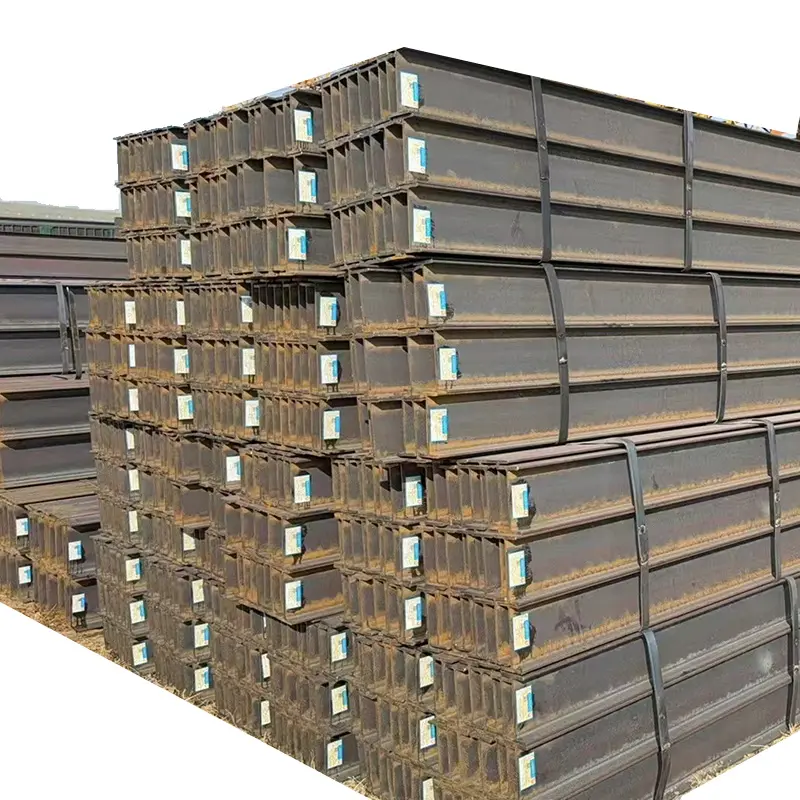

Custom fabrication of H beams involves precision engineering to meet project specific structural requirements, integrating material science with manufacturing expertise. The process begins with selecting appropriate steel grades, such as S355 for high strength applications or A36 for general construction, followed by detailed CAD modeling to define dimensions (height, flange width, web thickness) and fabrication specifications . Key fabrication techniques include hot rolling for large sections, cold forming for precise tolerances, and welding for complex assemblies. Quality control is critical, with non destructive testing (UT/MT) ensuring weld integrity and dimensional checks adhering to standards like ASTM or EN. Customizations may involve punching holes for bolt connections, cambering for bridge spans, or fire resistant coatings. Fabricators must also consider transportation constraints, often segmenting large beams for on site assembly. Case studies in high rise construction show that pre fabricated H beam modules can reduce on site labor by 30%, while bridge projects require strict compliance with load bearing calculations to withstand dynamic forces. Collaboration with structural engineers is essential to optimize weight to strength ratios, especially in seismic zones where ductility is prioritized over pure strength.