Site Assessment and Pre-Installation Planning for Steel Sheet Pile Projects

Soil Analysis, Groundwater Evaluation, and Load-Bearing Capacity Determination

A good site assessment really sets things up right when installing steel sheet piles. Looking at soil composition and layers helps figure out what kind of pile to use, how deep it needs to go, and which driving technique works best. Checking groundwater levels and where water flows tells engineers about potential pressure issues and risks from water seeping through. To measure how much weight the ground can take, there are standard tests involved. The SPT test works well for gravelly soils while the CPT test suits finer materials or mixed ground conditions. Both methods are recognized industry standards according to ASTM D1586 and ISO 22476-1 guidelines. All these checks make sure the ground beneath can handle not just the immediate installation forces but also whatever structural stress comes along later. Practical experience shows that clayey soils usually need some pre-drilling or less powerful hammers to avoid sideways movement problems. Sandier or rocky soils generally let crews drive the piles straight in with vibration equipment without extra complications.

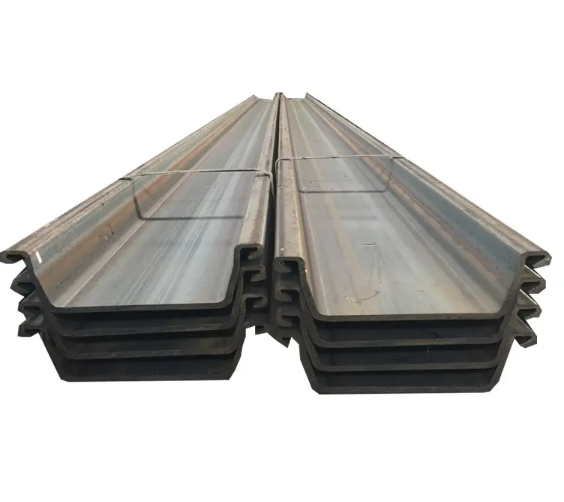

Interlock Testing, Orientation Alignment, and Driving Guide Setup

Before installing anything, we check interlock integrity through visual inspections and trial fits of sample sections. This helps spot any deformities, signs of corrosion, or manufacturing flaws that might affect how watertight everything stays or disrupt structural continuity. Keeping things straight vertically matters too, so we stick to about a 1:100 tolerance range using those laser alignment systems that get set against control points on site. For the first few piles, temporary steel guides play a big role. These guides need solid anchoring either into stable ground or whatever temporary structures we have available. They establish where everything starts, make sure it's plumb, and handle the angle (batter) properly. Having this reference system really pays off when looking at the whole wall alignment. We see around 30% fewer corrections needed after installation compared to just doing it freehand. The placement of these guides isn't random either. We position them carefully to work around whatever obstacles exist on site while still maintaining the original design shape and making sure the load paths stay intact as intended.

Steel Sheet Pile Installation Methods and Equipment Optimization

Vibratory, Impact, Hydraulic Pushing, and Jetting: Matching Technique to Soil Profile

What works best for installing these systems depends mostly on what's underneath the ground rather than how much money we have or what equipment happens to be around. Vibratory hammers work really well in places with sand and gravel because their fast shaking movements lower the friction against the pile surface, letting them go deeper faster without causing much vibration. For tougher situations like dense clay or areas with rocks mixed in, impact hammers are better since they can handle those harder materials but come with the need for extra care around nearby buildings to manage vibrations properly. Hydraulic pressing pushes piles down using steady pressure, which makes it great for cities or neighborhoods where too much noise or shaking would be a problem, especially in softer soils that hold together better. There's also jetting, which isn't used all that often but can help sometimes by shooting water down at the bottom of the pile to make sandy ground act like liquid for a while, cutting resistance during installation by maybe as much as half in tough spots. Still, this needs careful control of underground water levels to prevent issues later on. Getting this right starts with good soil testing reports. Using the wrong technique just wastes time and money. Some projects end up costing 40% more simply because someone ignored what kind of dirt was actually there beneath the surface.

Equipment Selection Criteria, Maintenance Protocols, and Over-Water Adaptation

Choosing the right equipment involves looking at several key factors including how resistant the soil is, the shape of the piles, whether machinery can get to the site, and any environmental restrictions that might apply. When it comes down to specifics, there are three main things engineers focus on: making sure the hammer has enough energy to handle the resistance needed according to standards like EN 1997-1 Annex A, checking if cranes can lift those interlocked sections safely while accounting for extra forces during operation, and integrating sensors that monitor alignment, torque levels, and how fast the pile goes into the ground. Regular maintenance work cannot be overlooked either. Hydraulic systems need special attention because they're so crucial to everything working properly. Hammer anvils wear out over time and must be checked regularly too. Crane rigging components should follow manufacturer recommendations strictly. Daily checks with proper documentation of inspections and lubrication records help keep everything running smoothly without unexpected breakdowns.

