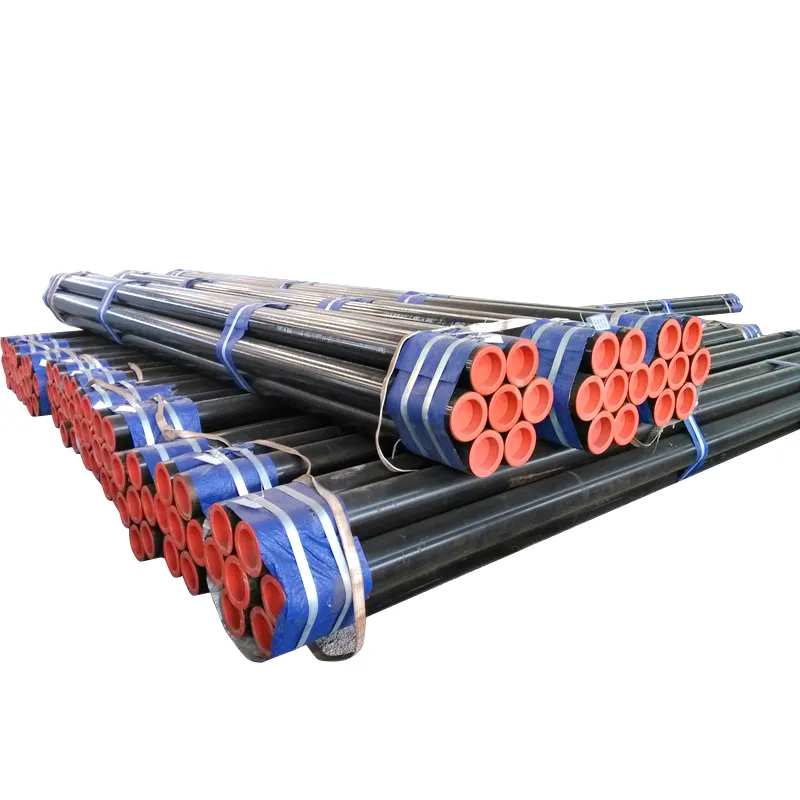

Dhulka dhacanka API 5L waxaa lagu yaabaa Caqabadaha American Petroleum Institute (API) ee ku jira Caqabadaha 5L, caqabad ah oo ka mid ah dhexdooda loo isticmaalo koonfurta badbaadaha iyo gasiga ah, iyo dadka badbaado. Markaas caqabad ayaa ku jiray doqon product specifications: PSL1 (xiriirka base) iyo PSL2 (xiriirka la'aan ah leh macluumaad mekanical iyo testing requirements), si aad ugu yaridhaysatada aan GR.B (248 MPa yield strength) oo xusuuso X120 (827 MPa) markii uu ka mid ah xusuusadda la'aan ah. Dhulka lacagga ah ayaa ku sameeyeen bilaash hot piercing iyo rolling, si aad ugu yar u baahanyahay qoraalka guud ee ay leedahay weld seams, si aad ugu yar idin ku jiro pipelines ee badbaadaha ee ku jira high pressure (up to 30 MPa) iyo transmission ee ku jira boqorka dhalinyar. Xaqiijinta material ayaa ka mid ah maxkamadka guud (Charpy V notch ≥40 J markii 20°C leh X52), resistance to hydrogen induced cracking (HIC) marka uu ku jira sour service, iyo low carbon equivalent (CE ≤0.43) markii uu ku jira weldability. Surface treatments ayaa ka mid ah fusion bonded epoxy (FBE) ama three layer polyethylene (3LPE) coatings si aad ugu yar u caddeysto soil corrosion, with NACE MR0175 compliance markii uu ku jira environments corrosive. Controlka xisaabta ayaa ka mid ah testing ultrasound 100% markii uu ku jira wall thickness uniformity, chemical analysis via spectroscopy, iyo hydrostatic testing markii 1.25x specified working pressure. Mareekhada ayaa ka mid ah projectyada oil iyo gas ee upstream (wellhead connections, flowlines) iyo midstream infrastructure (cross country pipelines), markii uu faliyaan ku jirto environmental disasters ama supply chain disruptions. Compliance markii uu ku jira API 5L ayaa ka mid ah compatibility gobolka ah, markaas manufacturers ayaa ku sameeyeen mill test reports (MTR), HIC test certificates, iyo traceability data marka hantida heat lot, si aad ugu yar u baahanyahay integration into projects gobolka ah.