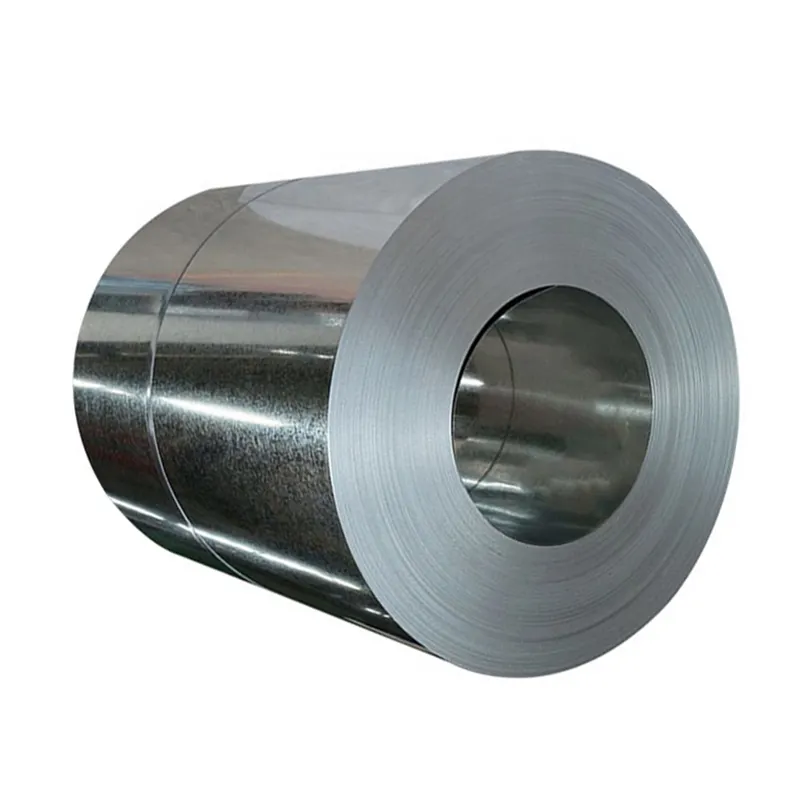

Carbon steel coil custom size services cater to unique project requirements, providing tailored solutions for non standard dimensions and specialized applications. Customization begins with a detailed assessment of client needs, including specific thicknesses (0.5mm to 100mm), widths (500mm to 3,000mm), and coil weights. Manufacturers use advanced slitting and cutting equipment to precision process standard coils into custom sizes, ensuring dimensional accuracy and surface quality. Material selection includes various carbon steel grades, from low carbon for formability to high strength for structural loads, with optional alloying elements to meet performance requirements. Custom sized coils are ideal for niche applications such as specialized machinery components, architectural features, or unique industrial equipment where standard sizes are insufficient. Value added services may include edge conditioning, surface treatment (galvanizing, painting), and pre punching for holes or slots. Quality control ensures that custom coils meet the same mechanical property standards as standard products, with comprehensive testing with mill certificates provided. The ability to produce custom sized carbon steel coils allows engineers to optimize designs for functionality and cost, reducing material waste and fabrication time. This flexibility is crucial for innovative projects across industries, from aerospace to renewable energy, where non standard components are essential.