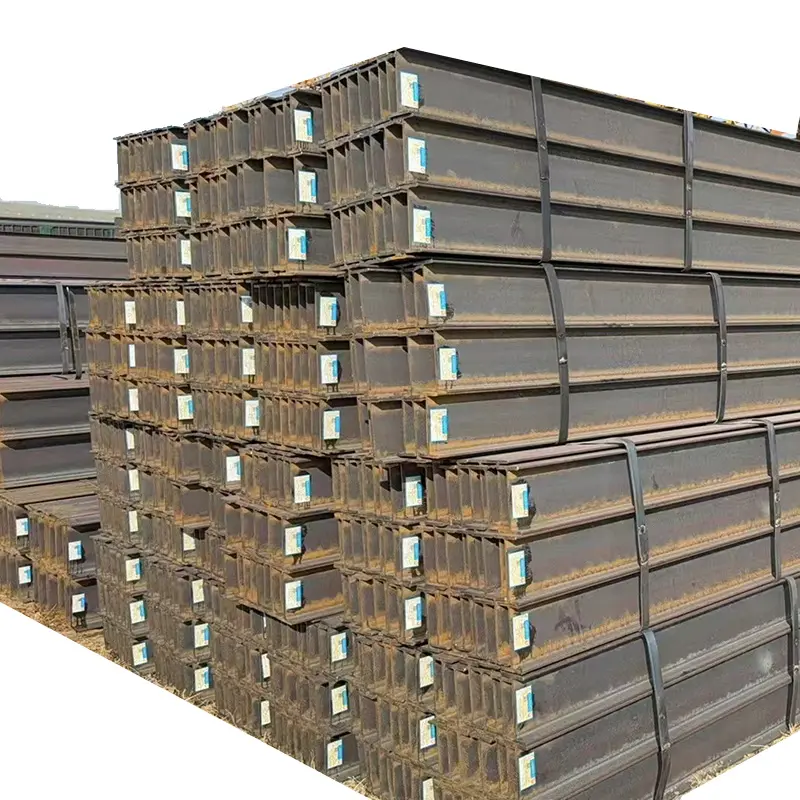

H beams are the backbone of modern bridge construction, valued for their exceptional load bearing capacity and structural efficiency. Bridge specific H beams typically conform to standards like AASHTO in North America or EN 10025 in Europe, with popular grades including A572 Grade 50 and S355J2 . Their "H" shape distributes bending moments effectively, minimizing deflection under traffic loads. Key design considerations include span length (shorter spans use lighter sections like 200x100mm, while long spans may require 630x178mm beams), environmental exposure (galvanized coatings for coastal bridges), and seismic activity (ductile grades for earthquake zones). Fabrication often involves cambering to counteract sagging under permanent loads, with shop welding preferred for precision. Connection details are critical—moment resisting joints use fully welded flanges, while simple supports rely on bolted web connections. Recent innovations include high performance steel (HPS) grades that reduce beam weights by 20% while maintaining strength, and corrosion resistant alloys for longevity in harsh environments. Maintenance considerations, such as accessible coating inspection points, are also integrated during design.