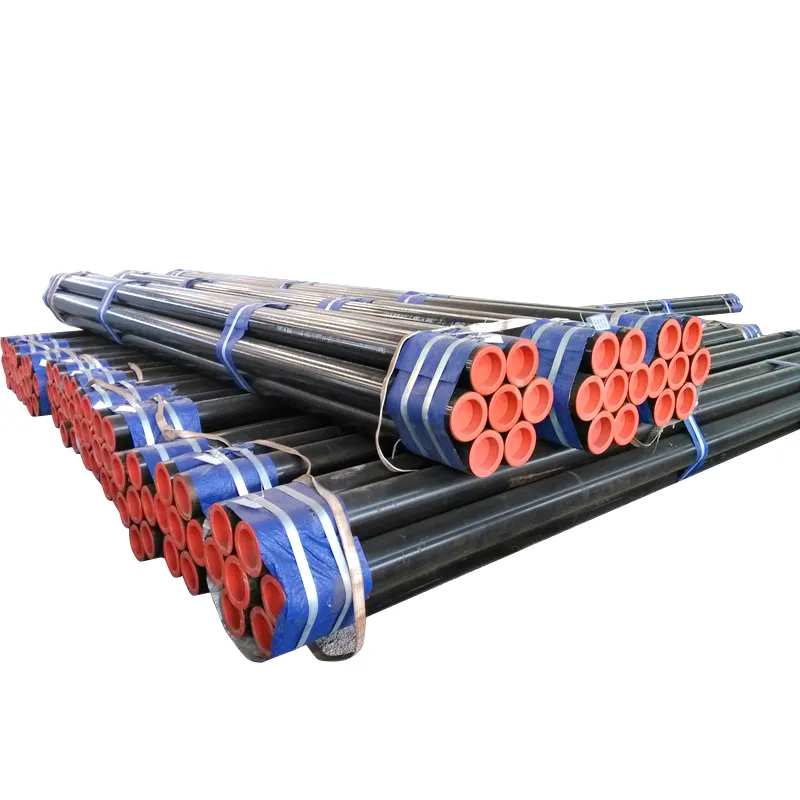

Corrosionresistant seamless steel pipe is engineered to combat degradation in aggressive environments, such as marine saltwater, chemical laden soils, or acidic industrial processes. Materials include austenitic stainless steels (316L, 904L), duplex steels (2205, 2507), and nickel based alloys (Hastelloy C 276), chosen for their inherent resistance to pitting, crevice corrosion, and stress corrosion cracking. The seamless manufacturing process eliminates weld related vulnerabilities, with cold working or heat treatment optimizing microstructures for maximum corrosion resistance—for example, 316L’s low carbon content (≤0.03%) prevents carbide precipitation during welding. Surface finishes range from mill finish (for general corrosion resistance) to electropolished (Ra ≤0.2μm) for hygiene critical applications (pharmaceuticals, food processing). Standards like ASTM A269 (stainless steel tubing) and NACE MR0175 (sour service) specify chemical composition (e.g., Mo 2–4% in 316L, Cr 25–27% in 2507 duplex) and testing methods (salt spray testing per ASTM B117 for 1,000+ hours). Applications include: offshore platform pipelines, chemical reactor cooling systems, and desalination plant heat exchangers. Suppliers often provide corrosion resistance maps (pH vs. temperature) to assist clients in material selection, along with post weld passivation services to restore the protective oxide layer and ensure long term reliability in harsh environments.