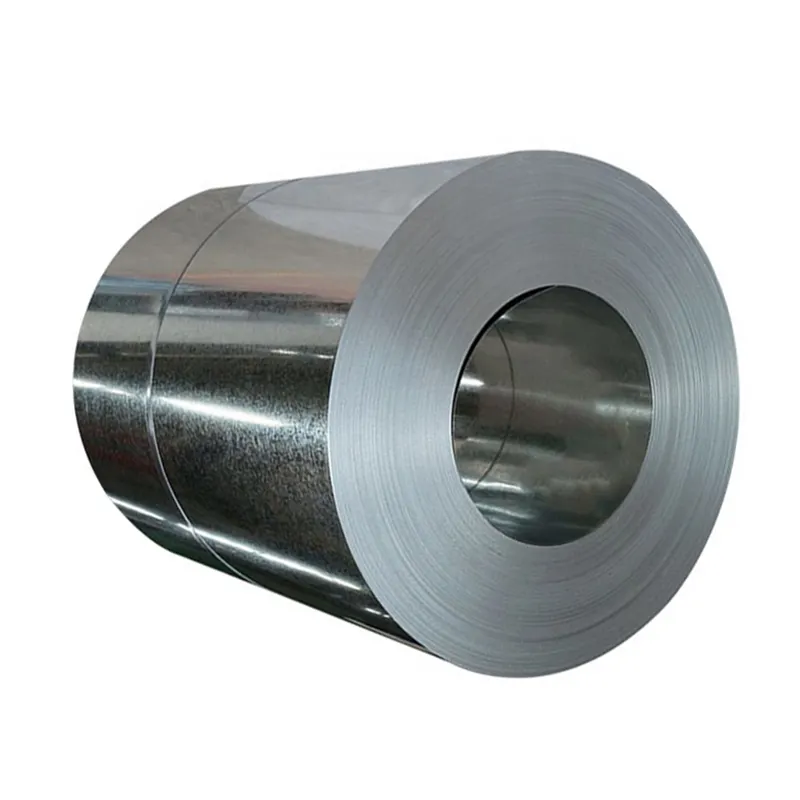

Galvanized steel coils are indispensable in the construction industry, valued for their corrosion resistance, formability, and cost effectiveness. Applications span roofing (standing seam and corrugated profiles), wall cladding, structural framing, and drainage systems. Construction grade coils typically feature Z275 zinc coatings (275g/m²) to withstand weathering, with thicknesses ranging from 0.3mm (light gauge) to 3.0mm (structural) . Key standards include ASTM A653 (U.S.) and EN 10143 (Europe), which specify mechanical properties like yield strength (220 350 MPa) and elongation (>15%) for formability . Fabrication methods include roll forming for panels, punching for fastener holes, and bending for architectural details. In sustainable construction, galvanized steel's high recyclability (90+%) and long service life (20+ years) align with green building standards. Recent trends include energy efficient coatings that reflect solar radiation, reducing cooling loads in buildings, and pre painted galvanized coils that eliminate on site painting. Corrosion protection is enhanced in coastal areas with higher zinc coatings (Z350) or alloyed layers (Zn Al Mg).