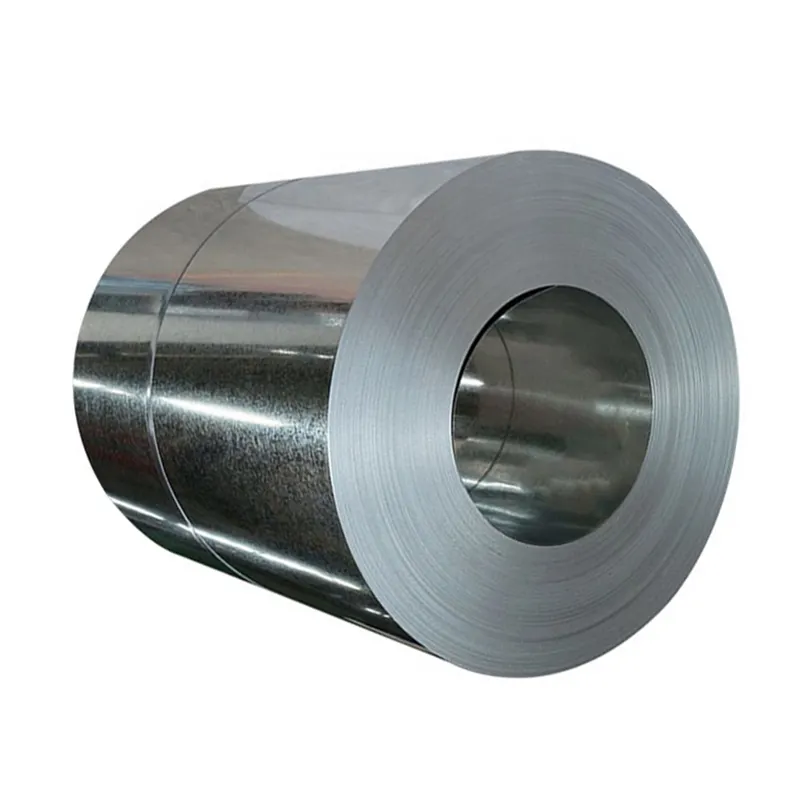

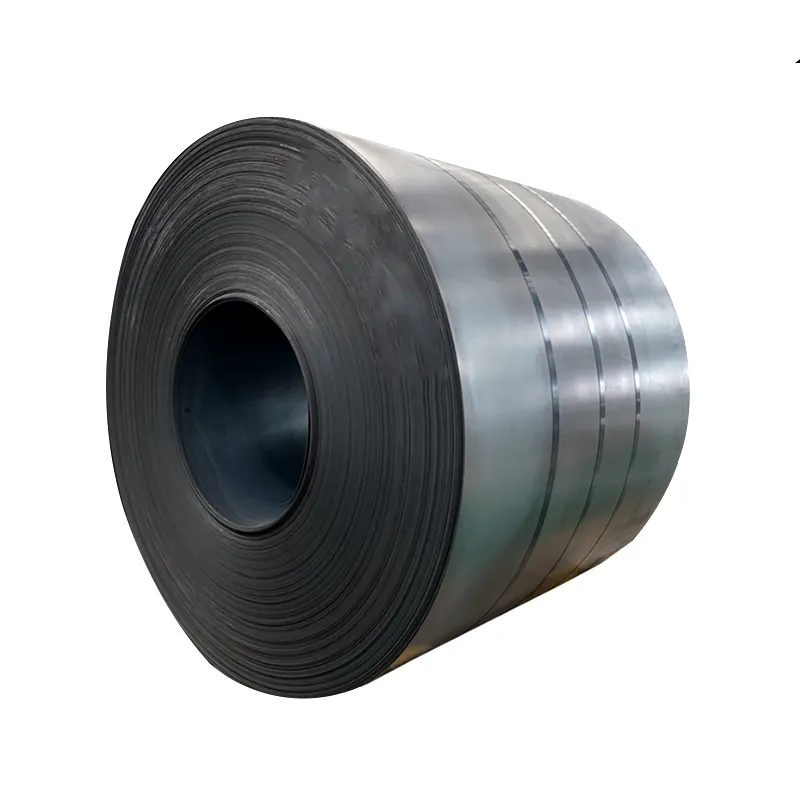

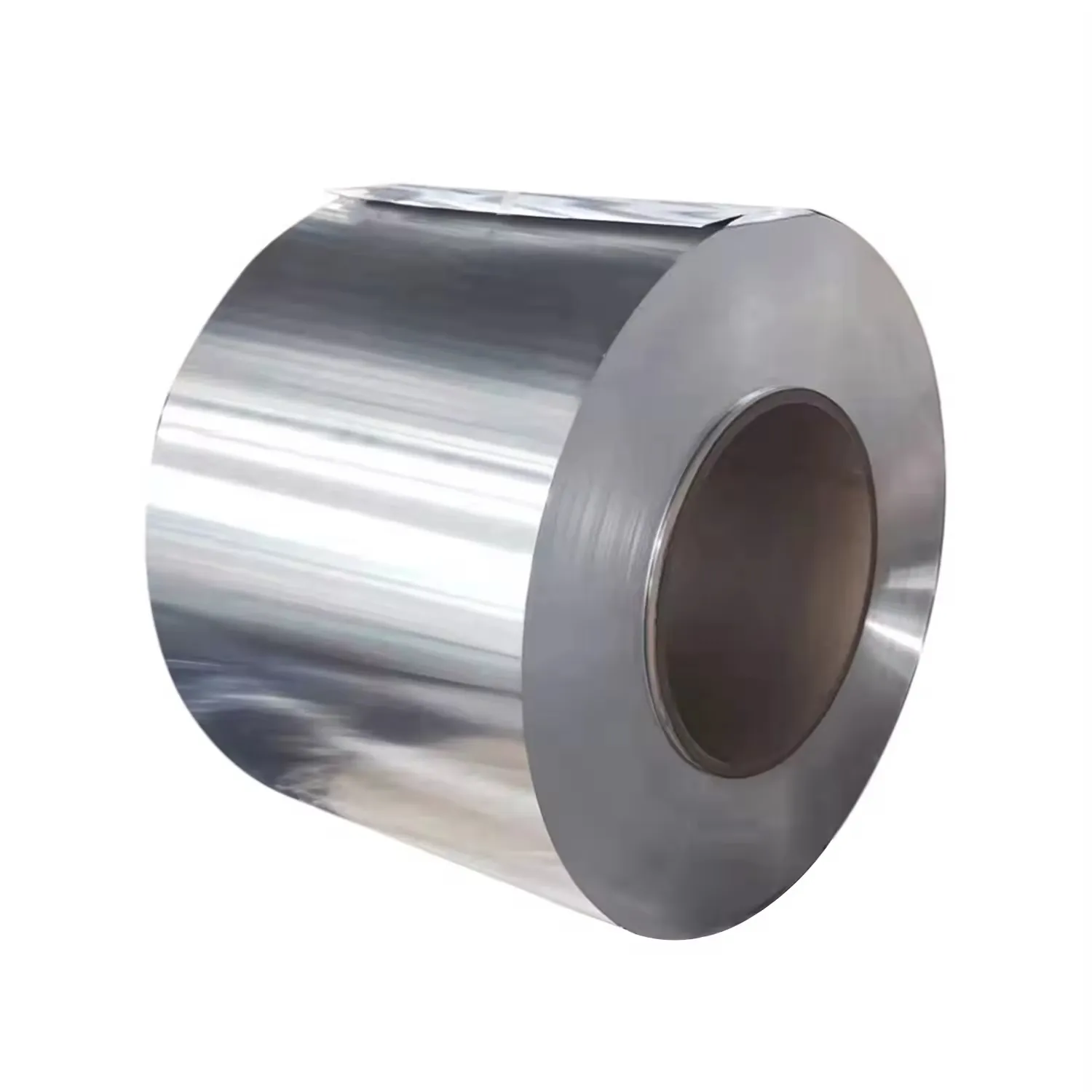

Carbon steel coil sheet refers to thin gauge carbon steel coils typically ranging from 0.1mm to 6mm in thickness, renowned for their formability, surface precision, and versatile applications. These coils are produced through cold rolling or hot rolling, with cold rolled sheets offering superior dimensional accuracy and a smooth surface finish, while hot rolled sheets feature better ductility for general forming. The carbon content is usually controlled below 0.25% for low carbon sheets, ensuring excellent weldability and stamping performance. Mechanical properties such as tensile strength (400 550 MPa) and yield strength (235 355 MPa) are optimized for lightweight structural applications. Surface treatments like pickling, galvanizing, or painting are commonly applied to enhance corrosion resistance and aesthetic appeal. Carbon steel coil sheets are widely used in automotive body panels, home appliance casings (refrigerators, washing machines), electronic enclosures, and architectural cladding. Their thin gauge allows for complex stamping into intricate shapes, while the coil form enables continuous manufacturing processes to reduce material waste. Quality control involves strict checks on thickness uniformity, surface defects, and mechanical properties, with standards like ASTM A6 and JIS G3141 governing specifications. As industries demand lighter, more efficient products, carbon steel coil sheets continue to evolve with advancements in high strength low alloy formulations and precision rolling technologies.