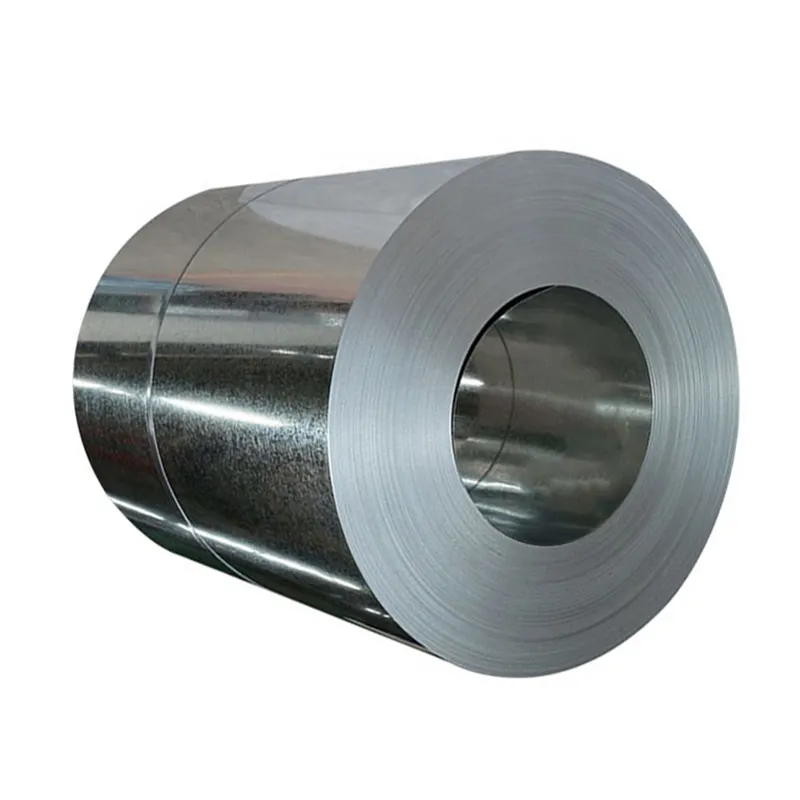

Hot dipped galvanized cold rolled steel coil is a composite material that combines the high precision and smooth surface of cold rolled steel with the excellent corrosion resistance of hot dip galvanizing, offering a versatile solution for various applications. The production process starts with cold rolling the steel to achieve the desired thickness, dimensional accuracy, and surface finish. The cold rolled coil is then subjected to hot dip galvanizing, where it is immersed in a molten zinc bath at high temperature, forming a thick, adherent zinc coating on the surface. The zinc coating typically consists of a zinc iron alloy layer and a pure zinc layer, providing both barrier protection and sacrificial corrosion protection. The thickness of the zinc coating can be controlled, ranging from 60 to 275g/m², depending on the application's corrosion resistance requirements. The hot dip galvanizing process not only enhances corrosion resistance but also improves the paintability and adhesion of subsequent coatings, making it suitable for applications that require both corrosion protection and aesthetic appeal. Hot dipped galvanized cold rolled steel coils have excellent mechanical properties, combining the strength and hardness of cold rolled steel with the ductility and formability needed for various processing operations such as stamping, bending, and rolling. They are widely used in the construction industry for roofing, wall cladding, and structural components, where corrosion resistance and durability are essential. In the automotive industry, they are used for underbody components, chassis parts, and exterior panels, providing protection against road salt and other corrosive agents. The home appliance industry utilizes them for refrigerator cabinets, washing machine drums, and air conditioner frames, ensuring long term performance and a good surface for painting or coating. The performance of hot dipped galvanized cold rolled steel coils is evaluated through various tests, including salt spray tests, bend tests, and adhesion tests, to ensure the integrity of the zinc coating and the mechanical properties of the substrate. With the growing awareness of the importance of corrosion resistance in infrastructure and manufacturing, hot dipped galvanized cold rolled steel coils have become an indispensable material in many industries, offering a cost effective balance between performance and durability.