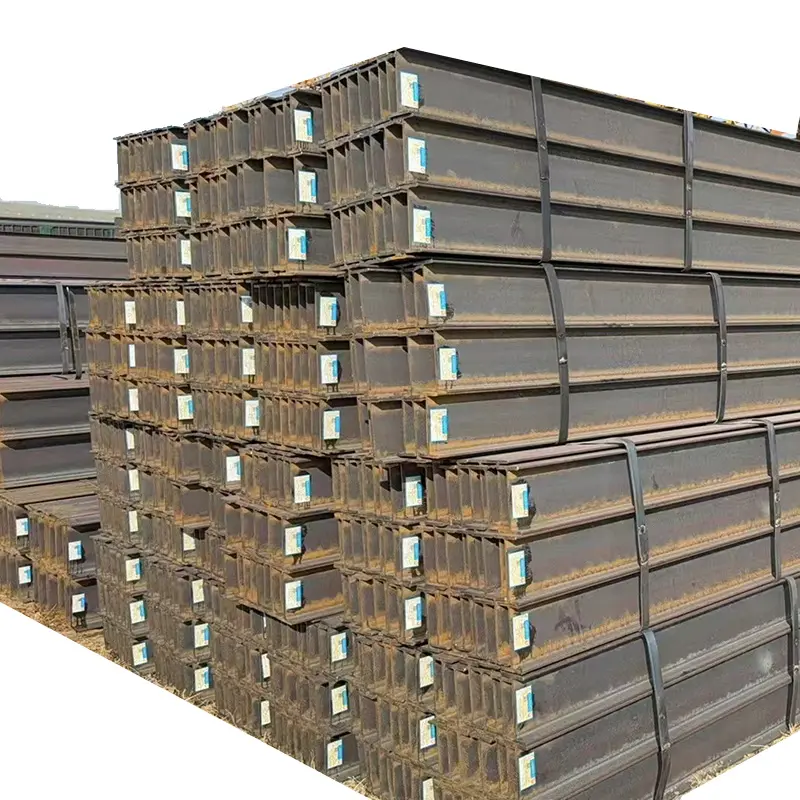

High strength H beams, defined by yield strengths exceeding 400 MPa (e.g., S460, A572 Grade 65), cater to demanding applications where weight reduction and high load capacity are critical. These beams leverage advanced metallurgy, often incorporating microalloying elements like niobium or vanadium to enhance strength without sacrificing ductility . Key applications include long span bridges, heavy industrial machinery, and seismic resistant structures. Design advantages include reduced beam sizes (up to 30% smaller sections compared to standard grades) and lower foundation costs due to reduced dead loads. Fabrication challenges include stricter welding procedures (preheating and controlled cooling to prevent hydrogen induced cracking) and precision cutting to maintain dimensional tolerances. Quality assurance involves ultrasonic testing for internal defects and tensile testing to verify mechanical properties. In offshore platforms, high strength H beams with corrosion resistant coatings withstand harsh marine environments, while in renewable energy, they support wind turbine foundations under cyclic loading. Recent developments in quenched and tempered (Q&T) steels have pushed yield strengths to 690 MPa, enabling unprecedented structural spans.