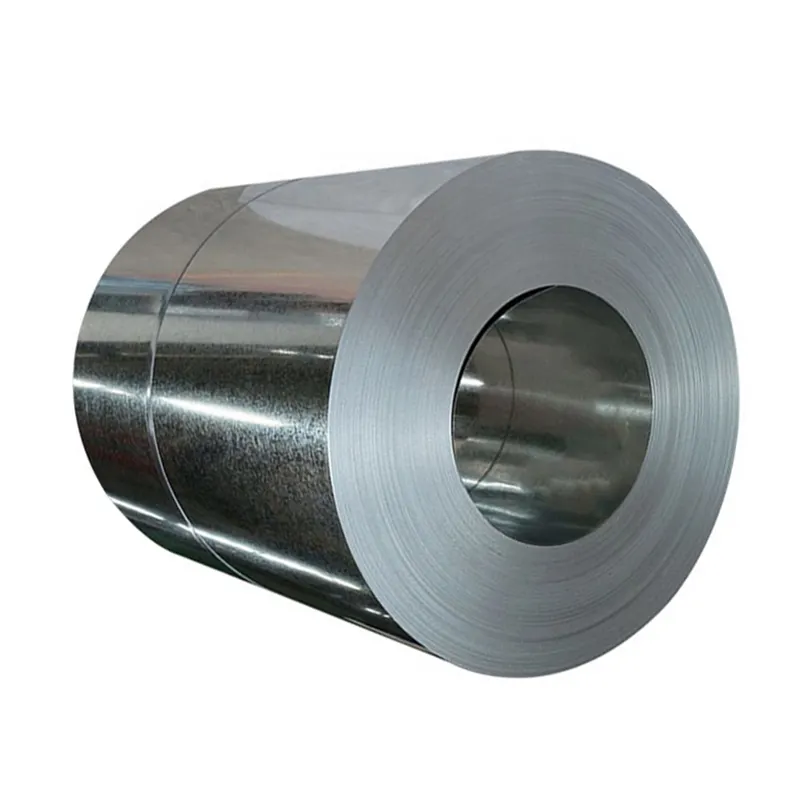

Carbon steel coils for containers are specialized materials designed for manufacturing shipping containers, storage tanks, and other containerized structures, prioritizing durability, formability, and corrosion resistance. These coils typically use low carbon steel with controlled chemical composition (carbon ≤0.20%) to ensure good weldability and ductility for complex forming operations. The cold rolled or hot rolled coils have precise thicknesses (0.8mm to 4mm) and widths (1,000mm to 1,500mm) to match container fabrication requirements. Surface quality is critical, with coils undergoing rigorous inspection to eliminate defects that could compromise container integrity. Corrosion protection is often enhanced through galvanizing (hot dip or electroplating) or pre painting with anti corrosive coatings, especially for outdoor container applications. Mechanical properties like tensile strength (400 550 MPa) and yield strength (235 355 MPa) are optimized to withstand stacking loads, transportation stresses, and environmental factors. Coils are supplied in large rolls for continuous manufacturing, reducing material waste and production time. Container manufacturers use these coils to fabricate side panels, roofs, floors, and structural supports, relying on the coil’s formability for bending and welding operations. With the global expansion of logistics and shipping industries, demand for carbon steel coils for containers continues to grow, driven by the need for durable, cost effective storage and transportation solutions.