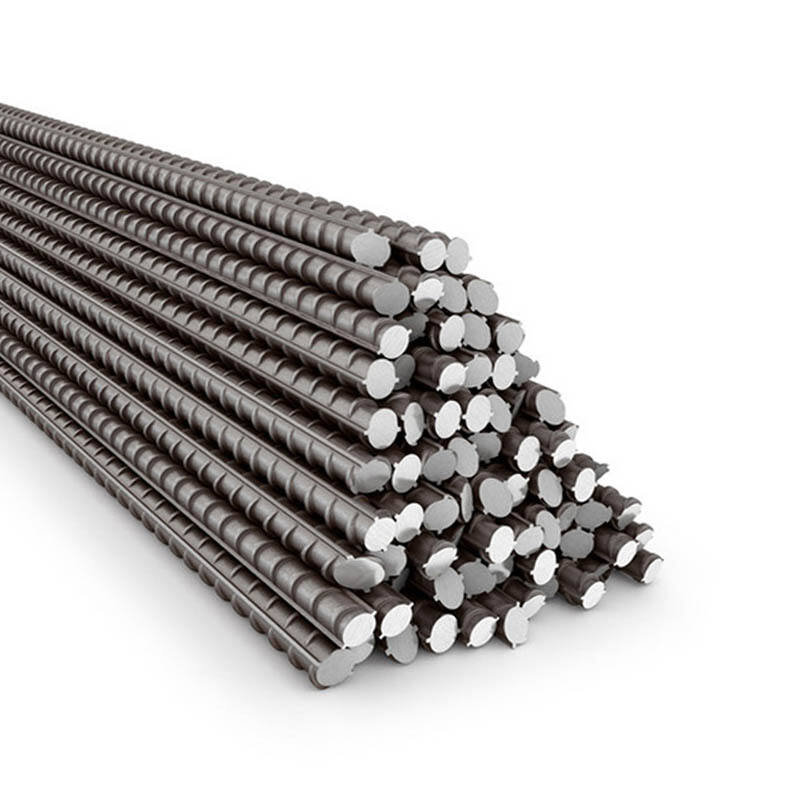

Steel Rebar

- Parameter: Specifications

- Diameter Range: 6mm-50mm (Common specifications: 8mm, 12mm, 16mm, 20mm, 25mm, 32mm)

- Material Standards: GB, ASTM JIS,EN

- Tensile Strength: 400MPa-600MPa

- Yield Strength: 335MPa-540MPa (varies by grade)

- Elongation Rate: ≥14% (HRB400) to ≥16% (HRB500)

