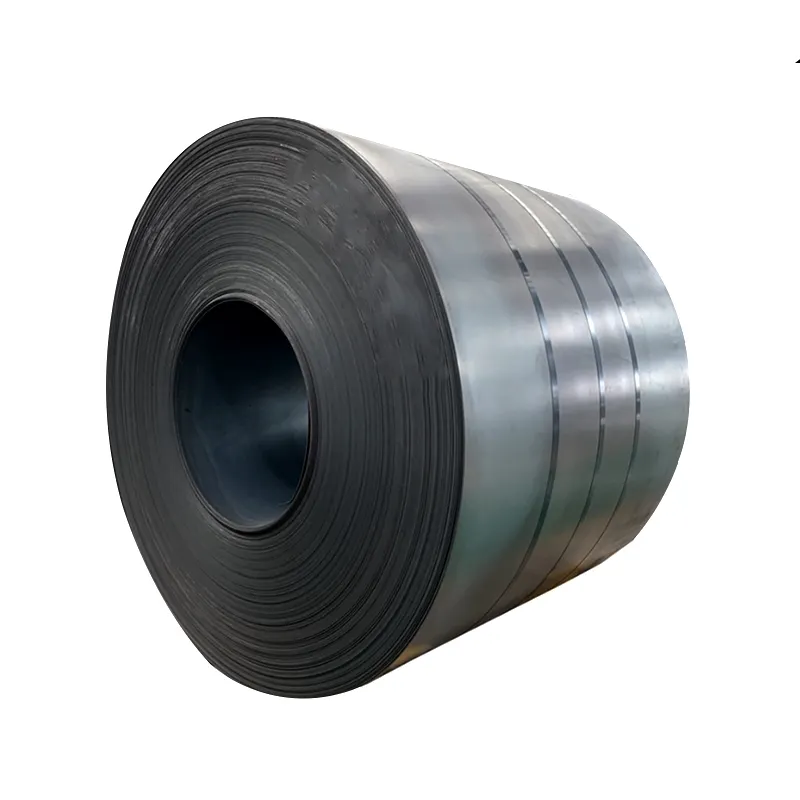

Heavy duty hot rolled steel coil is specifically designed to withstand extreme loads and harsh operating conditions, making it indispensable in numerous industrial applications. Its robust nature and high mechanical strength enable it to support heavy structures and equipment in sectors such as construction, mining, and heavy machinery manufacturing. The term "heavy duty" implies that this type of steel coil has superior performance characteristics compared to standard hot rolled products, often achieved through careful selection of raw materials and advanced manufacturing techniques. The chemical composition of heavy duty hot rolled steel coil typically includes higher levels of carbon and alloying elements like manganese, chromium, and nickel, which contribute to its enhanced strength, hardness, and wear resistance. For instance, in mining equipment, where components are subjected to constant abrasion and impact, heavy duty hot rolled steel coils are used to fabricate parts such as truck frames, conveyor systems, and mining buckets. These applications require the steel to maintain its integrity even under severe stress and abrasive environments. In the construction industry, heavy duty hot rolled steel coils are utilized in the fabrication of large scale infrastructure projects, such as bridges, high rise buildings, and industrial facilities. The steel's ability to bear heavy loads ensures the structural stability and safety of these projects over their lifespan. The manufacturing process of heavy duty hot rolled steel coil involves precise temperature control during the rolling stage to achieve the desired microstructure and mechanical properties. Post rolling heat treatment, such as quenching and tempering, is often applied to further optimize the steel's performance, balancing strength and ductility. Quality assurance for heavy duty hot rolled steel coil is of utmost importance, as any failure in these applications can lead to catastrophic consequences. Extensive testing, including hardness testing, fatigue testing, and fracture toughness evaluation, is conducted to verify the material's compliance with industry standards and customer specifications. With the rise of industrial automation and the need for more efficient equipment, the demand for heavy duty hot rolled steel coil continues to grow. Manufacturers are constantly innovating to develop steel grades that offer higher strength to weight ratios, improved machinability, and better resistance to fatigue and corrosion. Additionally, the integration of advanced simulation technologies allows for more accurate prediction of the steel's behavior under various operating conditions, enabling engineers to design safer and more efficient structures and machines. The heavy duty hot rolled steel coil market is also influenced by global economic trends, with infrastructure development and industrial expansion in emerging markets driving significant growth. As industries strive to increase productivity and reduce maintenance costs, the importance of heavy duty hot rolled steel coil in enabling reliable and long lasting operations cannot be overstated.