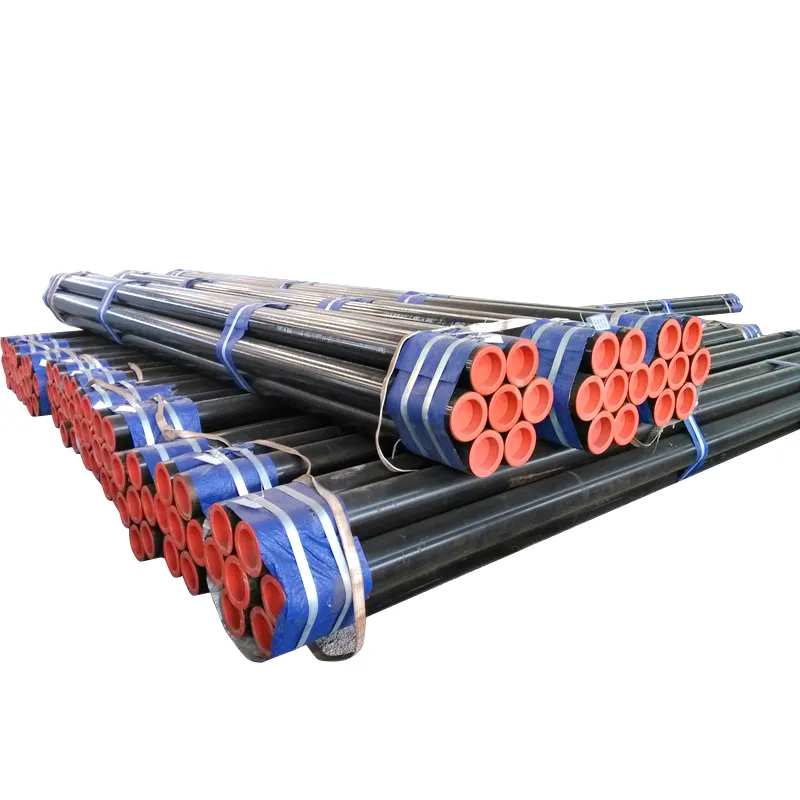

A seamless steel pipe factory is a highly specialized manufacturing facility integrating raw material processing, thermal treatment, and precision machining to produce tubular products without longitudinal welds. The production process begins with steel billets (100–300mm diameter) heated to 1,200–1,300°C, then pierced into hollow shells using a Mannesmann mill. These shells are expanded via rolling mills (automatic, semi automatic) to achieve the desired outer diameter (OD 50–1,200mm) and wall thickness (5–100mm), followed by cold drawing or cold rolling for tight tolerances (OD ±0.5%, wall thickness ±5%). Key equipment includes 环形炉 for uniform heating, piercing mills with carbide rolls, and NDT lines for 100% flaw detection. Factories producing high end products (e.g., boiler tubes, oil country tubular goods) incorporate heat treatment furnaces (annealing, quenching tempering) to optimize mechanical properties, with computer controlled systems ensuring temperature uniformity (±5°C). Quality control labs are equipped with tensile testing machines (capable of 2,000 kN), impact testers, and metallographic microscopes for grain size analysis (ASTM E112 Grade 6–8). Production capacities range from 50,000 tons/year for medium sized facilities to 500,000 tons/year for integrated mills, serving global markets with certifications like API 5CT, ISO 3183, and CE PED Module B.