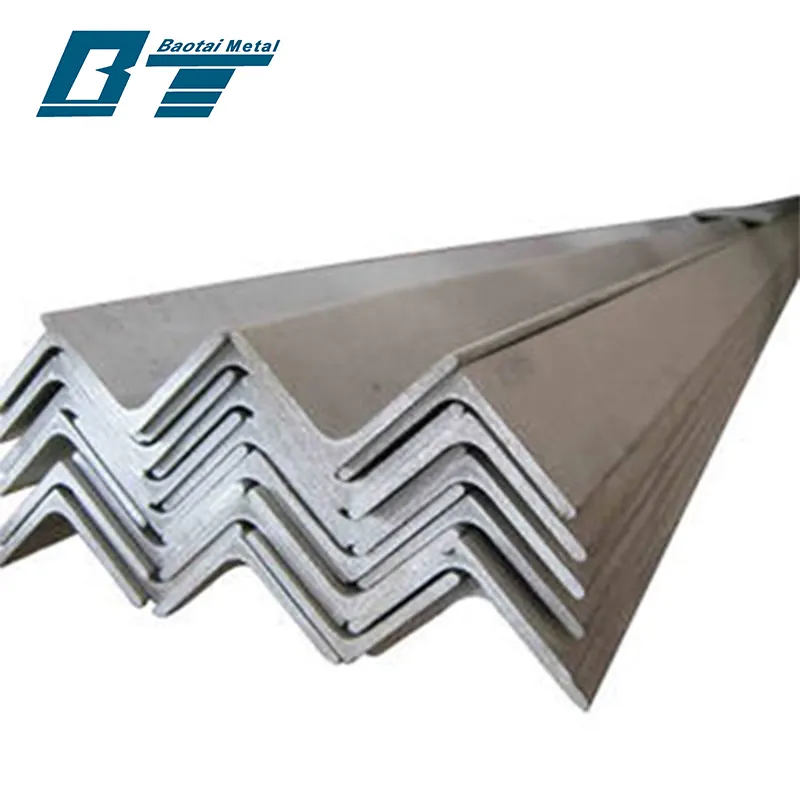

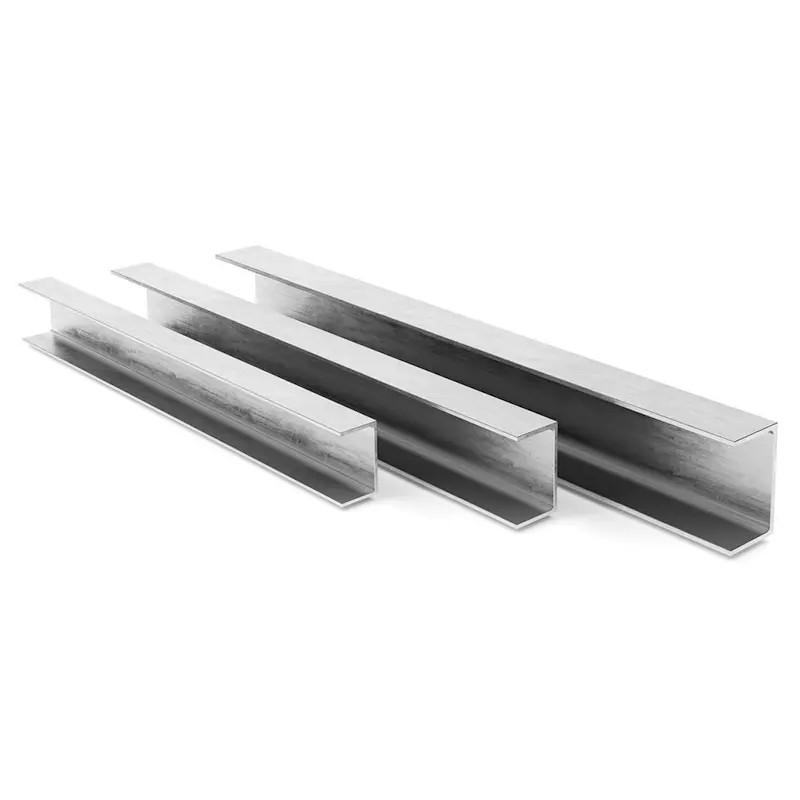

Angle bar for building applications serves as a versatile structural element in residential, commercial, and industrial constructions, valued for its cost effectiveness and ease of installation. Predominantly made from hot rolled carbon steel (grades like ASTM A36 or EN S235), these bars feature leg lengths from 25mm to 200mm and thicknesses 3mm to 25mm, adapted to load requirements. The L shape facilitates use as column braces, beam connectors, and truss members, distributing compressive and tensile forces efficiently. In residential construction, they reinforce door and window frames, support roof trusses, and form lightweight partition frameworks. For commercial buildings, angle bars contribute to curtain wall supports, mezzanine structures, and equipment mounting brackets. Industrial facilities utilize them in conveyor systems, storage racks, and structural supports for heavy machinery. Surface protection via galvanizing or powder coating is common for outdoor applications, while primed finishes suit interior use. Fabrication shops often pre cut and pre drill angle bars to project specifications, reducing on site labor. Compliance with building codes (e.g., IBC, Eurocode 3) ensures structural safety, with engineers selecting grades based on seismic zones, wind loads, and environmental exposure. The modular nature of angle bars enables flexible design adjustments, making them indispensable in both traditional and modern construction methodologies.