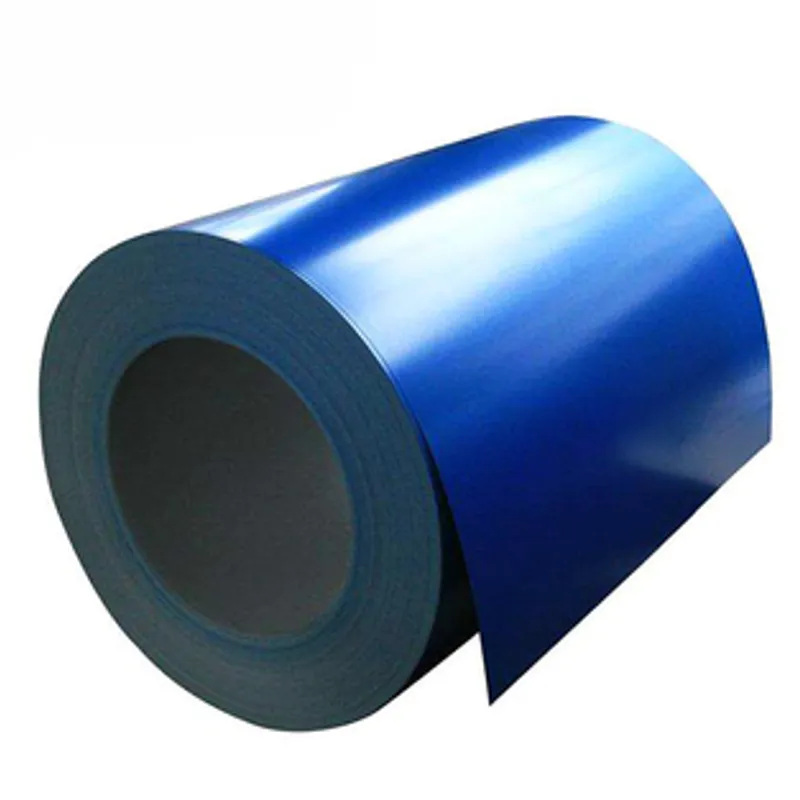

PPGI high strength sheets are designed to combine the protective benefits of pre painted galvanized steel with enhanced mechanical properties, making them suitable for load bearing applications. The strength is achieved through advanced steel alloying and processing techniques, such as using high strength low alloy (HSLA) steels or thermomechanical processing to increase yield and tensile strength without compromising formability.These sheets typically have yield strengths ranging from 250 MPa to over 550 MPa, depending on the grade, allowing them to support heavier loads in structures like industrial roofing, structural framing, and transportation equipment. The high strength reduces the required thickness of the sheet, enabling material savings while maintaining structural integrity. For example, in a warehouse roof design, using high strength PPGI can allow larger spanning distances between supports, reducing the number of purlins needed and lowering overall construction costs.The coating system on high strength PPGI is specially formulated to withstand the stresses associated with forming and loading. During roll forming or stamping, the coating must not crack or peel, which requires excellent ductility and adhesion. Manufacturers achieve this by optimizing the zinc layer’s surface treatment and the paint’s flexibility, ensuring the coating remains intact even when the steel is subjected to significant mechanical deformation. In applications like truck trailers or storage racks, where the material is exposed to dynamic loads and potential impacts, the combination of high strength and durable coatings ensures both structural safety and long term resistance to environmental damage.