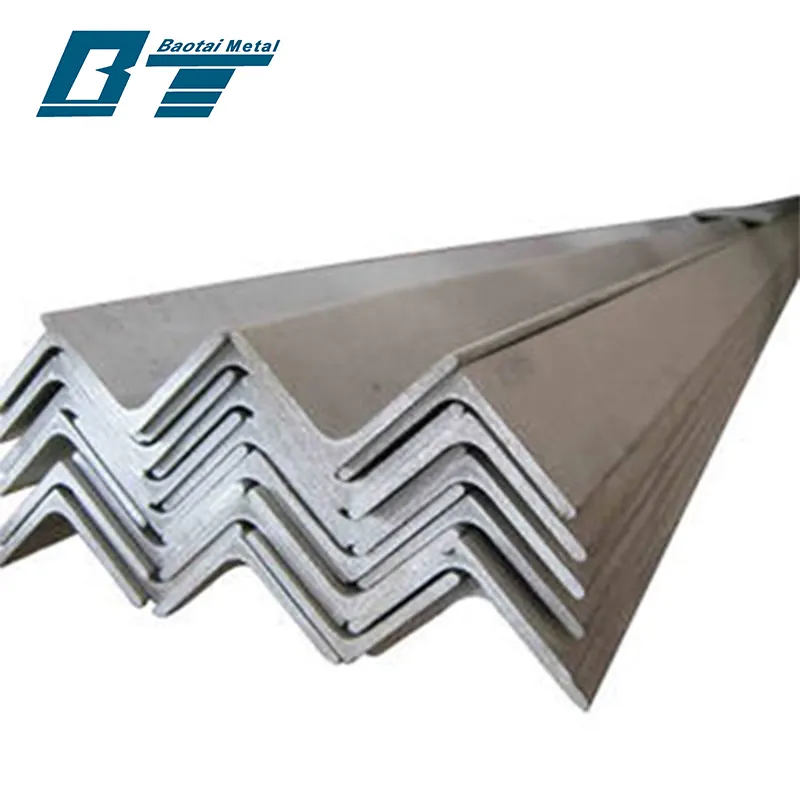

Bariga xaalad ah ee carruurta ah u talagalay meelaha carruurtanka ah waxaa lagu sameeyay ku saabsan carruurka ah oo ka mid ah degmada carruurtanka, si aysata dhammaystirka carruurta iyo ugu yarreey inta badan manufacturing carruurta. Carruur carruursan waxaa la baxay bilowtii carruurta ah 1,100–1,300°C, markaasuu ka soo diray rolling mills carruurta ah ku jira L shape. Waxbarasho carruurta ah ee carruurta ah waxaa la kala qeybinayaa dabka looga tagay stress dheer iyo waxaa la yidhi inuu ugu yarreey production runs dheer, si ay carruur bariga xaalad ah ee carruurta ah ku jiro ideal marka haddii macluumaaddeedna waa inay u baahan tahay tolerances mar kale ee cost iyo availability. Grades carruurta ah ee ASTM A36 waxaa ku jiray tensile strengths 400–550 MPa iyo yield strengths ≥250 MPa, ee ku yimid sida macluumaaddeed ee construction iyo industrial supports. Surface finish carruurta ah waxaa lahayd scale carruurta ah ee carruurta ah ee ku jiro pickling ama uu ka jiro kuna fiicaninayaa applications ee aan u baahan tahay appeal aesthetic. Bariga xaalad ah ee carruurta ah waxaa la yiri doonaa inuu uga soo galo equipment carruurta ah ee carruurta ah, temporary construction supports, iyo non load bearing architectural elements. Formability carruurta ah waxaa la yiri doonaa inuu uga soo galo on site bending ama cutting carruurta ah carruurta ah sidoo kale ee tools specialized, markaasuu work hardening carruurta ah ee carruurta ah carruurta ah waxaa la yiri doonaa inuu uga soo galo annealing carruurta ah shapes complex. Markaasaa dimensional tolerances carruurta ah waxaa loo yaqaano loose cold rolled products, carruur carruurta ah waxaa loo sameeyo method preferred carruurta ah legs over 150mm due to cost iyo feasibility production.