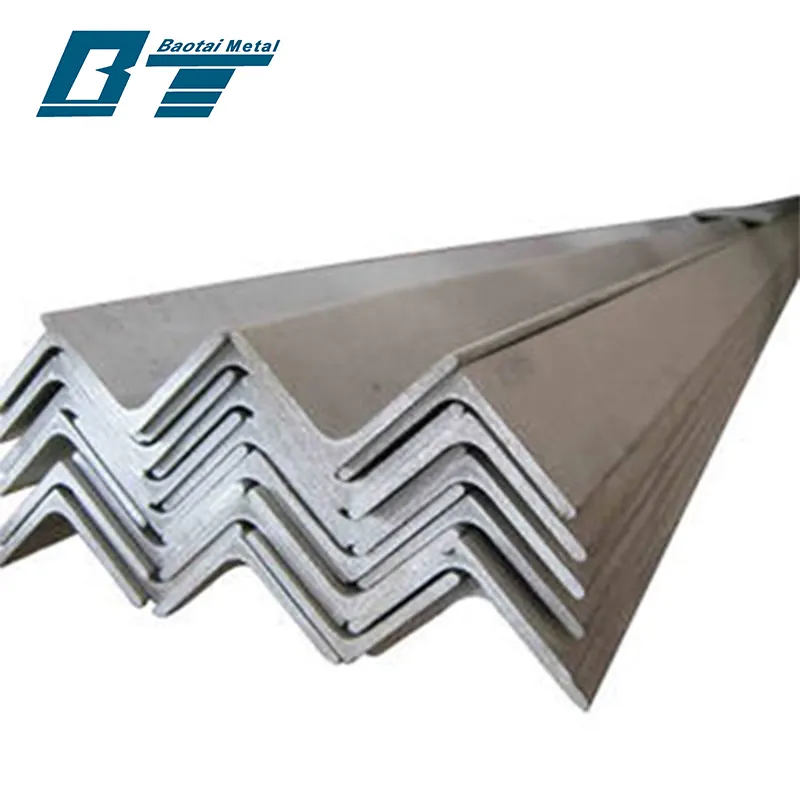

Hot rolled angle bar is produced by deforming steel at temperatures above its recrystallization point, resulting in enhanced ductility and cost effective large scale manufacturing. The process begins with reheating billets to 1,100–1,300°C, followed by passing through rolling mills to form the L shape. This high temperature processing reduces internal stresses and allows for larger production runs, making hot rolled angle bars ideal for non critical structural applications where tight tolerances are secondary to cost and availability. Common grades like ASTM A36 exhibit tensile strengths of 400–550 MPa with yield strengths ≥250 MPa, suitable for general construction and industrial supports. The surface finish may retain a scale from the hot rolling process, which can be removed via pickling or used as is for applications not requiring aesthetic appeal. Hot rolled angle bars are widely used in agricultural equipment, temporary construction supports, and non load bearing architectural elements. Their formability allows for on site bending or cutting without specialized tools, though work hardening during cold fabrication may require annealing for complex shapes. While dimensional tolerances are looser than cold rolled products, hot rolling remains the preferred method for large diameter angle bars (legs over 150mm) due to cost and production feasibility.