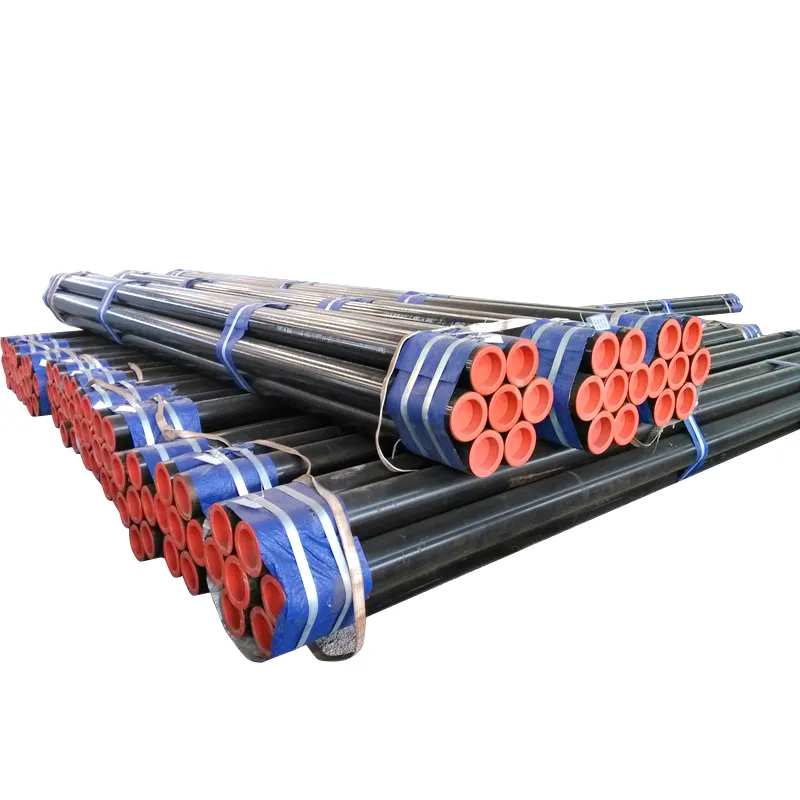

Custom seamless steel pipe suppliers specialize in producing non standard tubular products tailored to unique project requirements, bridging the gap between off the shelf sizes and specialized applications. The customization process begins with detailed engineering collaboration, using CAD models to define dimensions (OD 6–1,500mm, wall thickness 2–100mm), material grades (carbon steel, stainless steel, exotic alloys like Inconel), and end finishes (beveled, threaded, flared). Manufacturing techniques include cold drawing (for precision tolerances, ±0.05mm) and hot rolling (for large diameters), with heat treatment (annealing, quenching) to achieve desired mechanical properties (yield strength 350–1,000 MPa). Quality control involves 100% ultrasonic testing for seamless integrity, chemical analysis via optical emission spectroscopy, and pressure testing up to 200 MPa for high pressure applications. These suppliers serve industries like aerospace (engine components), oil and gas (downhole tools), and medical devices (surgical instrument tubing), where standard pipes fail to meet performance or fit requirements. Services often include rapid prototyping (2–4 week lead times for samples), small batch production (10–500 units), and comprehensive documentation (material traceability reports, ASME BPVC Section VIII compliance certificates). Their expertise in material science and manufacturing engineering allows them to solve complex challenges, such as producing thin walled pipes with high burst pressure or seamless tubes with internal coatings for chemical resistance.