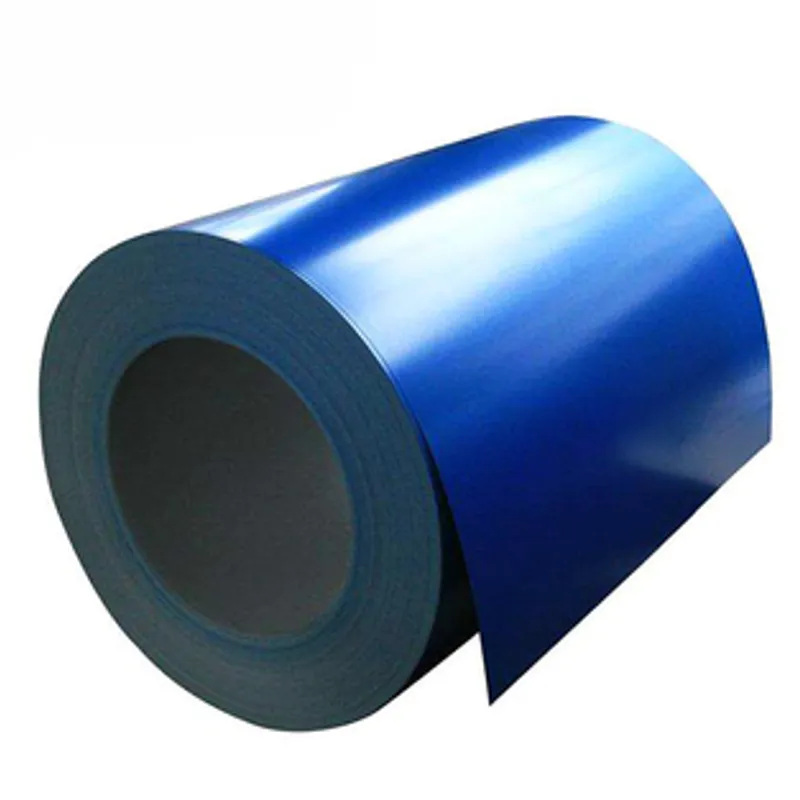

PPGI custom size sheets offer flexibility in meeting the specific dimensional requirements of various projects, eliminating the need for on site cutting and reducing material waste. Manufacturers can produce sheets in a wide range of widths (typically 600 1500 mm), lengths (up to 12 meters or more), and thicknesses (0.15 3.0 mm), depending on the production line capabilities. Custom sizing is particularly valuable in construction projects where standard sheet sizes may not fit architectural designs or structural specifications.The process involves precision slitting and cutting of large coils into the required dimensions, ensuring tight tolerances for width and length. For roofing applications, custom length sheets can span entire roof sections without seams, reducing the risk of leaks and improving installation efficiency. In modular construction or prefabricated buildings, where components are manufactured off site, exact dimensions are crucial for seamless assembly, and PPGI custom size sheets can be produced to match engineered drawings precisely.Custom sizing also allows for optimization of material usage, as sheets can be cut to minimize scrap during fabrication. For example, in a project requiring non standard panel sizes for cladding, producing custom sheets reduces waste compared to cutting standard sheets to size on site, which can be inefficient and lead to edge damage. Additionally, custom size sheets can be combined with other features like specific coating colors, surface textures, or enhanced mechanical properties, providing a tailored solution that meets both functional and aesthetic project requirements.