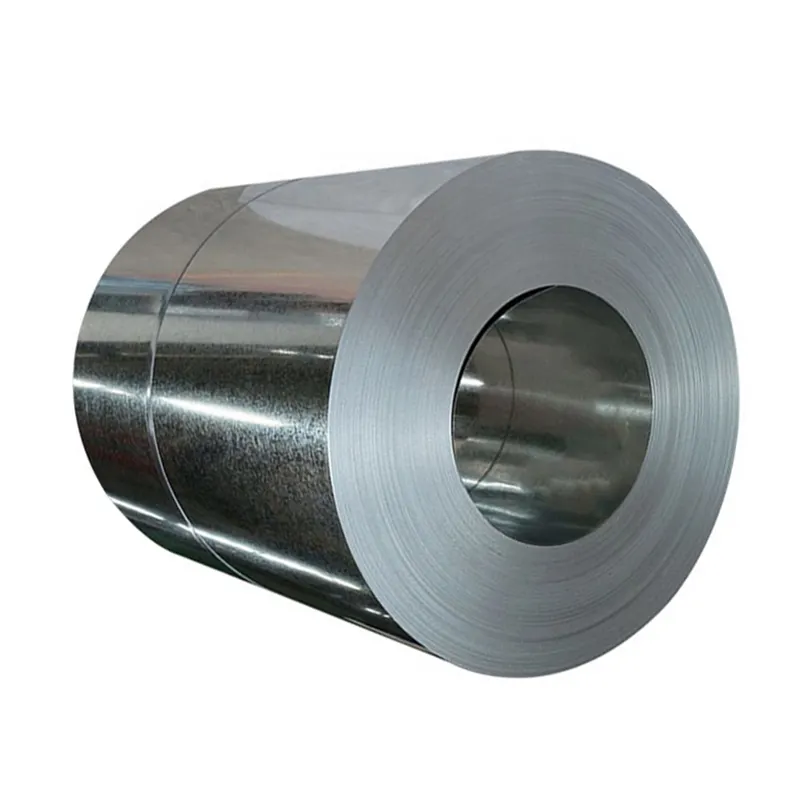

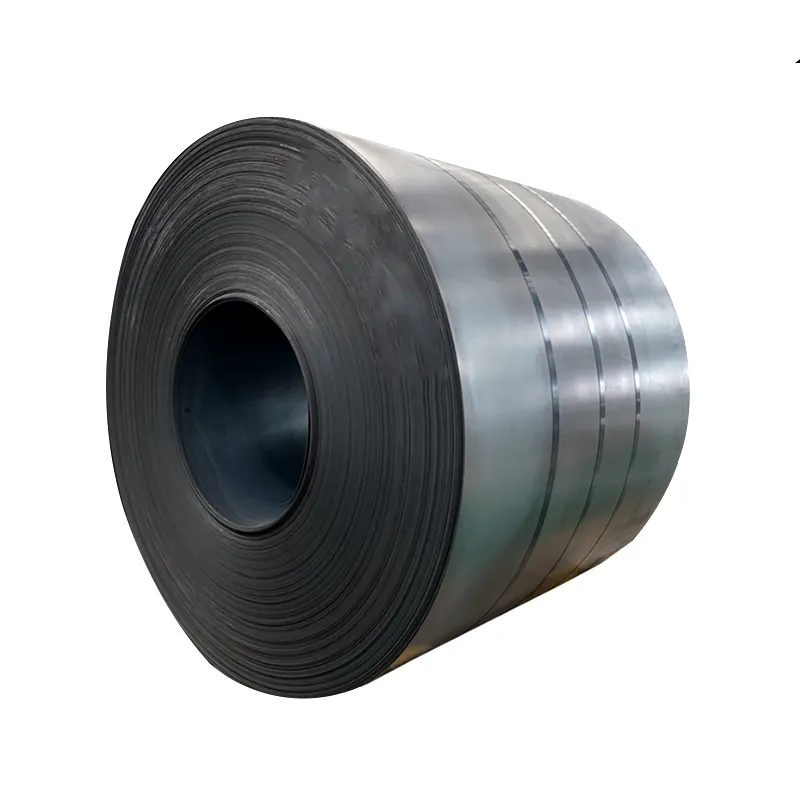

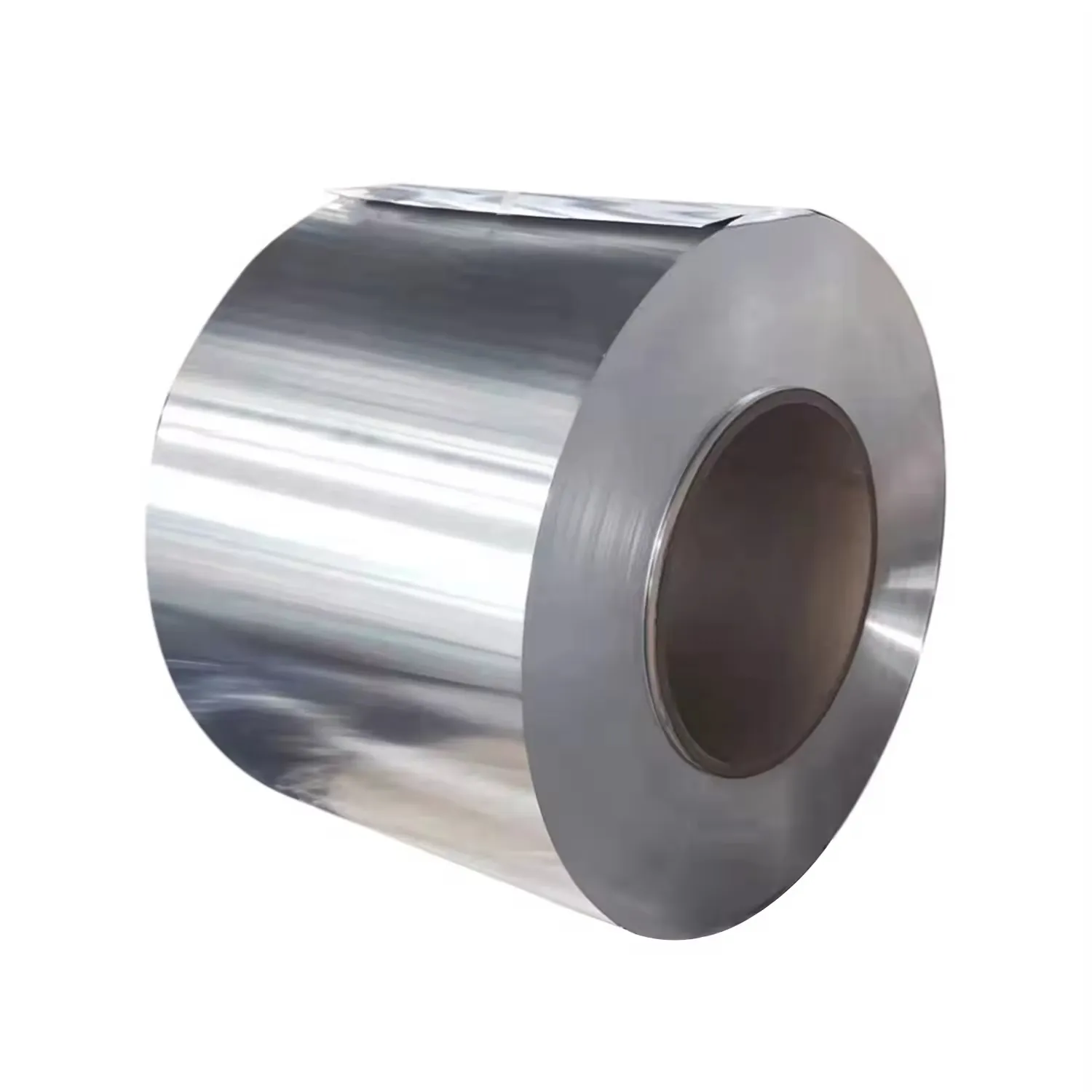

A36 carbon steel coil is a widely used structural grade known for its balanced mechanical properties, weldability, and affordability, making it suitable for various general construction and manufacturing applications. Specified by ASTM A36, this low carbon steel has a carbon content ≤0.29%, manganese ≤1.65%, and yield strength ≥250 MPa, with tensile strength ranging from 400 to 550 MPa. A36 coils are typically hot rolled, offering good ductility and formability for bending, stamping, and welding operations. The microstructure consists of ferrite and pearlite, providing a balance of strength and toughness. Surface finish is moderate, with some scale from hot rolling, but can be further processed (pickling, galvanizing) for improved aesthetics or corrosion resistance. A36 coils are available in various thicknesses (3mm to 100mm) and widths (up to 2,500mm), catering to projects like building frames, bridge supports, machinery bases, and storage tanks. Weldability is a key advantage, with A36 steel easily welded by common processes (SMAW, GMAW) without requiring preheating for most applications. While not designed for high temperature or severe corrosion environments, A36 coils offer cost effective structural support in moderate conditions. Engineers appreciate its versatility and reliability, making A36 carbon steel coil a staple in general construction and industrial manufacturing.