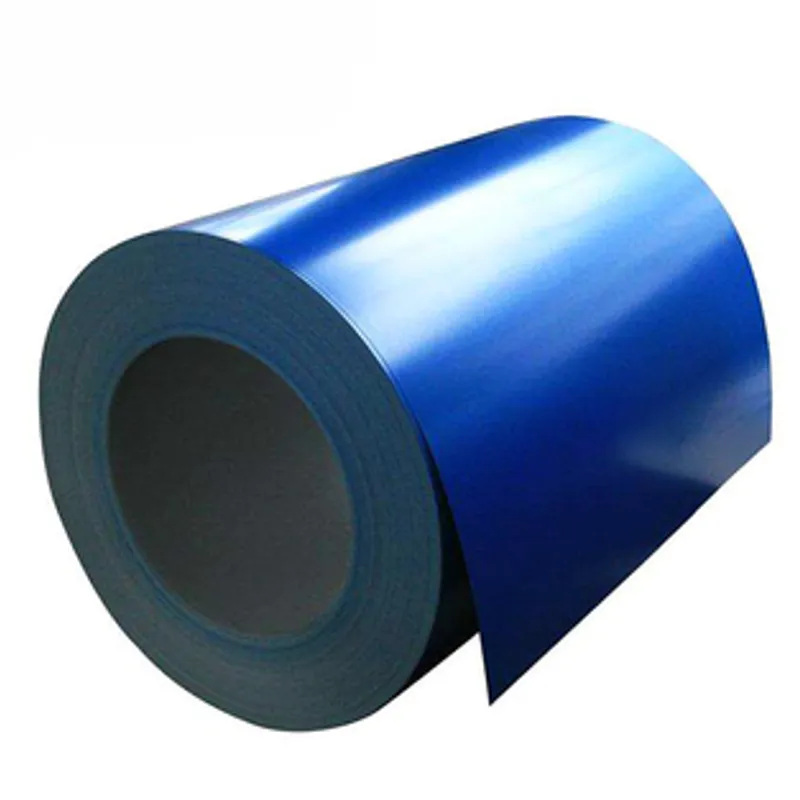

PPGI sheets are engineered to be highly weather resistant, capable of withstanding diverse climatic conditions ranging from tropical humidity to arid deserts and coastal salt laden environments. The weather resistance primarily stems from the combination of the galvanized zinc layer and the organic paint system. The zinc coating acts as a sacrificial barrier, protecting the steel substrate even when the paint layer is slightly damaged. Zinc’s electrochemical properties mean it oxidizes preferentially to steel, forming a protective zinc oxide layer that prevents further corrosion.Above the zinc layer, the paint system is crucial for weather resistance. Modern PPGI uses advanced coatings such as polyester, silicone modified polyester (SMP), or fluoropolymer (PVDF) paints, each designed for specific weather conditions. Polyester coatings offer good general weather resistance and color retention for moderate climates, while SMP coatings provide enhanced durability in harsher environments with UV exposure and temperature fluctuations. PVDF coatings, the most durable, are ideal for coastal areas or regions with high UV radiation, offering superior resistance to fading, chalking, and chemical erosion.Manufacturers also apply primer layers between the zinc and topcoat to improve adhesion and additional corrosion resistance. These multi layer systems undergo rigorous testing, including salt spray tests, UV exposure tests, and humidity resistance trials, to ensure compliance with international standards like ASTM D1654 or ISO 6270. In coastal zones, the combination of zinc’s anti corrosive properties and the paint’s ability to repel salt moisture makes PPGI a reliable choice for structures like port facilities and seaside buildings. In regions with heavy rainfall or freezing temperatures, the material’s resistance to water penetration and thermal expansion/contraction minimizes the risk of coating cracking or substrate damage, ensuring long term performance in dynamic weather conditions.