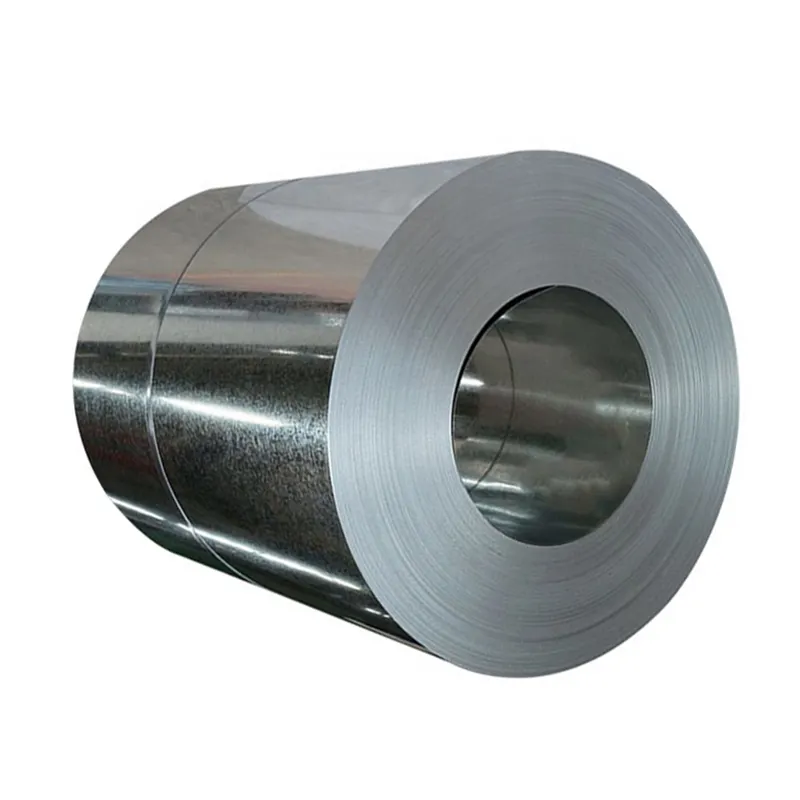

Galvanized steel coils with Z275 zinc coating are defined by their 275g/m² zinc layer, a standard specified in ASTM A653/A653M and designed for high corrosion environments . The hot dip galvanization process immerses cold rolled steel coils in molten zinc, forming a metallurgical bond between zinc and iron that creates a protective layer resistant to atmospheric corrosion. The Z275 designation (equivalent to G90 in the U.S. system) ensures a coating thickness sufficient to withstand over 15 years of exposure in moderate climates without significant degradation. Key applications include outdoor roofing, fencing, and industrial equipment where moisture exposure is high. The zinc coating acts through both barrier protection (physical separation from the environment) and cathodic protection (sacrificial corrosion of zinc to protect the steel substrate) . Performance testing includes salt spray exposure (ASTM B117), where Z275 coatings typically exhibit white rust formation after 1,000+ hours. Surface preparation before galvanizing is critical—degreasing and pickling ensure proper zinc adhesion. Recent advancements in alloyed zinc coatings (e.g., Zn Al) enhance corrosion resistance further, though Z275 remains the cost effective standard for most industrial applications.