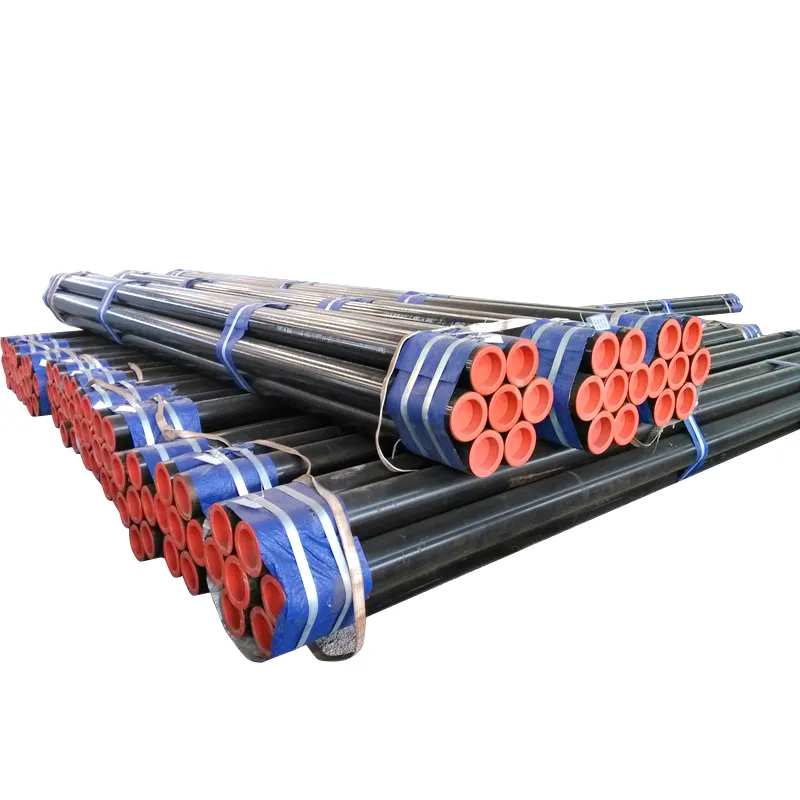

Oil and gas seamless steel pipe is engineered to withstand the extreme conditions of upstream exploration, midstream transportation, and downstream refining, where high pressure (up to 100 MPa), corrosive media (H₂S, CO₂), and low temperatures ( 40°C) are common. Materials include high strength low alloy (HSLA) steels (API 5L X65, X70), martensitic stainless steels (13Cr), and nickel based alloys (Inconel 625) for sour service, selected based on NACE MR0175/NACE MR0103 guidelines. The seamless manufacturing process—hot rolled piercing followed by cold drawing for precision—eliminates weld defects, ensuring integrity in critical applications like subsea pipelines, well casings, and refinery process lines. Key properties include: 1) high yield strength (550–860 MPa) to resist collapse under external pressure; 2) excellent fracture toughness (CTOD ≥0.3mm at 10°C); 3) anti corrosion resistance through alloy design (Cr ≥12% for pitting resistance). Surface treatments for offshore use may include zinc rich primers (80μm thickness) and glass flake epoxy coatings (300μm) to combat saltwater erosion. Quality assurance involves rigorous testing: hardness testing (HB 220–280), hydrogen permeability testing (ASTM G148), and full body radiographic inspection for pipelines operating in high consequence areas. These pipes are essential for maintaining uninterrupted energy supply, with manufacturers investing in R&D to develop next generation materials like ultra high strength X120 and corrosion resistant duplex stainless steels, reducing wall thickness and transportation costs without compromising safety.