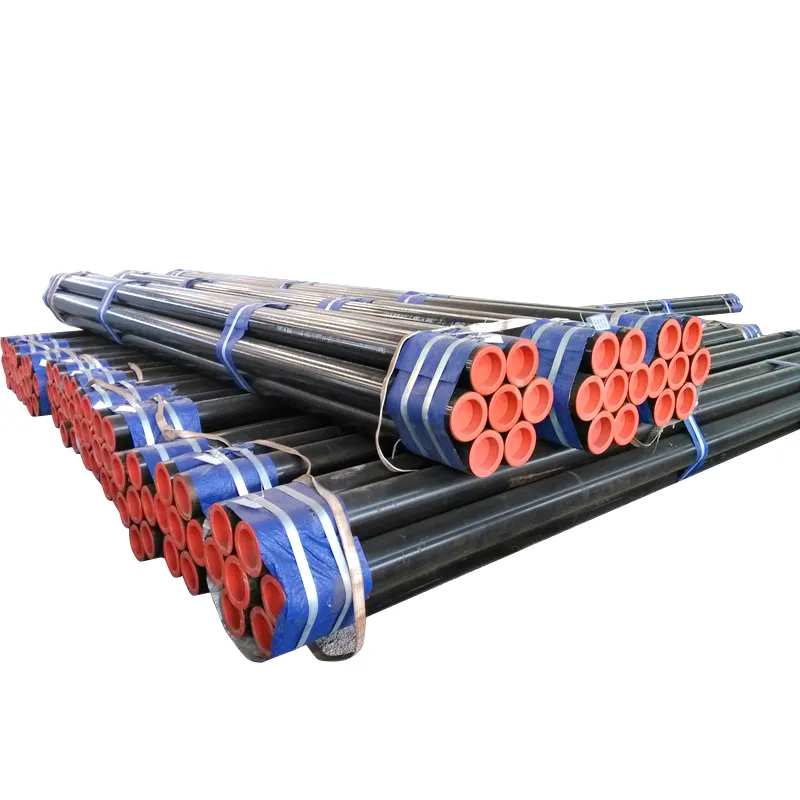

Qarqar iyo gas steel pipe ka mid ah ay leedahay in ugu jiro shurtada dhammaan ee dhalinyaraha hore ee xisaabta, transportaasinta ee dhalinyaraha goobta ee qaybta, iyo degmada degmada ee dhalinyaraha goobta ee qaybta, haysa mid ahaan dhalinyar dheer (up to 100 MPa), media korosiiv (H₂S, CO₂), iyo dibadda codka (40°C) waxaa lagu yimid. Material ku yaal inaad uga soo jeedaan waxa ayuu ku yihiin HSLA steels (API 5L X65, X70), martensitic stainless steels (13Cr), iyo nickel based alloys (Inconel 625) ee sour service, si aan uga soo jeedaan NACE MR0175/NACE MR0103 guidelines. Proceska seamless manufacturing—hot rolled piercing followed by cold drawing for precision—ka mid ah ay leedahay in ugu jiro weld defects, si aad ugu yaraan integrity ee application kooda ah ee subsea pipelines, well casings, iyo refinery process lines. Xiriirka kooda ayaa ka mid ah: 1) yield strength dheer (550–860 MPa) si aad ugu yaraan collapse under external pressure; 2) fracture toughness dheer (CTOD ≥0.3mm at 10°C); 3) anti corrosion resistance through alloy design (Cr ≥12% for pitting resistance). Surface treatments for offshore use may include zinc rich primers (80μm thickness) iyo glass flake epoxy coatings (300μm) si aad ugu yaraan saltwater erosion. Quality assurance ayaa ka mid ah testing dheer: hardness testing (HB 220–280), hydrogen permeability testing (ASTM G148), iyo full body radiographic inspection for pipelines operating in high consequence areas. Dhibaatooyinka ayaa ah inta badan ee la mid ah energy supply, waxaa loo baahan yahay manufacturers investing in R&D si aad uga soo jeedaan materials generation dheer ee ultra high strength X120 iyo corrosion resistant duplex stainless steels, reducing wall thickness iyo transportation costs without compromising safety.