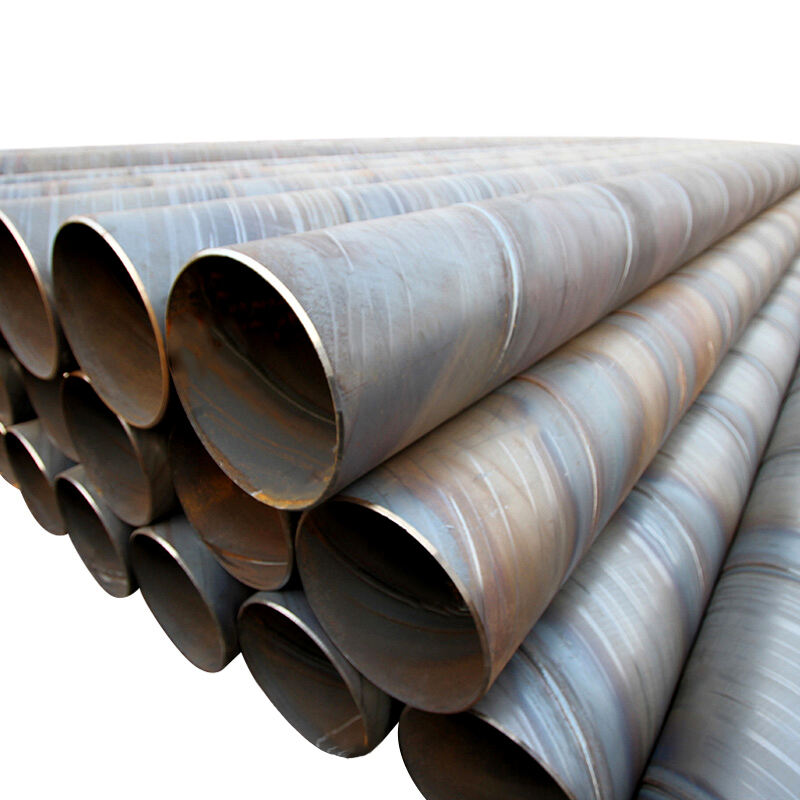

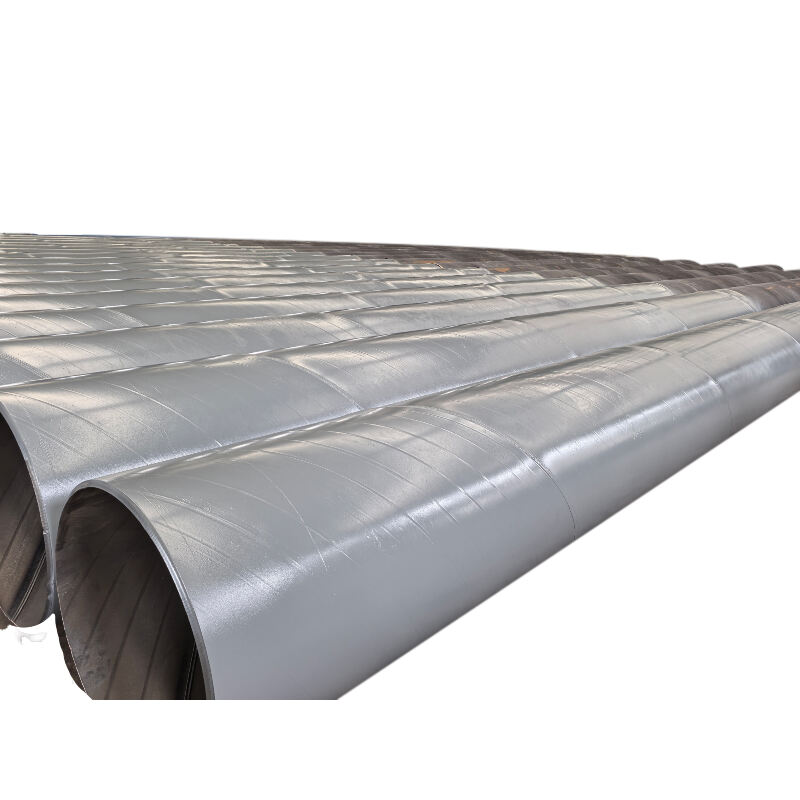

Spiral Weled Pipe

Performance Parameters

- Material: Commonly used materials include carbon steel or low alloy steel such as Q235, Q345, X42, X52, X60, X70, etc. Stainless steel or other special materials can also be used according to needs

