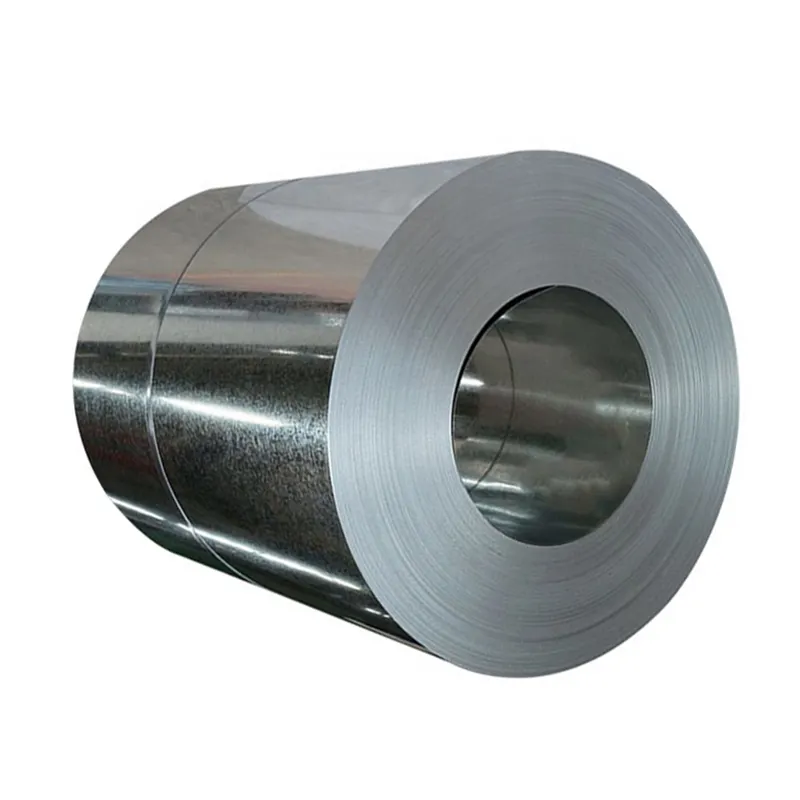

A 0.5mm thickness in galvanized steel coils represents a versatile gauge suitable for lightweight yet durable applications. This thickness, often referred to as 18 gauge in imperial units, balances formability with structural integrity for products like ventilation ducts, electrical enclosures, and domestic appliances . The thin gauge requires precise control during hot dip galvanization to ensure uniform coating adhesion without excessive zinc build up, which could affect subsequent forming operations. ASTM A653 specifies minimum coating weights for 0.5mm coils, with Z275 (275g/m²) providing optimal corrosion protection for indoor outdoor use. Mechanical properties are critical—yield strength should be ≤280 MPa to allow deep drawing without springback, while tensile strength ≥350 MPa ensures durability . Quality control includes eddy current testing for coating thickness and bend tests to verify ductility (180° bend without cracking). In construction, 0.5mm galvanized coils are used for light gauge steel framing, where their high strength to weight ratio reduces material costs. Recent innovations in nano composite coatings have enhanced scratch resistance for this thickness, extending service life in high abrasion environments.