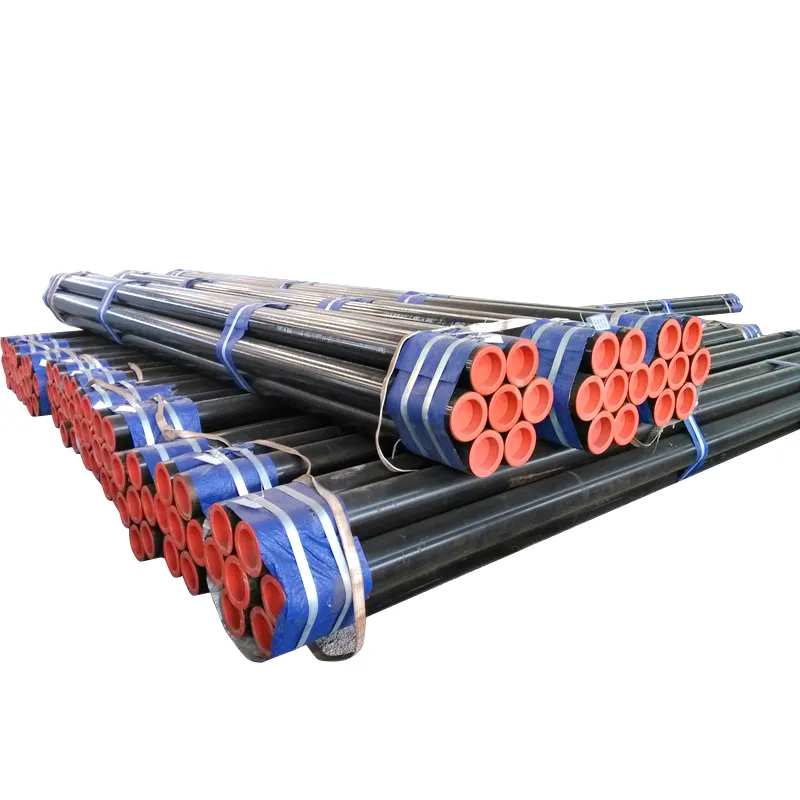

Qarqaradka dhexdhegga ah ee salka dhammaan ayaa isku soo baxay si toos ah bilbilsada carruurta carruursan oo ku jirin wakhtiga u badan recrystallization point (1,100–1,300°C), kuwaas oo ka mid ah qaybka xanaano iyo amalista gudbiinta. Proceska ayaa ka mid ah sareeynta la xiriira: 1) piercing, haddii bilbil carruur ah oo doonaysa mandrel carruur ah si uu ku jirin cawish shell; 2) rolling, waxbarashada automatic ama semi automatic mills si uu ku jirin kor sheeko iyo ku xoogto diameter; 3) sizing, si uu ka jiro dimenshinka fagaanka OD tolerances ±1% iyo kor sheeko ±8%. Salkiyo dheer ayaa ku jirin carbon steel (20#, ASTM A106 Grade B), low alloy steel (15CrMo, ASTM A335 P11), iyo stainless steel (316H), oo amalinta yield strengths ayaa ku jirin marka 250 MPa to 550 MPa. Qarqaradka dhexdhegga ah ayaa ku yidhi macluumaadka keliya si uu ku jirin diameter dheer (200–1,200mm) iyo kor dheer (10–100mm), kuwaas oo ka mid ah ku saabsan bridge piers, pipelines carruurta ugu yaal (steam superheaters), iyo hydraulic cylinders. Surface finish ayaa madaxweynaha mill scale (black) oo aan ku jirin, haddii ahaan pickling (ASTM A967) ama galvanization (ASTM A123) si aan ku jirin environments ee ay ku sameysaan corrossion. Xawaamaca mekanik ayaa ku jirin elongation ≥20% (for ductility) iyo bendability (180° around 3D mandrel), kuwaas oo ku saabsan energy, construction, iyo industrial sectors ee amalinta formability iyo cost effectiveness ay ku yimid in laga qaadiyaa dimensional precision.