanical properties, seamless structure and wide range of applications. The following is about the main components of carbon steel seamless pipe. The carbon content is usually between 0.06% and 1.5%. According to the carbon content, carbon steel can be divided into low carbon steel, medium carbon steel and high carbon steel. Low carbon steel has good plasticity and weldability, medium carbon steel has high strength, and high carbon steel has higher hardness and wear resistance. In addition, carbon steel seamless pipes may also contain a small amount of manganese, silicon, sulfur, phosphorus and other elements to improve its performance. Carbon steel seamless pipes have high strength, good pressure resistance and temperature resistance, and can withstand working conditions under high pressure and high temperature environments. Carbon steel seamless pipes are manufactured by hot rolling or cold drawing. The hot rolling process heats the steel billet at high temperature and forms a seamless pipe through perforation, rolling and other steps. It is suitable for the production of large diameter and thick wall steel pipes. The cold drawing process is to draw through a die at room temperature to produce small diameter, thin wall seamless pipes with high dimensional accuracy and good surface finish. Both processes can ensure that the steel pipe has a uniform organizational structure and high strength. In addition, the carbon steel seamless pipe can also be further optimized through heat treatment (such as normalizing, annealing, quenching, etc.)

Product Features

1. Seamless structure: Due to the absence of welds, carbon steel seamless pipes have higher safety and reliability under high pressure and high temperature environments.

2.High strength: Carbon steel seamless pipes have high tensile strength and compressive strength, and can withstand greater pressure and load.

3.Good processability: Carbon steel seamless pipes are easy to cut, bend and weld, and can meet the needs of different projects.

4.Corrosion resistance: Through surface treatment (such as galvanizing, painting, etc.), carbon steel seamless pipes can improve their corrosion resistance and are suitable for a variety of environments.

Application Fields

Carbon steel seamless pipes are widely used in industries such as petroleum, natural gas, chemicals, electricity, machinery manufacturing, and construction. Specific applications include:

1.Oil and natural gas transportation: used for oil well pipelines, oil pipelines, and natural gas pipelines.

2.Machinery manufacturing: used to manufacture mechanical parts such as hydraulic cylinders, bearing sleeves, and transmission shafts.

3.Building structures: used for the support and framework of large structures such as bridges and high-rise buildings.

4.Boilers and heat exchangers: used to manufacture high-pressure boiler tubes and heat exchanger tubes.

Product Parameters

|

Material |

The main material of carbon steel seamless pipe is carbon steel |

|

Grade |

Low carbon steel: such as 10# and 20# steel, with good plasticity and weldability |

|

Specification |

Outer diameter (OD): usually ranges from 6mm to 1200mm, common specifications include Φ25mm, Φ89mm, Φ219mm, etc. |

|

Mechanical properties |

Tensile strength (σb): usually 335MPa to 600MPa, the specific value depends on the material and process |

|

Process standards |

GB/T 8162: Seamless steel pipes for structures |

|

Surface treatment |

Black pipe: used directly without surface treatment |

|

Other parameters |

Pressure resistance: Depending on the wall thickness and material, the pressure resistance ranges from a few MPa to tens of MPa. |

Package