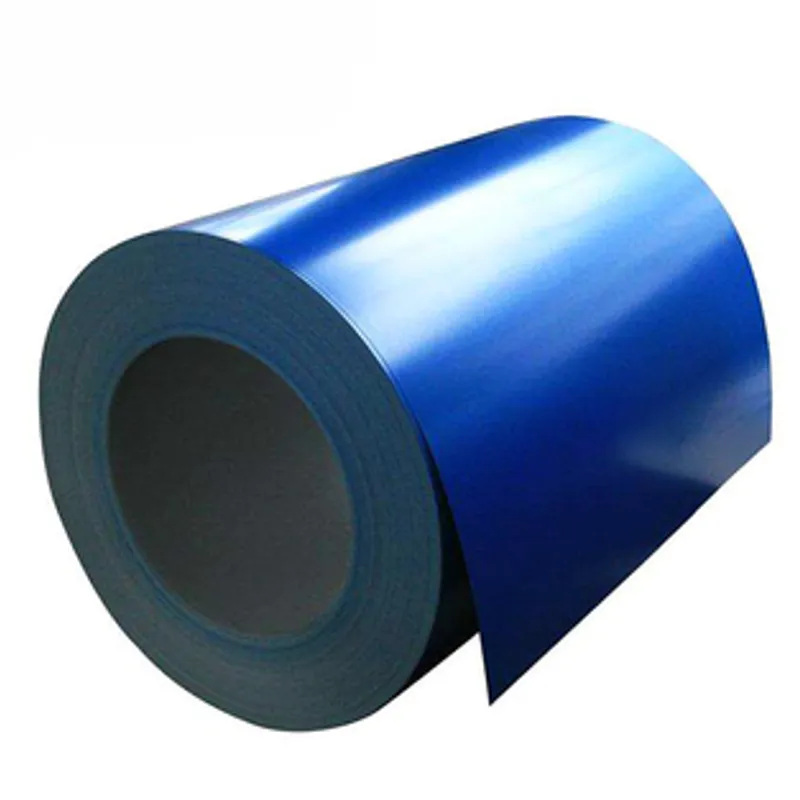

PPGI, or Pre Painted Galvanized Iron, stands out as a cost effective material in various industries due to its unique combination of protective coatings and pre finished surface treatments. The cost effectiveness of PPGI originates from multiple factors, starting with its production process. By applying a protective zinc layer through galvanization and a top organic paint layer in a continuous coil coating line, manufacturers can achieve high volume production with minimized material waste. This streamlined manufacturing reduces both material and labor costs compared to post painting galvanized sheets, where each sheet would need individual painting processes.Another aspect is its long term cost savings. The pre painted surface eliminates the need for frequent maintenance or repainting, which is a significant expense for structures like roofing, cladding, and industrial equipment. In environments with moderate corrosive conditions, PPGI can maintain its aesthetic and protective properties for 10 to 20 years, depending on the paint system and substrate quality. This longevity reduces lifecycle costs, making it a preferred choice over cheaper but less durable materials like plain galvanized steel or uncoated metals that require regular upkeep.Additionally, PPGI’s versatility in applications contributes to its cost efficiency. It can be easily formed, cut, and installed using standard metalworking tools, reducing installation time and labor costs. For large scale construction projects, the ability to handle large coil sizes and produce custom lengths without significant waste further enhances cost savings. The material’s compatibility with various design requirements, such as different color options and surface textures, also means it can meet aesthetic needs without additional finishing costs, making it a balanced choice between performance and budget.