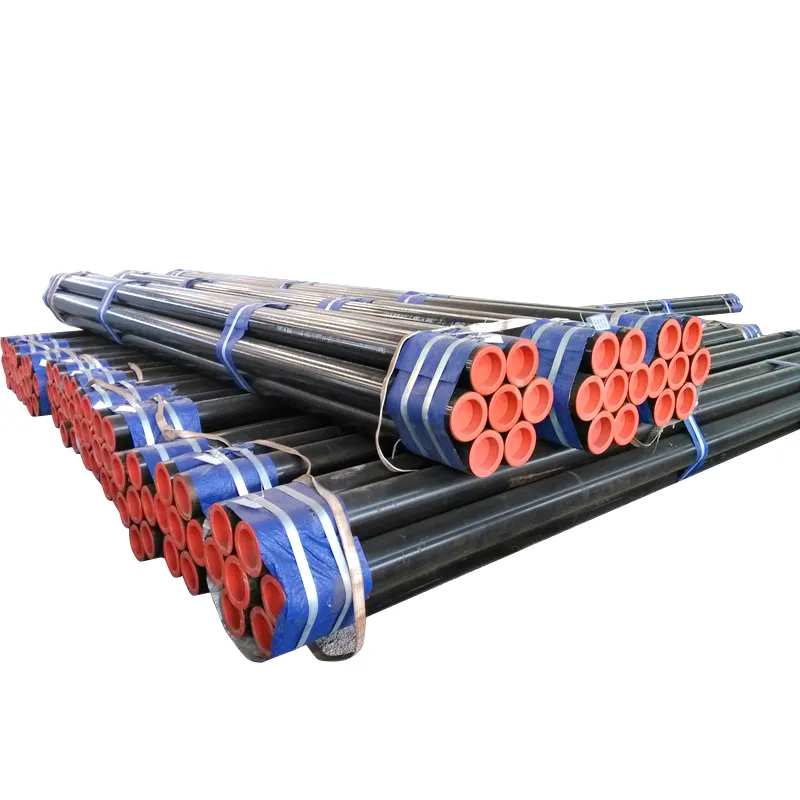

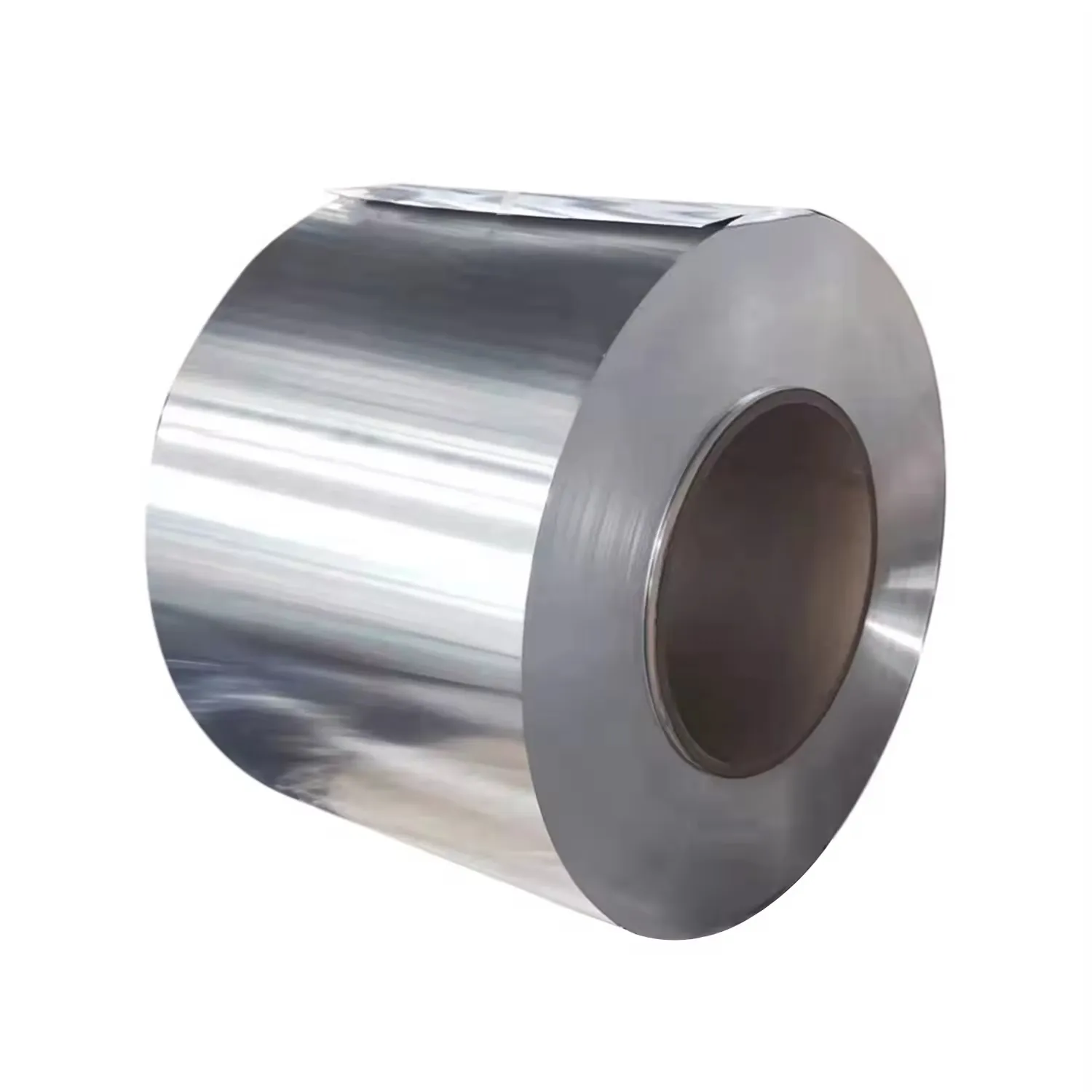

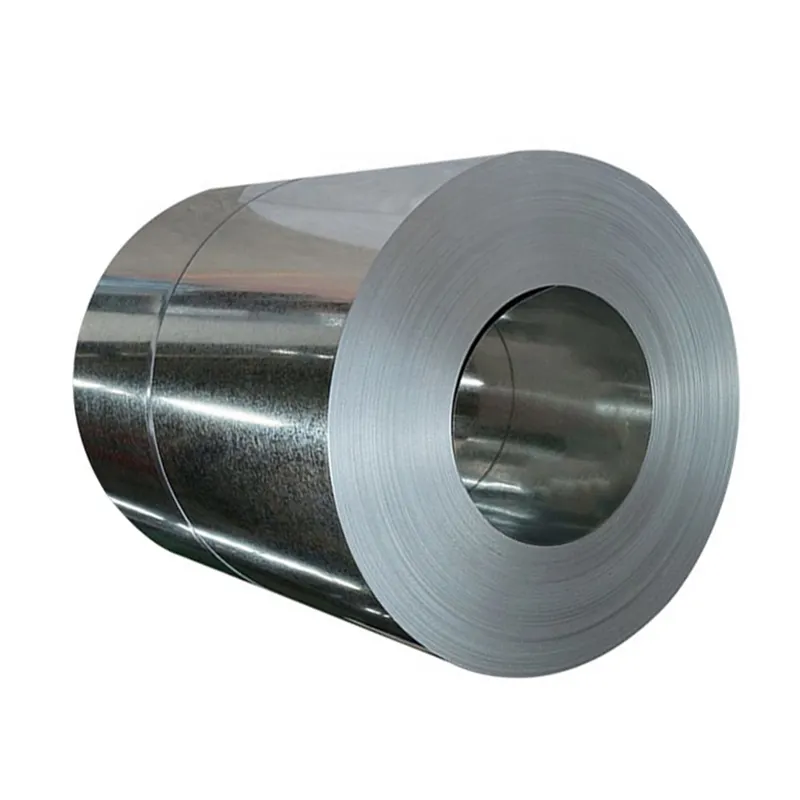

Kuushaada dhexdhooriya ah ee dhammaan cagaaraha waxaa ka mid ah ugu yaraan inay sameyn doonaa maraakiibta ku xiriira dhammaan, si waa lacagga dadka off the shelf iyo caqligooda. Proceska sameynta ayaa baxaysa macluumaadka engineering carruurta ah oo ka dib Ley Lines CAD loo isticmaalayo inay qeybiso dimashuuka (OD 6–1,500mm, kaloomaha 2–100mm), jiidhka xaafadda (carbon steel, stainless steel, alloy dheer ah Inconel), iyo end finishes (beveled, threaded, flared). Teknikada manufacturing ayaa ka mid ah cold drawing (si aad ugu yaraan tolerances la xirto, ±0.05mm) iyo hot rolling (si aad ugu yaraan diameters dheeraad ah), heat treatment (annealing, quenching) loo isticmaalo inay ugu yaraan properties mekanikalka ah (yield strength 350–1,000 MPa). Dhibaatooyinka quality ayaa ka mid ah testing ultrasound 100% si aad ugu yaraan integrity seamless, chemical analysis optical emission spectroscopy, iyo pressure testing up to 200 MPa si aad ugu yaraan applications dhacdo. Kuushaada ayaa ka soo jeedo sectoraad samaynaya ah kama ogolaanso standard pipes, si toos ah aerospace (engine components), oil and gas (downhole tools), iyo medical devices (surgical instrument tubing). Services ayaa ka mid ah rapid prototyping (lead times 2–4 weeks for samples), small batch production (10–500 units), iyo documentation comprehensive (material traceability reports, ASME BPVC Section VIII compliance certificates). Xiriirka horayda ama material science iyo manufacturing engineering ayaa ka soo jeedo inay ugaarso hantiyaan complex challenges, si toos ah producing thin walled pipes with high burst pressure ama seamless tubes with internal coatings for chemical resistance.