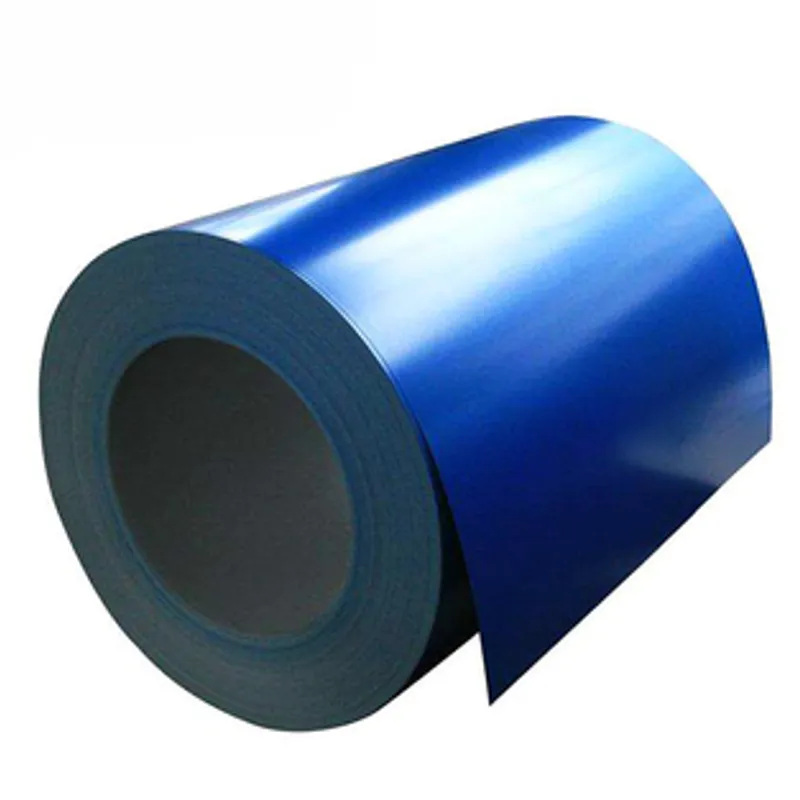

As a leading PPGI sheet manufacturer, Shandong Baotai Metal Materials Group Co., Ltd. has established itself as a trusted provider of high quality pre painted galvanized iron sheets, combining advanced manufacturing technology, strict quality control, and a customer centric approach. With over 20 years of industry experience, we have perfected the art of producing PPGI sheets that meet the diverse needs of clients worldwide, from small scale enterprises to large industrial projects.Our manufacturing facility is equipped with state of the art production lines that integrate precision engineering and automated processes. The production of PPGI sheets begins with the selection of premium grade galvanized steel substrates, sourced from reputable domestic steel companies such as Laigang, Angang, Baosteel, and Taigang. This ensures that the base material meets the highest standards of strength and corrosion resistance.The manufacturing process comprises several key stages. First, the galvanized steel coils are uncoiled and pre treated to remove any surface impurities, ensuring optimal adhesion of the paint coating. This pre treatment includes degreasing, washing, and chemical conversion coating, which creates a micro rough surface for better paint bonding. Next, the coils pass through the painting section, where they are coated with organic paint systems using advanced roller coating technology. We offer a variety of coating options, including polyester (PE), silicon modified polyester (SMP), and fluorocarbon (PVDF), each designed for specific performance requirements and environmental conditions.Color customization is a key feature of our manufacturing capabilities. We maintain a comprehensive color library with hundreds of standard colors, and we also offer custom color matching services to meet specific design requirements. Our paint systems are formulated to provide excellent color stability, UV resistance, and chemical resistance, ensuring that the sheets maintain their aesthetic appeal and protective properties over time.After painting, the coils undergo a curing process in a controlled oven to ensure the paint fully bonds with the galvanized substrate. This step is critical for achieving the desired mechanical properties, such as flexibility and impact resistance. The cured coils are then inspected for quality, including thickness uniformity, surface finish, and coating adhesion, before being coiled or cut into sheets of various sizes.As a manufacturer, we pride ourselves on our ability to offer highly customized PPGI sheets. We understand that different industries and applications have unique requirements, so we provide flexibility in sheet thickness (0.12mm to 2.0mm), width (up to 1,500mm), and length (customizable to project needs). Additionally, we offer value added processing services such as slitting, cut to length, punching, and embossing, which can be tailored to meet specific customer requirements. This level of customization allows us to serve a wide range of markets, including construction, automotive, appliance, and advertising.Quality control is integrated throughout our manufacturing process. Our dedicated quality assurance team uses advanced testing equipment to verify the performance of each batch of PPGI sheets. Tests include salt spray testing to evaluate corrosion resistance, cross cut testing for paint adhesion, impact testing to measure durability, and spectrophotometric analysis to ensure color accuracy. We are certified to international standards such as ISO, CE, and SGS, demonstrating our commitment to maintaining the highest quality levels.As a responsible manufacturer, we are also committed to sustainable production practices. We invest in energy efficient equipment and processes to reduce our carbon footprint, and we implement strict waste management systems to minimize environmental impact. Our paint systems are formulated to have low volatile organic compound (VOC) emissions, aligning with global environmental regulations.Our manufacturing capabilities are supported by a strong research and development team, which continuously explores new technologies and materials to improve the performance of our PPGI sheets. We stay abreast of industry trends and customer needs, developing innovative solutions for emerging applications. Whether it's enhancing fire resistance for construction projects or improving formability for automotive components, our R&D efforts ensure that we remain at the cutting edge of PPGI sheet manufacturing.Customer service is another pillar of our manufacturing philosophy. We work closely with clients from the initial inquiry stage, providing technical guidance on material selection and specification. Our sales team offers transparent communication throughout the order process, from production scheduling to delivery, ensuring that clients are kept informed at every step. We also provide after sales support, addressing any questions or concerns regarding product use and maintenance.In summary, as a PPGI sheet manufacturer, Shandong Baotai combines technical expertise, advanced manufacturing facilities, and a customer focused approach to deliver high quality products that meet the most demanding requirements. Our commitment to quality, customization, and sustainability has made us a preferred partner for clients worldwide, and we continue to strive for excellence in every aspect of our manufacturing operations.