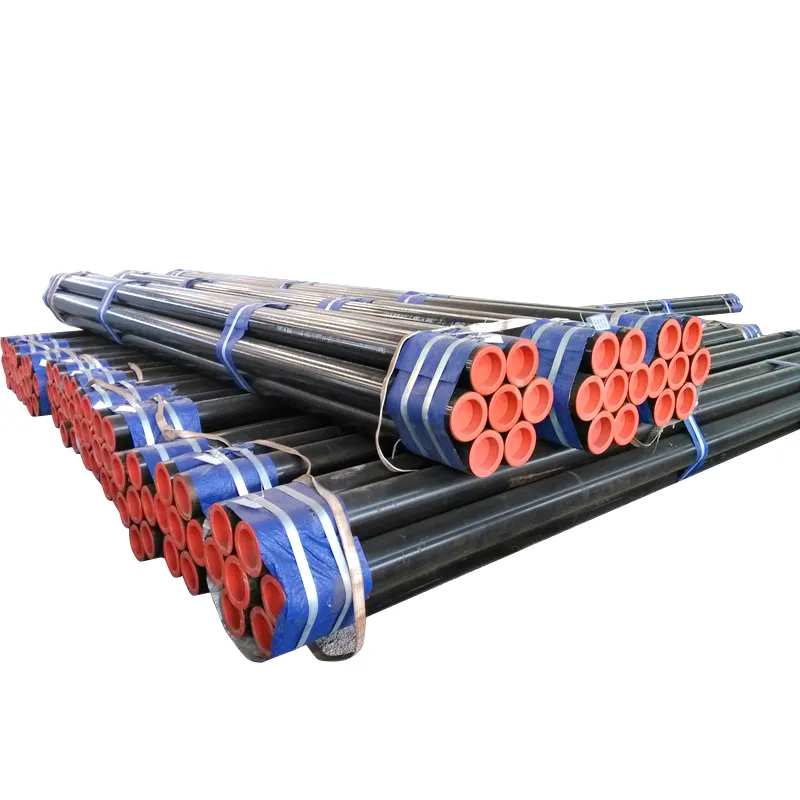

API 5L seamless steel pipe complies with the American Petroleum Institute (API) Specification 5L, a globally recognized standard for pipeline steel used in the transportation of oil, gas, and other fluids. This specification covers two product specifications: PSL1 (basic quality) and PSL2 (enhanced quality with stricter mechanical and testing requirements), along with grades ranging from GR.B (248 MPa yield strength) to X120 (827 MPa) for high strength applications. Seamless pipes are produced via hot piercing and rolling, creating a homogeneous structure without weld seams, making them ideal for high pressure (up to 30 MPa) and long distance transmission pipelines. Key material properties include high toughness (Charpy V notch ≥40 J at 20°C for X52), resistance to hydrogen induced cracking (HIC) in sour service, and low carbon equivalent (CE ≤0.43) for weldability. Surface treatments often include fusion bonded epoxy (FBE) or three layer polyethylene (3LPE) coatings to protect against soil corrosion, with NACE MR0175 compliance for corrosive environments. Quality control involves 100% ultrasonic testing for wall thickness uniformity, chemical analysis via spectroscopy, and hydrostatic testing at 1.25x the specified working pressure. These pipes are critical in upstream oil and gas projects (wellhead connections, flowlines) and midstream infrastructure (cross country pipelines), where failure could lead to environmental disasters or supply chain disruptions. Compliance with API 5L ensures global compatibility, with manufacturers providing mill test reports (MTR), HIC test certificates, and traceability data for each heat lot, enabling seamless integration into international projects.