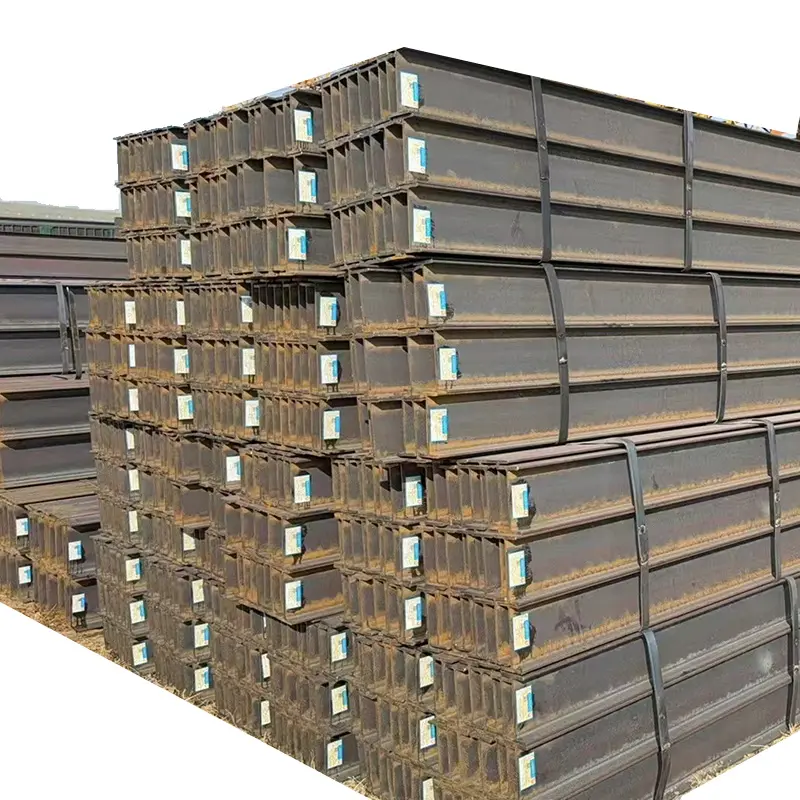

As a fundamental construction material, H beams (wide flange beams) offer unmatched versatility in structural engineering. Their cross sectional geometry provides high second moment of area, making them ideal for resisting bending and torsional forces in buildings, bridges, and industrial facilities . Common steel grades range from S235 (yield strength 235 MPa) for low rise structures to S355 (355 MPa) for heavy duty applications, with specifications adhering to regional standards (ASTM, BS, DIN). H beam selection involves calculating required section modulus based on dead loads (structure's own weight), live loads (occupancy/equipment), and environmental loads (wind/snow). In high rise construction, composite systems pair H beams with concrete slabs to enhance fire resistance and reduce floor depths. For industrial sheds, lightweight H beams with open web sections optimize span to weight ratios. Fabrication flexibility allows for on site modifications, though pre fabrication in controlled environments ensures higher quality. Sustainability is increasingly important, with recycled steel content often exceeding 90% and end of life recyclability minimizing waste.