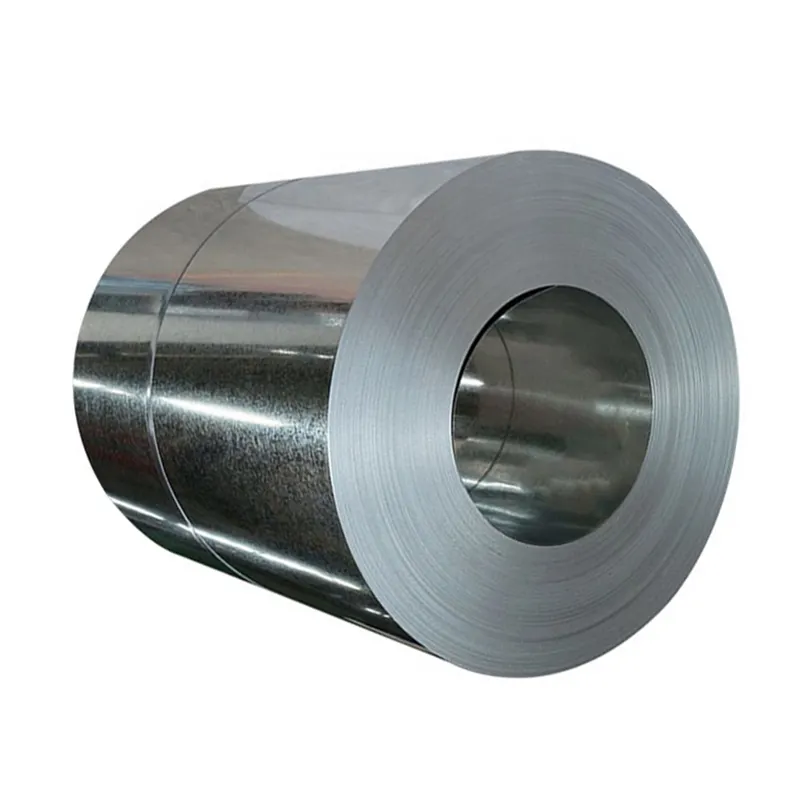

A carbon steel coil manufacturer is a specialized entity responsible for producing carbon steel coils through integrated manufacturing processes, combining material science expertise with advanced production technology. Modern manufacturers operate facilities equipped with melting furnaces (basic oxygen/electric arc), continuous casting machines, rolling mills, and heat treatment lines. The production process begins with raw material selection (iron ore, scrap steel, alloys), melted and refined to precise chemical compositions. Molten steel is cast into slabs, hot rolled at high temperatures to reduce thickness, and cold rolled for precision (if required). Heat treatment processes like annealing, normalizing, or quenching tempering optimize mechanical properties (tensile strength, yield strength, elongation). Manufacturers adhere to international standards (ASTM, EN, JIS) and implement strict quality control, including chemical analysis, ultrasonic testing, and tensile/impact tests. Customization services allow production of coils in specific thicknesses, widths, and grades, with optional surface treatments (galvanizing, painting). Key markets include automotive, construction, energy, and machinery, with leading manufacturers investing in R&D to develop high strength low alloy coils, advanced high strength steels, and sustainable production practices (recycled materials, energy efficient processes). Their expertise in microstructure control and manufacturing efficiency ensures delivery of high performance coils for global industrial applications.