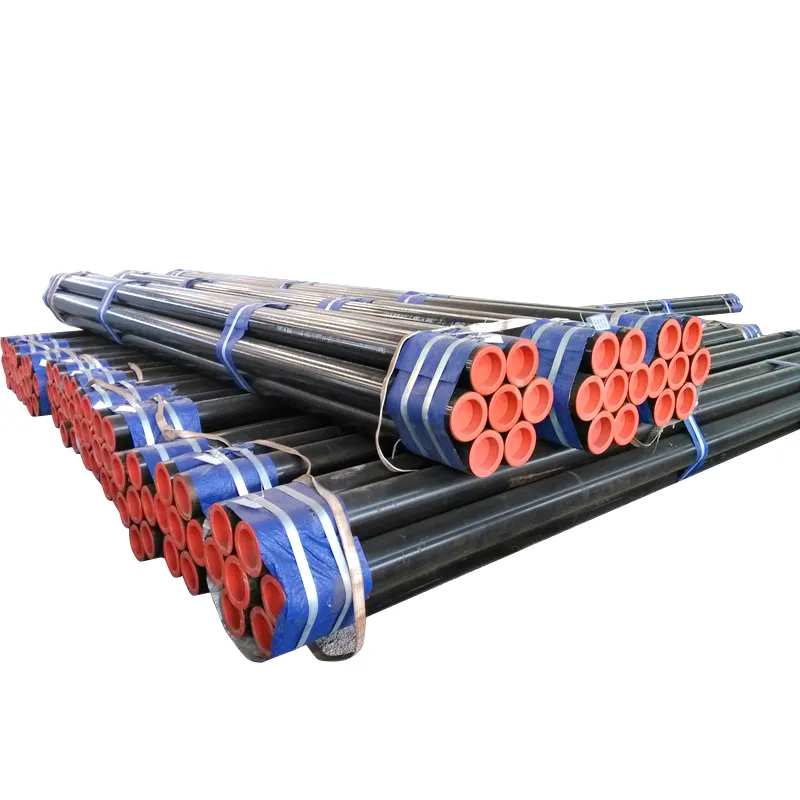

Carbon steel seamless pipe is a foundational industrial material, prized for its balance of strength, affordability, and versatility in non corrosive to moderately corrosive environments. Manufactured from carbon steel grades with 0.12–0.30% carbon content (e.g., ASTM A106 Grade B, GB/T 8163 20#), these pipes offer yield strengths 248–415 MPa and tensile strengths 415–620 MPa, suitable for pressure systems up to 16 MPa. The seamless structure eliminates weld related weaknesses, making them ideal for applications requiring high reliability, such as boiler feedwater lines, mechanical drive shafts, and structural supports in seismic zones. Dimensional ranges cover OD 15–600mm, wall thickness 2–40mm, with standard lengths 6–12 meters, customizable via cutting and beveling. Surface treatments vary from bare steel (painted on site) to protective coatings: hot dip galvanization (85μm zinc layer for outdoor use), epoxy lining (300μm for water pipelines), and bitumen wrapping. Quality control includes hydrostatic testing (1.5x working pressure), ultrasonic testing for wall thickness uniformity, and chemical analysis to ensure sulfur/phosphorus content ≤0.045% for weldability. Applications span water supply networks, industrial piping, and building frameworks, with compliance to standards like ASME B31.1 (power piping) and EN 10216 1 (mechanical tubing) ensuring global acceptability.