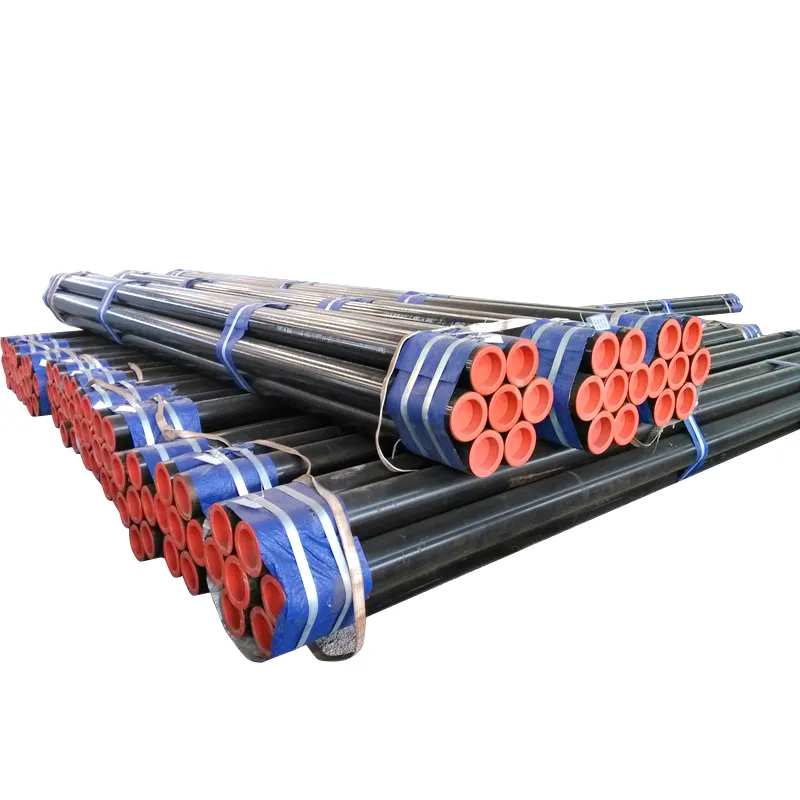

Hot rolled seamless steel pipe is produced by shaping heated steel billets into tubular forms at temperatures above the recrystallization point (1,100–1,300°C), resulting in products with excellent ductility and impact resistance. The process involves three main stages: 1) piercing, where a rotating billet is penetrated by a mandrel to form a hollow shell; 2) rolling, using automatic or semi automatic mills to reduce wall thickness and expand diameter; 3) sizing, to achieve final dimensions with OD tolerances of ±1% and wall thickness ±8%. Common materials include carbon steel (20#, ASTM A106 Grade B), low alloy steel (15CrMo, ASTM A335 P11), and stainless steel (316H), with yield strengths ranging from 250 MPa to 550 MPa. Hot rolled pipes are valued for their ability to handle large diameters (200–1,200mm) and thick walls (10–100mm), making them suitable for structural supports (bridge piers), high temperature pipelines (steam superheaters), and heavy machinery components (hydraulic cylinders). Surface finish is typically mill scale (black), though options like pickling (ASTM A967) or galvanization (ASTM A123) are available for corrosion prone environments. Mechanical properties include elongation ≥20% (for ductility) and bendability (180° around 3D mandrel), with applications spanning energy, construction, and industrial sectors where formability and cost effectiveness are prioritized over dimensional precision.