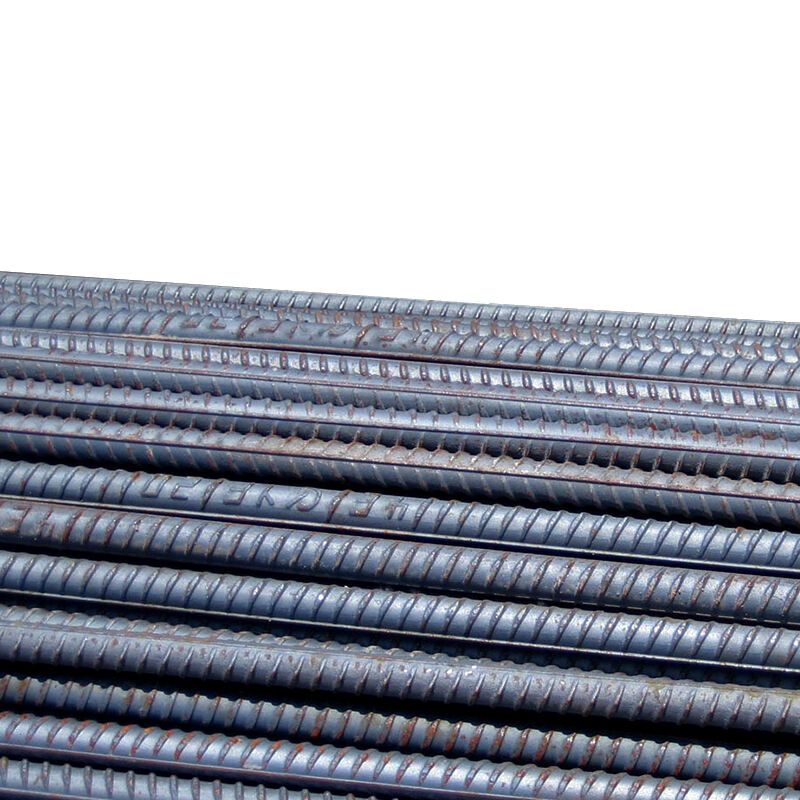

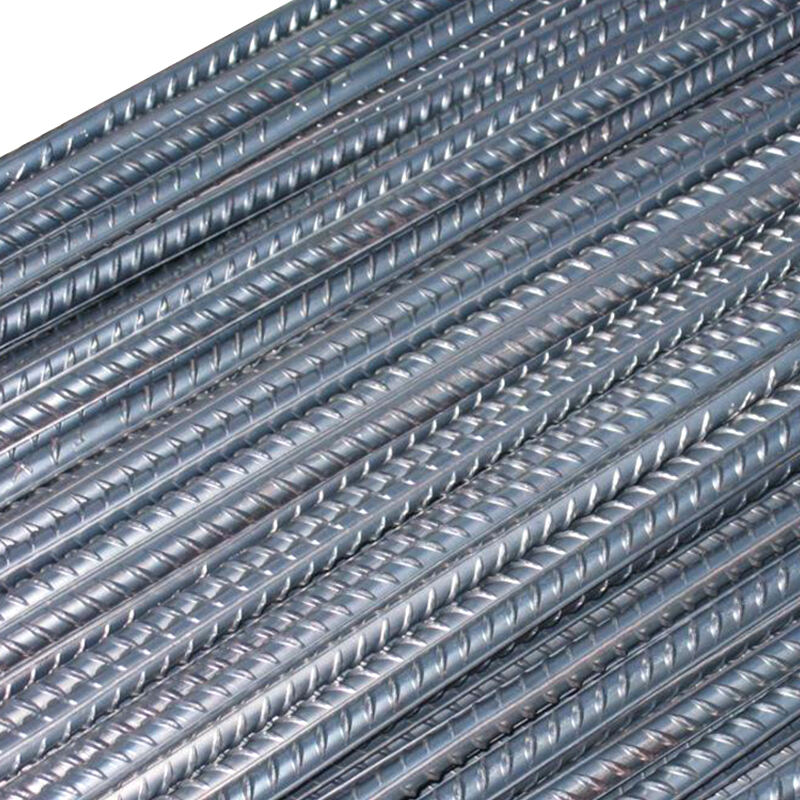

- Surface Profile: Ribbed rebar (HRB, e.g., threaded)

- Length Specifications: 4m,6m, 9m, 12m (customizable lengths available)

- Application Scenarios: Concrete structural beams, columns, slabs, foundations, bridges, etc.

- Place of Origin: Shandong

- Shape: Round Deformed Steel Bar

- Material: HRB335,HRB400,HRB500

Description

Product Introduction

Steel rebar (Rebar) is one of the most fundamental and critical steel products in the construction industry, primarily used to enhance the tensile strength and overall stability of concrete structures. Made from carbon steel or low-alloy steel through hot rolling, cold rolling, or heat treatment processes, it typically features surface threads to improve bonding with concrete. Rebar is categorized into various types based on strength grades, chemical composition, and production methods, and is widely applied in infrastructure projects such as housing construction, bridges, tunnels, and water conservancy projects.

Key Features:

High Strength and Toughness:

Through optimized alloy composition and heat treatment, rebar combines high tensile strength with excellent ductility, effectively resisting dynamic loads (e.g., earthquakes).

Corrosion Resistance:

Select products employ galvanization, epoxy coatings, or weather-resistant alloy elements (e.g., HRB500E) to extend service life.

Superior Bonding Performance:

Ribbed surface design significantly enhances grip with concrete, preventing slippage and cracking.

High Process ability:

Supports secondary processing such as cold bending, welding, and cutting to meet complex engineering requirements.

Eco-Friendliness:

Complies with green building standards, is fully recyclable, and reduces resource waste.

Application Fields

- Building Structures: Load-bearing components in high-rise buildings, residential complexes, and commercial structures, including beams, columns, slabs, and shear walls.

- Infrastructure: Bridge piers and abutments, tunnel linings, highway subgrades, and railway sleepers.

- Hydraulic Engineering: Pressure- and crack-resistant structures such as dams, sluice gates, port terminals, and water pipelines.

- Industrial Use: Reinforcement for factory foundations, equipment bases, and industrial flooring.

- Seismic Engineering: High-ductility seismic rebar (e.g., HRB400E, HRB500E) in earthquake-prone areas to enhance structural safety.

Product Parameters

| Parameter | Specifications |

| Diameter Range | 6mm-50mm (Common specifications: 8mm, 12mm, 16mm, 20mm, 25mm, 32mm) |

| Material Standards | GB , ASTM JIS,EN |

| Tensile Strength | 400MPa-600MPa |

| Yield Strength | 335MPa-540MPa (varies by grade) |

| Elongation Rate | ≥14% (HRB400) to ≥16% (HRB500) |

| Surface Profile | Ribbed rebar (HRB, e.g., threaded) |

| Length Specifications | 4m,6m, 9m, 12m (customizable lengths available) |

| Application Scenarios | Concrete structural beams, columns, slabs, foundations, bridges, etc. |

| Place of Origin | Shandong |

| Shape | Round Deformed Steel Bar |

| Material | HRB335,HRB400,HRB500 |

Packaging & Shipping