- Yield strength (σs): indicates the maximum stress of the material before plastic deformation, the common range is 235MPa to 550MPa

- Tensile strength (σb): indicates the maximum stress of the material before fracture, the common range is 375MPa to 700MPa

- Elongation (δ): indicates the plastic deformation ability of the material, usually required to be ≥20%

- Impact toughness (AKV): indicates the impact resistance of the material at low temperature, usually required to be ≥27J (-20℃)

Description

Product Introduction

Spiral welded pipe is a steel pipe welded by spiral forming process with steel plate or steel strip as raw material. It has the advantages of high strength, large diameter and low cost. It is widely used in oil, gas, water conservancy, construction and other fields. Its flexible specifications and excellent performance make it an important material in the industrial field with broad market prospects. By selecting steel strips that meet the requirements, pre-treatment such as straightening and trimming is performed. The steel strip is rolled into a tube at a spiral angle by a forming machine. The weld is welded by submerged arc welding or high-frequency welding. The weld quality is then ensured by grinding and ultrasonic testing. The welded pipe is then sized and straightened to ensure dimensional accuracy and straightness. Finally, non-destructive testing and anti-corrosion treatment are performed to ensure product quality.

Product Features

1. High strength: The weld of the spiral welded pipe is distributed in a spiral shape, with uniform force and high overall strength.

2. Large diameter: Spiral welded pipes can produce steel pipes with larger diameters, usually ranging from Φ219mm to Φ3000mm, or even larger.

3. Flexible length: The length of the spiral welded pipe can be customized according to demand, usually 6 meters to 18 meters.

4. Low cost: Compared with seamless steel pipes, the production cost of spiral welded pipes is lower and suitable for large-scale use.

5. Strong applicability: Spiral welded pipes can choose materials, wall thickness and surface treatment methods according to different needs.

Application Fields

1.Oil and gas transportation: Pipelines used to transport oil and gas over long distances.

2.Water conservancy projects: used for water pipelines, drainage pipelines, etc.

3.Building structures: used for large building structures such as bridges, docks, and pile foundations.

4.Chemical industry: used to transport chemical media.

5.Heating projects: Pipelines used to transport hot water or steam.

Product Parameters

|

Size parameters |

Outer diameter (OD): The outer diameter of spiral welded pipes ranges from φ219mm to φ3000mm, or even larger. Outer diameter is an important parameter in design and use |

|

Performance Parameters |

Material: Commonly used materials include carbon steel or low alloy steel such as Q235, Q345, X42, X52, X60, X70, etc. Stainless steel or other special materials can also be used according to needs |

|

Process parameters |

Forming speed: The speed of spiral forming of steel strip is usually 10m/min to 30m/min |

|

Quality Standards |

Weld quality: The weld should be free of defects such as cracks, pores, slag inclusions, etc. The weld excess height is usually required to be ≤3mm, and the weld non-destructive testing pass rate should reach 100% |

|

Application Parameters |

Working pressure: The working pressure range of spiral welded pipe is usually 1MPa to 20MPa, depending on the wall thickness and material |

|

Anti-corrosion parameters |

3PE (three-layer polyethylene): 3PE coating thickness is usually 2mm to 4mm |

|

Detection parameters |

Nondestructive testing: Ultrasonic testing (UT): Detect internal defects of welds, Radiographic testing (RT): Detect internal defects of welds, Magnetic particle testing (MT): Detect surface and near-surface defects |

Package