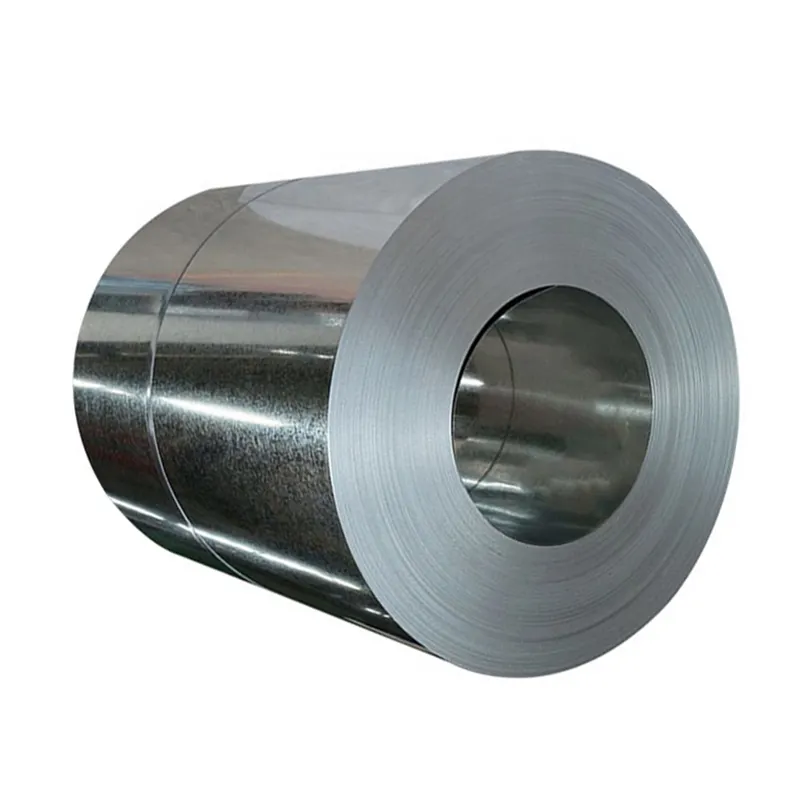

Carbon steel coil for construction is engineered to meet the rigorous demands of structural engineering, providing reliable load bearing capacity and durability for building frameworks, bridges, and infrastructure projects. These coils typically consist of low carbon or medium carbon steel with controlled chemical composition to ensure weldability and formability. Common grades include ASTM A36 (yield strength ≥250 MPa), EN S235 (yield strength ≥235 MPa), and JIS SS400 (tensile strength ≥400 MPa), selected for their balance of strength and workability. Hot rolled coils are commonly used for thicker sections (6mm to 100mm), while cold rolled coils offer precision for thinner structural elements. Mechanical properties such as tensile strength, yield strength, and elongation are optimized to withstand static and dynamic loads, with impact resistance tested at low temperatures for cold climate applications. Surface treatments like galvanizing, epoxy coating, or zinc rich primers are applied to resist atmospheric corrosion, especially for outdoor structures. Construction grade coils are formed into beams, columns, and trusses through processes like bending, rolling, and welding, with dimensional accuracy critical for seamless assembly. Compliance with international standards (ASTM, EN, JIS) ensures material consistency and regulatory approval. As sustainable construction practices gain traction, manufacturers are developing high strength, low alloy coils to reduce material usage and carbon footprints, making them indispensable for modern, eco friendly infrastructure.