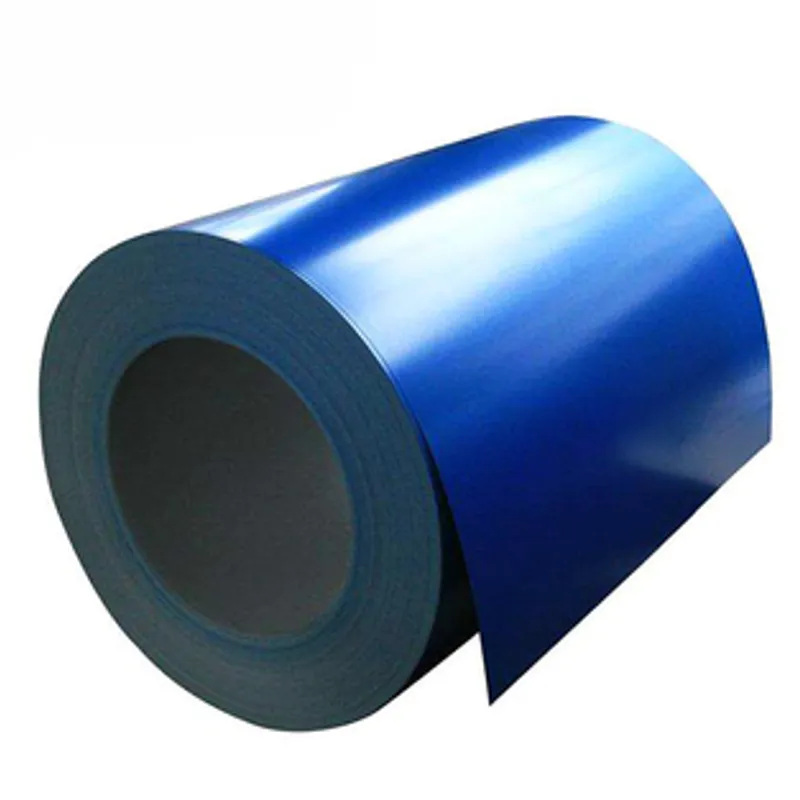

PPGI automotive sheets are specifically developed for use in vehicle manufacturing, where a balance of corrosion resistance, formability, and structural integrity is critical. In automotive applications, these sheets are used for body panels, chassis components, and internal structural parts. The key advantage lies in the pre painted finish, which eliminates the need for post painting during vehicle assembly, reducing manufacturing steps and costs while ensuring uniform coating quality.The galvanized layer in PPGI automotive sheets provides excellent protection against road salt, moisture, and debris, which are major causes of corrosion in vehicles. In regions with harsh winters, where roads are treated with de icing salts, the zinc coating acts as a first line of defense, preventing rust from forming on critical components like fenders and door panels. The paint layer adds an additional barrier, resisting scratches and UV damage that can lead to paint degradation and subsequent corrosion.Formability is another critical factor for automotive sheets. PPGI is engineered to have high ductility, allowing it to be stamped into complex shapes during the body panel forming process without cracking or coating delamination. The coating system is designed to withstand the mechanical stresses of deep drawing and stretch forming, maintaining both aesthetic and protective properties after fabrication. Additionally, the pre painted surface meets strict automotive standards for color consistency, gloss retention, and resistance to chemicals like motor oils and detergents, ensuring the vehicle’s appearance and durability over its service life.