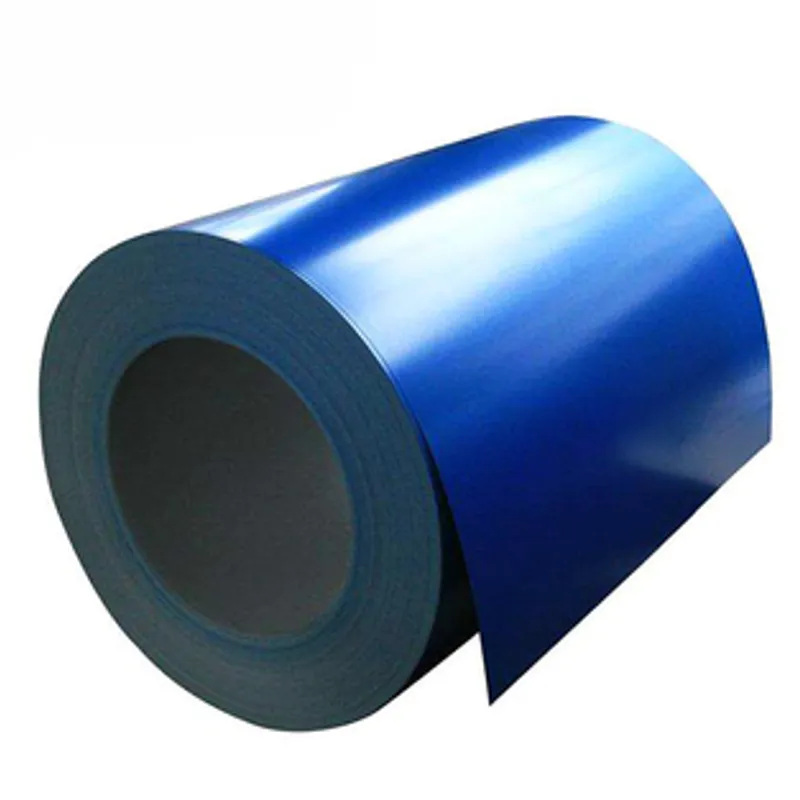

The longevity of PPGI sheets is a result of their multi layer protective system and rigorous manufacturing processes, making them suitable for applications requiring decades of reliable performance. The galvanized zinc layer, typically ranging from 20 to 275 grams per square meter in coating weight, provides a sacrificial barrier that slowly erodes over time while protecting the underlying steel. This zinc layer’s thickness can be customized based on the intended environment—higher weights for highly corrosive settings like chemical plants or marine environments, and lower weights for less aggressive climates.Above the zinc, the paint system is formulated for long term UV resistance and color stability. Modern coatings use advanced pigments and binders that resist fading and chalking, even after years of exposure to sunlight. For example, PVDF coatings have been proven to maintain over 80% of their original gloss after 20 years in tropical climates, significantly outperforming standard paint systems. The adhesion between the zinc layer, primer, and topcoat is critical for longevity; poor adhesion can lead to coating delamination, especially in fluctuating temperatures or mechanical stress environments.Manufacturers also implement quality control measures such as cross cut adhesion tests, bend tests, and salt spray resistance checks to ensure the coating system remains intact over time. In roofing applications, PPGI long lasting sheets can reduce the need for frequent replacements, which is particularly important for large commercial buildings where downtime and replacement costs are high. Their ability to withstand cyclic loading, such as thermal expansion and contraction, without developing cracks or fractures further contributes to their extended service life, making them a sustainable choice for infrastructure projects that require minimal maintenance over decades.