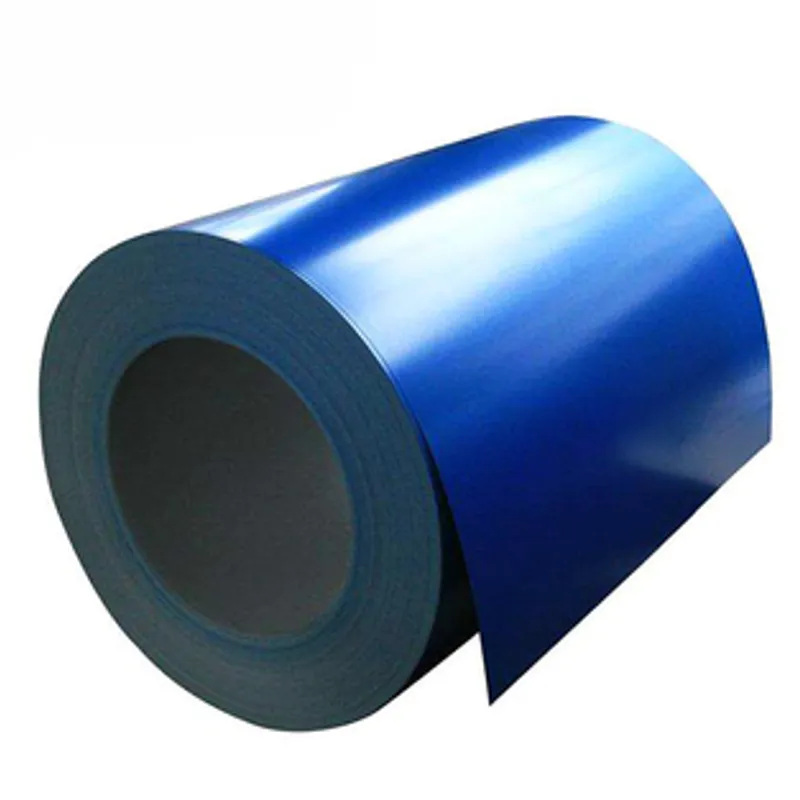

A PPGI specification sheet is a detailed technical document that outlines the material’s properties, dimensions, coating systems, and performance standards, serving as a critical reference for engineers, architects, and buyers. The sheet typically includes sections on substrate properties (steel grade, thickness, mechanical strength), galvanization details (coating weight, type—zinc, zinc aluminum alloy), and paint system specifications (coating type, color, gloss, adhesion properties).Key parameters include the steel’s yield strength (e.g., G550 for high strength applications), zinc coating weight (e.g., Z275 indicating 275 g/m² of zinc), and paint system details such as the type of resin (polyester, PVDF), number of coats, and color code. Performance data such as salt spray resistance (hours before red rust), UV resistance (years of color retention), and bend test results (mandrel diameter for coating adhesion) are also included to validate the material’s suitability for specific environments.Specification sheets must comply with international standards like ASTM A924 (for coated steel sheets), ISO 16773 (for organic coatings), or regional standards like JIS G3302 in Japan. They also often include manufacturing process details, quality control procedures, and recommended installation guidelines to ensure proper use. For global projects, specification sheets are crucial for communicating technical requirements across different cultures and regulatory environments, ensuring that the PPGI meets local building codes and performance expectations.