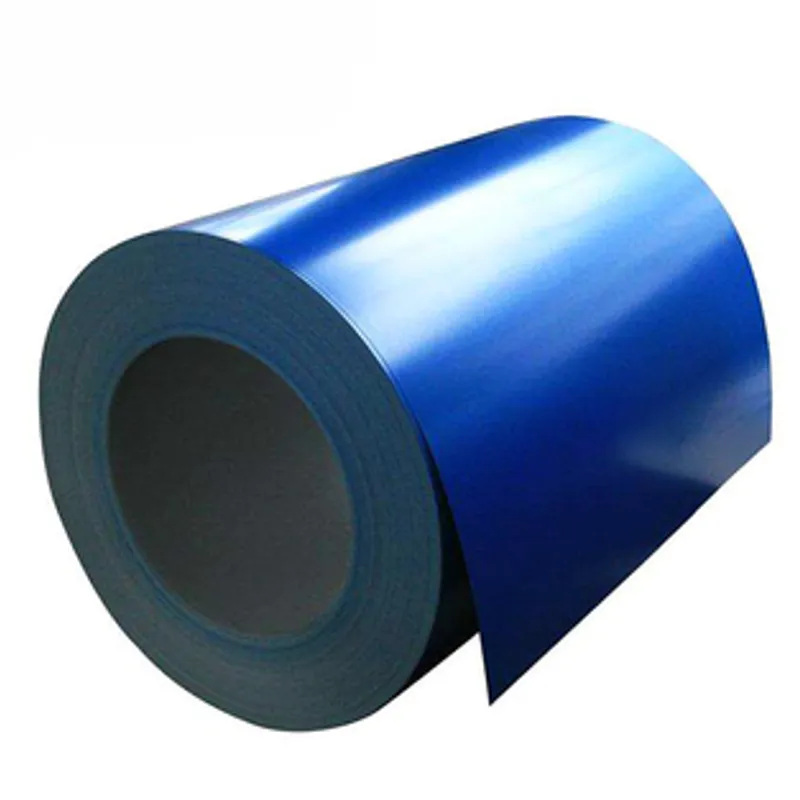

Durability in PPGI sheets encompasses resistance to multiple forms of degradation, including corrosion, abrasion, chemical exposure, and mechanical wear. The galvanized zinc layer provides the foundation for corrosion durability, as zinc naturally forms a protective patina that slows down oxidation. This is particularly important in industrial environments with airborne pollutants like sulfur dioxide or chloride ions, which can accelerate corrosion in unprotected metals.The paint layer adds another dimension of durability by resisting abrasion from wind driven debris, mechanical impacts, and chemical spills. In industrial settings, where equipment may come into contact with oils, solvents, or cleaning agents, the paint’s chemical resistance prevents staining and surface degradation. Additionally, the coating’s hardness and flexibility balance ensure it can withstand minor impacts without chipping, the crucial for applications like machine enclosures or industrial cladding.Durability testing for PPGI includes accelerated aging tests, where samples are exposed to high temperature humidity, UV radiation, and corrosive gases to simulate years of real world exposure. These tests help manufacturers validate the material’s lifespan under specific conditions, allowing customers to select the appropriate coating type and thickness for their needs. Whether used in agricultural facilities, where it may encounter fertilizer chemicals and moisture, or in manufacturing plants with heavy machinery, PPGI durable sheets maintain their functional and aesthetic properties through a combination of robust substrate protection and advanced coating technology.