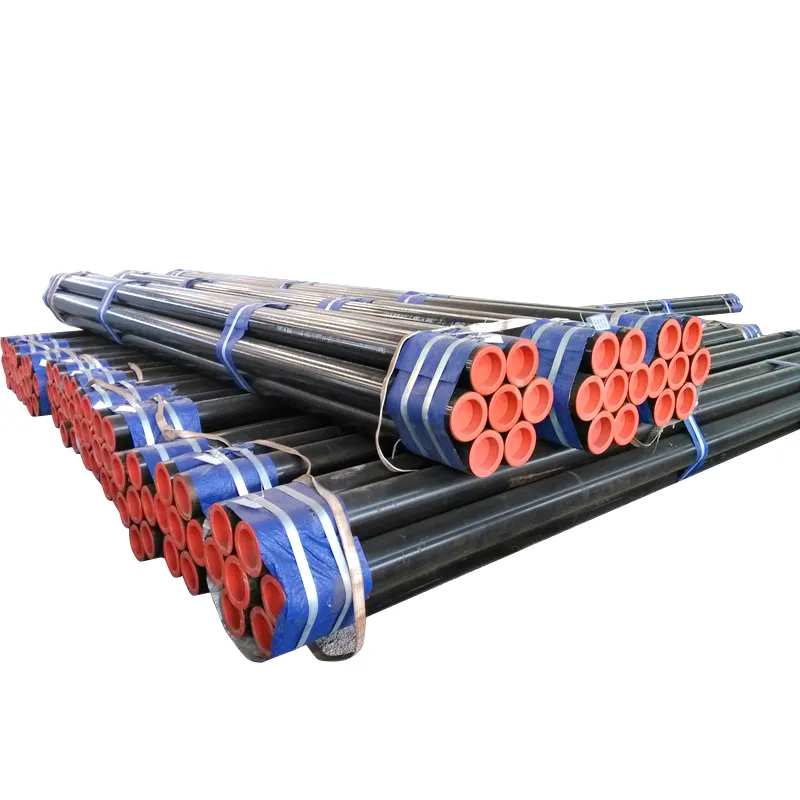

ASTM A53 seamless steel pipe conforms to the American standard for carbon steel pipes, offering a versatile solution for mechanical and pressure applications where weld seams are undesirable. Unlike the welded Type S/Type F covered in ASTM A53, seamless pipes are formed by piercing a steel billet into a hollow tube, resulting in uniform wall thickness and no longitudinal weld, making them suitable for higher pressures (up to 20 MPa) and more critical environments. The standard covers two grades: Grade A (yield strength 248 MPa) for general use and Grade B (345 MPa) for higher strength applications, with material composition limits (carbon ≤0.25% for Grade B) to ensure weldability and ductility (elongation ≥25%). Seamless pipes under ASTM A53 are available in nominal diameters 1/8” to 26”, with wall thicknesses conforming to Schedule 10 to Schedule 160, allowing flexibility in pressure and structural designs. Common applications include: steam pipelines (Grade B for higher temperature resistance), mechanical drive shafts, and structural supports in bridges or heavy machinery. Surface treatments include black (uncoated), galvanized (ASTM A123), or painted, with galvanized seamless pipes often used in water supply systems for their corrosion resistance. Compliance with ASTM A53 requires hydrostatic testing at 1.5x the specified working pressure and chemical analysis to verify alloy composition, ensuring compatibility with fittings and joining methods (welded, threaded) across North American and international projects that adopt American standards.