When working in marine or tidal environments, equipment faces some serious challenges from corrosion, constant wave movement, and unpredictable support structures beneath the water. Modern barges now come fitted with GPS guided piling systems that keep their position remarkably stable, staying within about 25mm accuracy even when currents start to pick up. To fight off rust and degradation, most setups use special marine alloys like ASTM A690 Corten steel alongside proper cathodic protection methods that meet NACE SP0169 standards. The hardware itself needs protection too, which is why sealed lubricant systems and pressure tested guides are so important. These features stop water from getting into critical components during installation under water, something absolutely essential for maintaining the structural integrity of retaining walls and cofferdams in saltwater conditions.

Installation Sequence, Quality Control, and Structural Integrity Assurance

Following a properly ordered installation sequence helps avoid problems like cumulative misalignment, damage to interlocks, and unexpected disturbances in the soil. The process usually starts by checking where guides are placed and confirming pile orientation first. Then comes the phased driving stage, which often begins at corners or anchor points so the overall geometry gets locked in place early on. During all this, real time monitoring keeps an eye on things like vertical alignment, rotational movement, and how resistant the ground is to penetration. If measurements drift beyond about half a percent either way, corrections need to happen right away before moving forward with the next steps.

After driving operations, quality control involves checking how well the interlocks fit together visually, using ultrasonic equipment to spot any hidden deformations or problems with welds, and making sure everything lines up correctly through surveys that should stay within 1% of the original design specs. When it comes to structural validation, engineers perform static load tests following ASTM D1143 standards to see if the structure can handle the expected weight. They also run finite element analysis (FEA) simulations to understand where stresses might build up. These stress points often appear at corners, where tiebacks connect, or when different soil layers meet. All the important data gets recorded digitally including torque measurements, logs showing how much resistance the soil offered during installation, and notes on any deviations observed. These records follow industry standards like ASTM A328 for steel sheet piling work and EN 12063 guidelines for retaining structures. Having all this information documented properly makes it easier for outside experts to review the work and ensures we meet all necessary regulations. Putting all these steps together actually cuts down the chances of structural failures by around 34% compared to projects where these checks aren't done systematically or at all.

Common Challenges and Proven Mitigation Strategies in Steel Sheet Pile Installation

Installing steel sheet piles efficiently requires foresight into potential obstacles and strategic planning to overcome them. Common issues include unexpected obstructions, unstable soil conditions, and stringent regulatory requirements. Addressing these proactively minimizes delays, cost increases, and structural failures. The following strategies are industry-proven for maintaining project timelines and integrity.

Dealing with Obstructions, Poor Soil Cohesion, and Regulatory Compliance Constraints

Unexpected obstacles like rocks, hidden pipes, or leftover construction stuff often slow down the whole process. Getting ahead of these problems means digging down past where they sit, then using either jetting techniques or those special high torque vibrating tools to either get around them safely or break them apart. When dealing with soils that stick together well, jetting really cuts down on resistance during installation. Still important though to keep track of sediment when doing this near any bodies of water so we don't end up polluting our streams and rivers.

When dealing with soils that lack proper cohesion like loose sands or silty materials, there's simply a higher chance of encountering problems with wall stability plus increased seepage issues. To combat this, various ground improvement methods come into play. Cement grouting works well here, as does deep soil mixing or even vibro compaction techniques which help boost lateral support while cutting down on permeability before any piling work begins. Sometimes just going deeper isn't enough though. That's when additional lateral supports become necessary. Think wales, rakers, or those tieback systems we've all seen at construction sites. These aren't just random additions but are carefully planned based on what the actual soil conditions show during testing and how it behaves under different loads. Most experienced engineers know this from years of fieldwork.

Meeting regulations around noise levels, vibrations, dust control, and environmental effects needs planning ahead of time. Hydraulic pressing is one quiet method that works well under tight city noise rules such as those found in the EU Directive 2002/49/EC. At the same time, keeping track of vibrations through real time monitoring helps stay within what local governments require according to standards like DIN 4150-3. Getting permit offices involved early on makes things smoother later. Sending them detailed reports about how projects might affect the environment and building plans that include flexible management strategies can save headaches down the road. Nobody wants to deal with work stops or expensive changes after construction has already started.