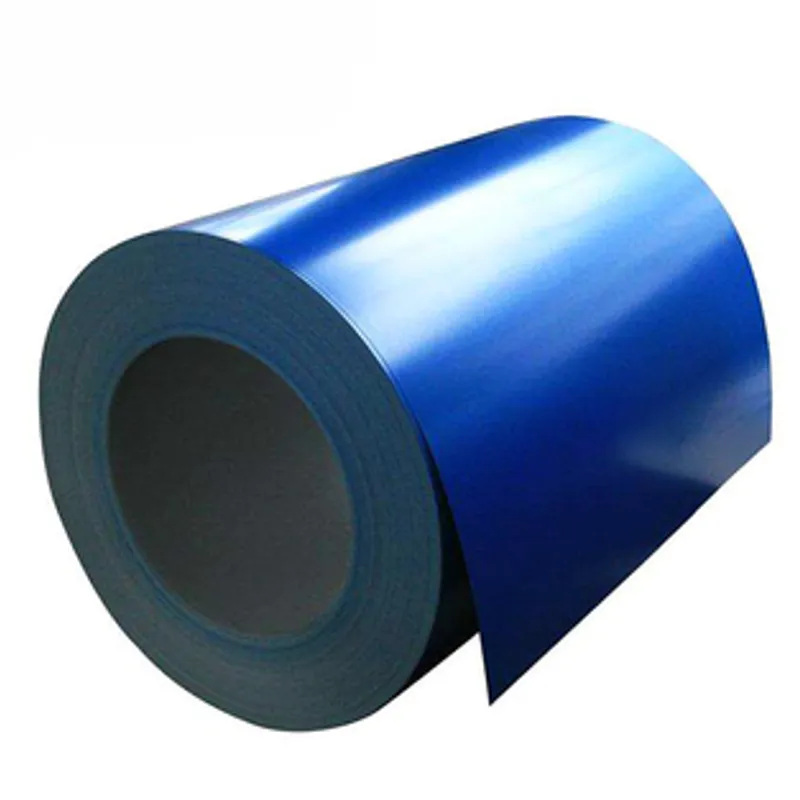

Corrosion resistance is the core advantage of PPGI, achieved through the synergistic effect of the galvanized zinc layer and the organic paint coating. The galvanization process deposits a zinc layer on the steel substrate, which protects the steel through two mechanisms: barrier protection, where the zinc physically separates the steel from the environment, and sacrificial protection, where zinc oxidizes preferentially to steel, even when the coating is scratched or damaged. This makes PPGI highly resistant to atmospheric corrosion, especially in environments with moisture, salts, or pollutants.The choice of zinc coating type can enhance corrosion resistance further. For example, zinc aluminum (Zn Al) alloys like Galvalume® offer superior corrosion resistance in coastal or industrial areas due to the aluminum’s ability to form a dense oxide layer that inhibits further corrosion. The paint system adds an additional barrier, resisting chemical attack and UV degradation that could compromise the zinc layer’s effectiveness. Modern coatings include corrosion inhibiting primers that enhance the bond between the zinc and topcoat while providing extra protection against crevice corrosion at cut edges or fastener sites.Corrosion resistance is tested using standardized methods such as the salt spray test (ASTM B117), where samples are exposed to a saline mist to simulate coastal or winter road conditions, and the cyclic corrosion test, which alternates between wet and dry phases to mimic real world environmental fluctuations. These tests help classify PPGI into corrosion resistance categories, allowing users to select the appropriate grade for their application. From agricultural buildings exposed to fertilizer salts to offshore structures in saltwater environments, PPGI’s corrosion resistance ensures long term reliability and reduced maintenance costs, making it a preferred material in any setting where metal degradation is a concern.