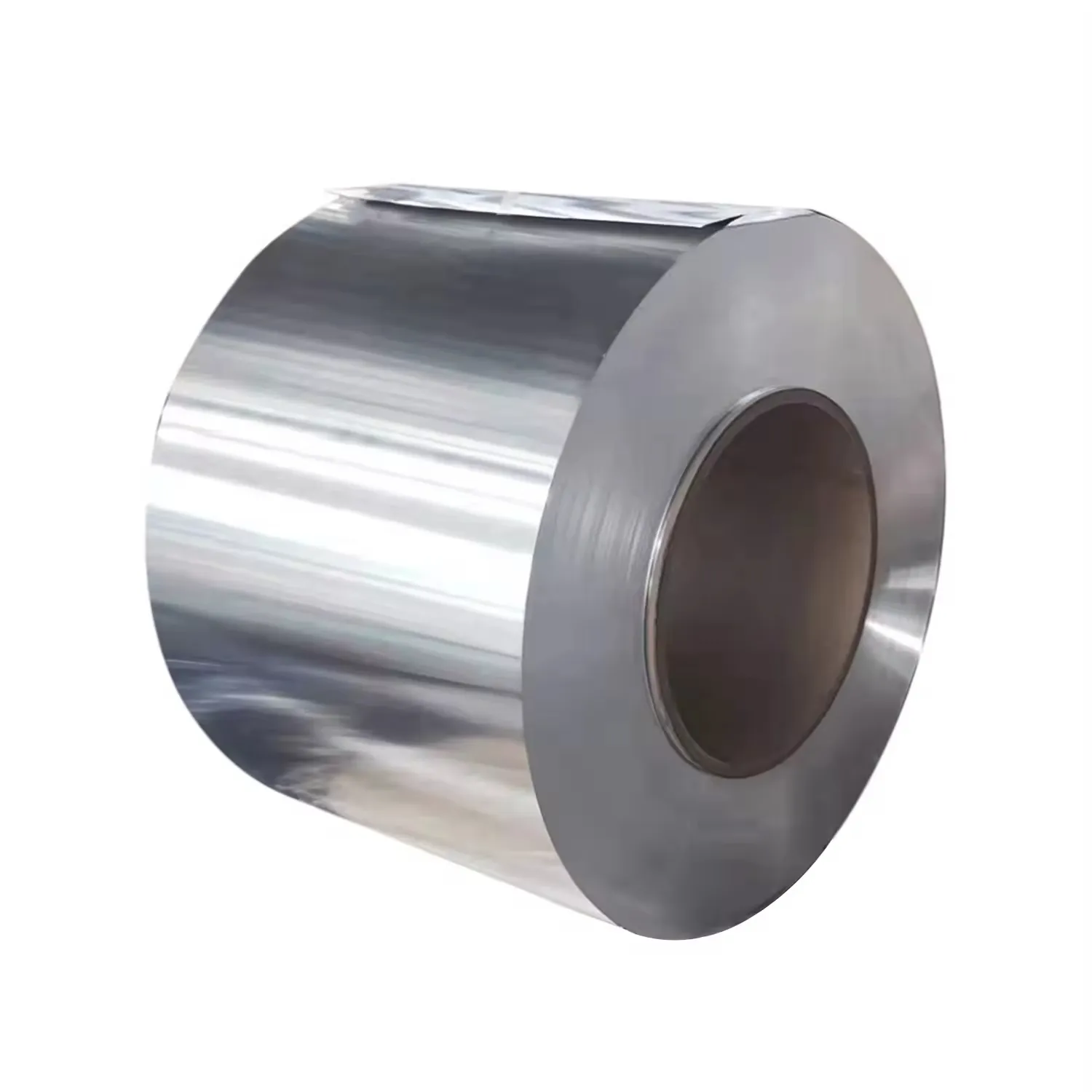

Cold rolled steel coils really boost the strength in all sorts of products from appliances to automotive parts. Let's take a look at what makes cold rolled steel special, how it gets processed, and why different industries rely on it so much. When companies get familiar with these advantages, they can start making smarter choices that actually enhance both how long their products last and how well they perform under stress. Many factories have already seen improvements after switching to cold rolled materials for certain applications.

Characteristics Of Cold Rolled Steel

Cold rolled steel generally has superior surface finish and dimensional accuracy than hot rolled steel does. When steel is rolled at room temperature rather than heated first, it goes through multiple passes in the production line which creates much finer grain structures compared to what happens with hot rolled material. There are also mechanical benefits too since cold rolled steel performs better when subjected to stress or deformation forces. For products where exact measurements matter a lot, manufacturers prefer cold rolling because it allows for much tighter tolerances. This makes cold rolled steel ideal for parts that need precise fits or smooth surfaces in automotive components, appliances, and other manufactured goods.

Manufacturing Process and Its Effects

Cold rolling plays a big role in how good steel coils turn out in the end. The process actually involves several key stages - first comes pickling to strip away those pesky surface oxides, then comes the actual rolling operation, followed by annealing which helps control oxidation levels. Getting each step right matters a lot because manufacturers across different sectors rely on this material. Think about car makers who need consistent sheet metal for body panels, or construction companies requiring reliable structural components. When done properly, cold rolling delivers the kind of quality these industries demand day after day.

Application Over Industries

Cold rolled steel coils play a big role in car manufacturing for making chassis parts and body panels because they combine light weight with good strength that holds up under stress. The same material finds its way into sturdy appliances and furniture as well. Beyond just being functional, this type of steel offers flexibility that lets designers incorporate aesthetic elements too. Manufacturers appreciate how it balances practical needs with visual appeal in their products.

Benefits of Using Cold Rolled Steel

Cold rolled steel stands out because it lasts much longer than other types. When products go through this process, they tend to hold up better against things like scratches, rust spots, and dents from everyday use. For businesses making equipment or parts, this means fewer replacements down the road and lower repair bills over time. The savings can really add up across large manufacturing operations. What many people don't realize is how good cold rolled steel looks too. Its surface comes out nice and smooth without those rough patches that hot rolled versions often have. This makes it ideal for visible components in appliances, automotive parts, or any application where appearance matters as much as strength does.

Industry Developments and Future Projections

As industries keep expanding across the globe, we're seeing a steady rise in need for cold rolled steel products. New manufacturing techniques and better steel treatment methods are already starting to improve material properties, making steel stronger while using less raw resources. Sustainability efforts are also changing how steel gets handled throughout its lifecycle. More companies are finding ways to recycle scrap metal and repurpose old steel components, something that fits right into the growing circular economy framework. For manufacturers willing to adapt their operations now, there's definitely opportunity in meeting what looks to be a long-term shift in material demands, though they'll need to navigate some tricky supply chain issues along the way.

To sum up, various industries benefit greatly from using cold rolled steel coils as they enhance product durability. Through understanding their characteristics, processes along with applications, manufacturers can exploit the benefits of cold rolled steels to develop high quality products designed for modern consumer needs.