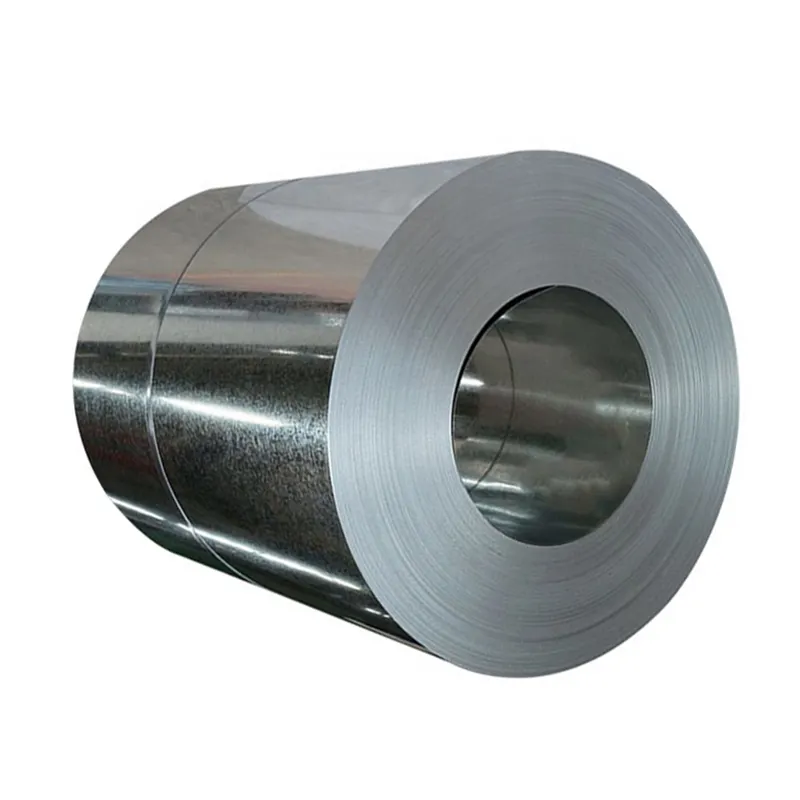

Hot dip galvanized steel coil manufacturers specialize in producing corrosion resistant steel through a precise metallurgical process. The production line typically includes pickling (to remove mill scale), fluxing (to promote zinc adhesion), and immersion in a molten zinc bath (450 460°C) to form a protective intermetallic layer . Key technological considerations include bath temperature control (±5°C) to prevent excessive iron zinc alloy formation, which could brittleness, and air knife adjustment to regulate coating thickness (e.g., Z275). Quality manufacturers implement continuous annealing to optimize steel ductility before galvanizing, ensuring formability for downstream processes. Certifications like ISO 9001 and compliance with ASTM A653 or EN 10143 are essential for market credibility. Global manufacturers often operate multiple lines to handle coil widths up to 1,850mm and weights up to 30 tons, with in line inspection systems (laser gauges for thickness, X ray for coating weight) ensuring consistency. Environmental considerations drive investments in fume extraction systems and zinc slag recycling. Recent innovations include automated coil handling to reduce surface damage and smart manufacturing systems that monitor process parameters in real time for predictive maintenance.