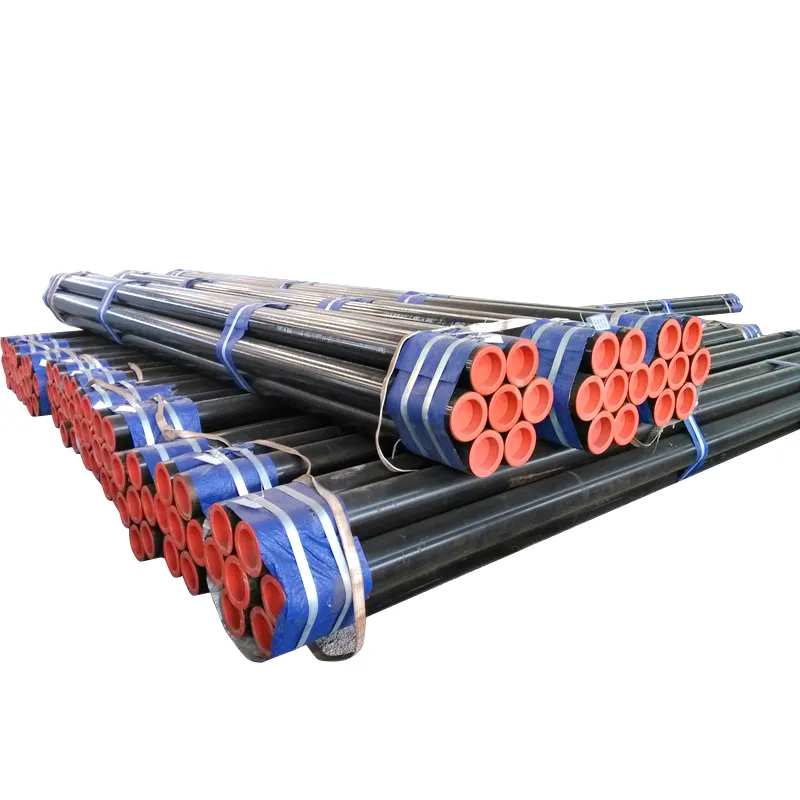

Industrial highpressure seamless pipe is designed to transport fluids and gases at pressures exceeding 10 MPa, critical for applications in oil and gas extraction, chemical processing, and power generation. These pipes are manufactured from high strength alloy steels (e.g., API 5L X70, ASTM A106 Grade C) through hot piercing and rolling, creating a homogeneous structure without weld seams to withstand extreme internal and external pressures. Key standards include API 5L (pipeline steel), ASTM A333 (cryogenic service), and ASME B31.3 (process piping), specifying minimum yield strength (485–690 MPa), toughness (Charpy V notch ≥40 J at 20°C), and resistance to hydrogen induced cracking (HIC) in sour gas environments. Mechanical testing includes hydrostatic pressure tests (1.5x working pressure for 30 minutes), hardness testing (HB 180–240), and metallographic analysis to ensure grain uniformity. Surface coatings for corrosion protection may include three layer PE (for offshore pipelines) or fusion bonded epoxy . Applications include: high pressure gas transmission (natural gas pipelines), hydraulic systems in heavy machinery, and steam generation in power plants. Design considerations involve finite element analysis to model stress concentrations at bends or tees, while strict quality assurance ensures compliance with safety critical industry standards, minimizing the risk of catastrophic failures in high pressure systems.